- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

cryogenic cooling circulation pump

-

Temperature Range:

-

-40℃-RT

-

Fluctuation:

-

±0.1℃

-

Rated Flow Rate:

-

25L/min

-

Tank volume:

-

3~100 L

-

Operation:

-

Multiple operation modes

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Total Power:

-

0.9KW-10.6KW

-

Voltage:

-

220V, 380V

Quick Details

-

Weight (KG):

-

45

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

YHCHEM

-

Product name:

-

cryogenic cooling circulation pump

-

Temperature Range:

-

-40℃-RT

-

Fluctuation:

-

±0.1℃

-

Rated Flow Rate:

-

25L/min

-

Tank volume:

-

3~100 L

-

Operation:

-

Multiple operation modes

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Total Power:

-

0.9KW-10.6KW

-

Voltage:

-

220V, 380V

Technical Specification

|

Model |

YLT-0540 |

YLT-1040 |

YLT-2040 |

YLT-3040 |

YLT-5040 |

YLT-10040 |

YLT-20040 |

YLT-30040 |

YLT-50040 |

|

Temperature Range(℃) |

-40-RT ; ±1 ℃ |

||||||||

|

Ambient Temperature (℃) |

≤30℃ |

||||||||

|

Voltage (V) |

220 |

380 |

|||||||

|

Phase No (P) |

1 |

3 |

|||||||

|

Frequency (HZ) |

50 |

50/60 |

|||||||

|

Total Power (Kw) |

0.9 |

1.3 |

2.4 |

3.2 |

5.75 |

6.3 |

8 |

10.6 |

10.6 |

|

Cooling Capacity ( W ) RT |

1900 |

2800 |

5625 |

7500 |

12775 |

16500 |

31438 |

40015 |

40015 |

|

Cooling Capacity( W ) 0℃ |

1000 |

2500 |

4600 |

6180 |

11275 |

14600 |

13538 |

22887 |

22887 |

|

Cooling Capacity ( W ) -40 ℃ |

170 |

550 |

900 |

900 |

650 |

900 |

2854 |

4162 |

4162 |

|

Temperature Sensor |

PT100 |

||||||||

|

Safety Protection |

Overvoltage, delay, overcurrent, overheating, leakage, protector |

||||||||

|

Compressor Refrigerant |

R404A |

||||||||

|

Chiller Type |

Air cooling |

||||||||

|

Circulating Pump Rated lift (M) |

6 |

12 |

9.7 |

||||||

|

Circulating Pump Rated flow (L/min) |

25 |

35 |

97 |

35 |

35 |

||||

|

Net Weight( Kg ) |

45 |

120 |

96 |

105 |

220 |

268 |

430 |

490 |

490 |

YLT (closed type) series low temperature cooling circulation pump is suitable for chemical, biological and physical testing and testing that need to maintain low temperature conditions. lt can be used in medicine and hygiene,food hygiene, chemical industry and laboratories in universities or research institutes. lt can be used with 10L,20L, 50L100L and other reaction kettles.

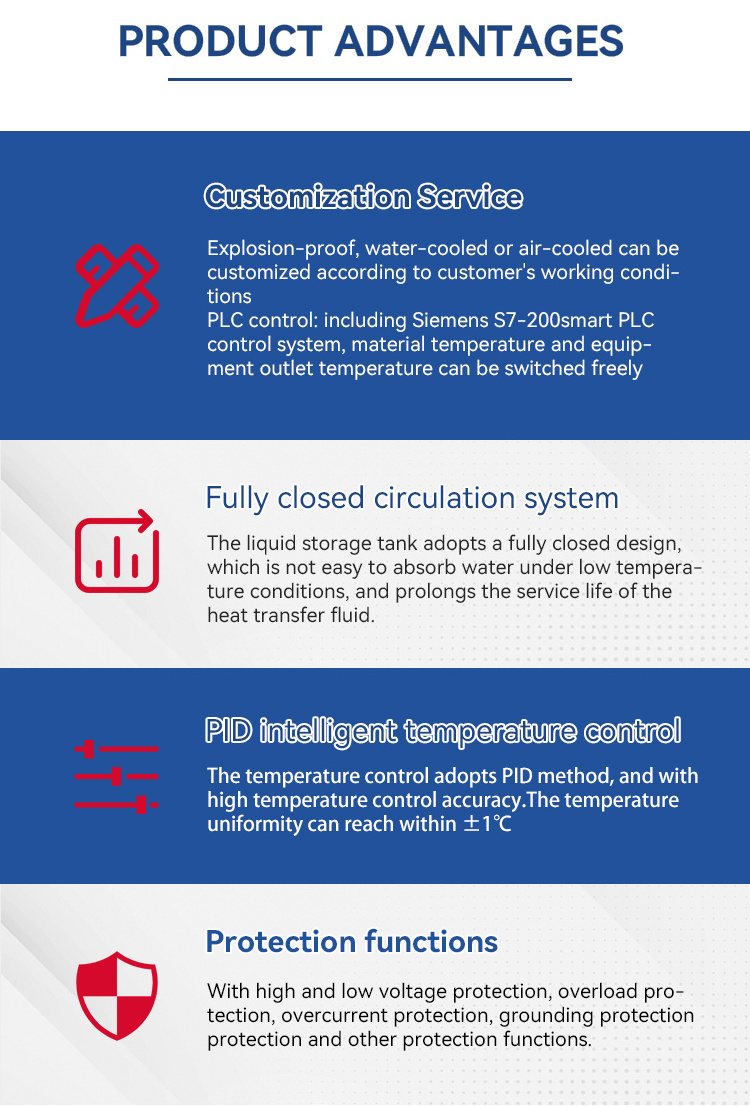

♣1.Customization Service

Explosion-proof, water-cooled or air-cooled can be customized according to customer's working condi-tions PLC control: including Siemens S7-200 smart PLC control system, material temperature and equipment outlet temperature can be switched freely

♣2.Fully closed circulation system

The liquid storage tank adopts a fully closed design, which is not easy to absorb water under low temperature conditions, and prolongs the service life of the heat transfer fluid.

♣3.PID intelligent temperature control

The temperature control adopts PID method, and with high temperature control accuracy.The temperature uniformity can reach within +1°C

♣4.Protection functions

With high and low voltage protection, overload protection, overcurrent protection, grounding protection protection and other protection functions.

♣1.Provide working condition:Industry, support equipment type

♣2.Supporting equipment model and size

♣3.Working temperature range

♣4.Select the model

♣1.Adopt microcomputer control, all digital display,easy to operate

♣2.Refrigeration system compressors, oil separators,solenoid valves, expansion valves, etc. are all imported brands

♣3.The use of fluorine-free environmentally friendly refrigerants, in line with international environmental protection refrigeration standards

♣4.The refrigerant outlet is equipped with apressure gauge, which can display the pressure of the refrigerant at the outlet.

♣5.Special circulating pump for low temperatureno leakage and no stall phenomenon under

♣6.A filter device is installed in the circulation pipe to prevent clogging of the circulation pipe

♣7.The evaporator is a fully brazed plate heat exchanger.

♣8.The liquid storage tank and circulation pipe line are made of 304 stainless steel, which has good corrosion resistance.

♣9.The left and right side panels are easy to disassemble, which is convenient for equipment maintenance

♣10.The shell adopts electrostatic plastic spray SPCC, which has good anti-corrosion effect.

♣1.Reactor

♣2.Molecular Distillation System

♣3.Rotary Evaporator