- Product Details

- {{item.text}}

Quick Details

-

Power:

-

option

-

Dimension(L*W*H):

-

option

-

Weight:

-

1000 kg

-

Model:

-

VS4.8x74

-

Diameter(m):

-

4.8

-

Length(m):

-

74

-

Slope(%):

-

4

-

Capacity(t/d):

-

5000

-

Rotary Speed(r/min):

-

0.396-3.96

-

Power(kW):

-

630

-

Weight(t):

-

899

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

VOSTOSUN

-

Voltage:

-

220/380V

-

Power:

-

option

-

Dimension(L*W*H):

-

option

-

Weight:

-

1000 kg

-

Model:

-

VS4.8x74

-

Diameter(m):

-

4.8

-

Length(m):

-

74

-

Slope(%):

-

4

-

Capacity(t/d):

-

5000

-

Rotary Speed(r/min):

-

0.396-3.96

-

Power(kW):

-

630

-

Weight(t):

-

899

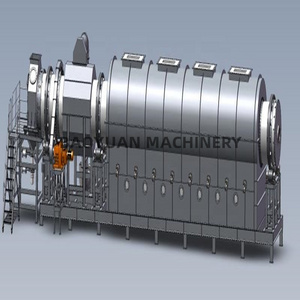

Product Overview

Rotary Kiln

Rotary Kiln means rotary calcining kiln, it can be divided into cement kiln, metallurgical and

chemical kiln and active-lime kiln according different materials being processed.

Cement Kiln is mainly used for calcina

ting clinker and it has dry type and wet type.

Metullurgical and chemical kiln is mainly used for poor iron ore magnetization calcination, the oxidizing calcination of chromium ore, ferron

ickel ore; the calcination of high aluminum bauxite ore in the refractory material factory and aluminum hydroxide, the clinker, aluminum hydroxide calcination in the aluminum plant; the calcination of chrome ore and chrome powder in the chemical plant, etc.

Active-lime kiln is used for the calcination of active-lime and dolomite in the steel making factory

and iron alloy factory.

FEATURES AT A GLANCE

Working Principle

Material is fed into kiln though end of kiln (higher side of cylinder). Because cylinder is inclined and it rotates slowly, material moves along with circle as well as axial direction (from higher side to lower side). After going through physical and chemical change, material gets into cooling machine through head cover of kiln after the finishing calcination. Fuel is fed into

the kiln head through the kiln head, and exhaust gas will discharge at the end of kiln after exchanging heat with material.

PRODUCT SPECIFICATIONS

PRODUCT CONFIGURATION

SALES AND SERVICE NETWORK

Packing And Shipping

Industrial Drying Equipment

Stone Crushing & Screening Equipment

Mineral processing equipment

Grinding Equipment

Gypsum Board Machinery

Gypsum Powder Production Plant

Hot Searches