- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

1500 ml

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

BAOGE

-

Year:

-

2019

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

3500*1500*2200 MM

-

Hollow part volume:

-

100-1500 ml

-

Clamping Force (kN):

-

1500

-

Power (kW):

-

18

-

Weight (KG):

-

3550 KG

-

Name:

-

BG-4000

-

Blow Moulding Type:

-

Stretch Blow Moulding

-

After-sales Service Provided:

-

Free spare parts

-

Key words:

-

plastic bottle making machine

-

Suitable bottle:

-

PET Bottle

-

Machine color:

-

Custoemer Requirement

-

Capacity:

-

4500 BPH

-

Machine size:

-

3500*1500*2200 MM

-

Machine weight:

-

3000 KG

-

Machine power:

-

18 KW

Quick Details

-

Neck Diameter(mm):

-

38 mm

-

Max.Bottle Diameter(mm):

-

105 mm

-

Max.Bottle Height(mm):

-

330 mm

-

Bottle Volume(ml):

-

1500 ml

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

BAOGE

-

Year:

-

2019

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

3500*1500*2200 MM

-

Hollow part volume:

-

100-1500 ml

-

Clamping Force (kN):

-

1500

-

Power (kW):

-

18

-

Weight (KG):

-

3550 KG

-

Name:

-

BG-4000

-

Blow Moulding Type:

-

Stretch Blow Moulding

-

After-sales Service Provided:

-

Free spare parts

-

Key words:

-

plastic bottle making machine

-

Suitable bottle:

-

PET Bottle

-

Machine color:

-

Custoemer Requirement

-

Capacity:

-

4500 BPH

-

Machine size:

-

3500*1500*2200 MM

-

Machine weight:

-

3000 KG

-

Machine power:

-

18 KW

Products Description

Features of main body :

1). Stable performance with advanced PLC.

2). Automatic preform conveyer to save human cost.

3). Preform self-rotation and infrared pre-heater revolution assure the even distribution of heat, which improve the bottle shaping rate, increase the production.

4). High adjusting performance to enable preheat the preforms perfectly by adjust the voltage control area in the PLC, which could adjust the temperature of the infrared lights in the pre-heater, and keep the proper temperature and humidity invariable.

5). High safeties with security automatic-locking device in each mechanical action, which will make the production into a perfect safe environment, in case of the breakdown in certain procedure.

6). Introduce the FESTO air cylinder to avoid contamination and noise.

7). Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

8). Strong clamping force with high pressure and double crank links to lock the mould.

9). Two ways of operating: automatic and manual.

10). Low cost,high efficiency,easy operation and maintenance etc, profited from the fully automatic technological process.

11). Ideal cooling system make the finished bottles without any flaws.

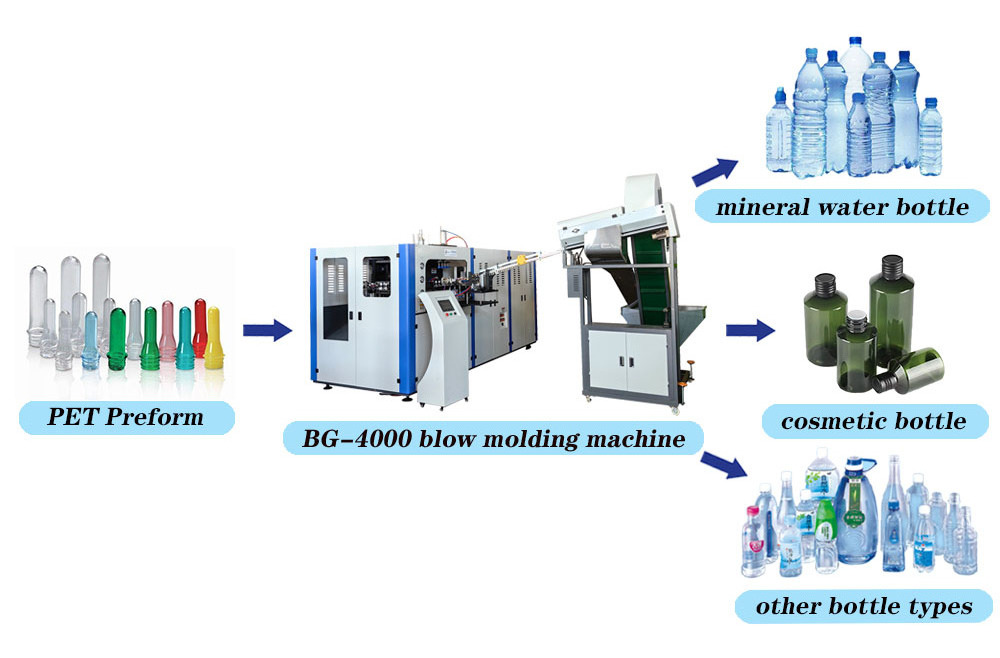

What We Can Blow

Taizhou Baoge can produce

various shapes and sizes of plastic bottles and containers

, including but not limited to:

-

Round Bottles

: Fully automatic blow molding machines can produce round bottles in various shapes and sizes, such as water bottles, juice bottles, soda bottles, etc.

-

Square Bottles

: Fully automatic blow molding machines can also produce square or rectangular bottles, which are commonly used for shipping liquid detergents, cleaning agents, soap solutions, etc.

-

Oval Bottles

: Fully automatic blow molding machines canproduce oval-shaped bottles, which are commonly used for personal care products such as cosmetics, body washes, shampoos, etc.

-

Irregular-Shaped Bottles

: In addition to the above shapes, fully automatic blow molding machines can also produce bottles withunique shapes, such as flat bottles, triangular bottles, hexagonal bottles, etc.

In reality, we can produce many different shapes and sizes of bottles, depending on its design and configuration.

If you have any questions, please contact us.

|

Model

|

BG-4000 Cheapest 4 Cavities Full Automatic Beverage Water PET Plastic Bottle Blowing Molding Machine , Blow Moulding Machine Price

|

|

|

|

Theoretical output

|

4500 pcs/h

|

|

|

|

|

Max. bottle volume

|

1.5 Liters

|

|

|

|

Max. neck diameter

|

38 mm

|

|

|

|

Max. bottle diameter

|

105mm

|

|

|

|

Max. bottle height

|

330 mm

|

|

|

|

Cavity

|

4

|

|

|

|

Automatic Lubricating Oil System

|

Yes

|

|

|

|

Mold thickness

|

180mm-240 mm

|

|

|

|

Open stroke

|

130 mm

|

|

|

|

Power voltage

|

380v/3Phase/50HZ

|

|

|

|

Installation power

|

40 kw

|

|

|

|

Actual power consumption

|

18kw

|

|

|

Air source

|

Recommend air compressor

|

3.2 m³/min 30Kg

1.6 m³/min 12Kg

|

|

|

Cooling water

|

Recommend water chiller

|

5HP

|

|

|

Blower size

|

Length*width*

height/weight

|

3500*1500*

2200 (MM)/3000 KG

|

|

|

Preform Loader size

|

Length*width*

height/weight

|

1750*960*

2500 (MM)/550kg

|

|

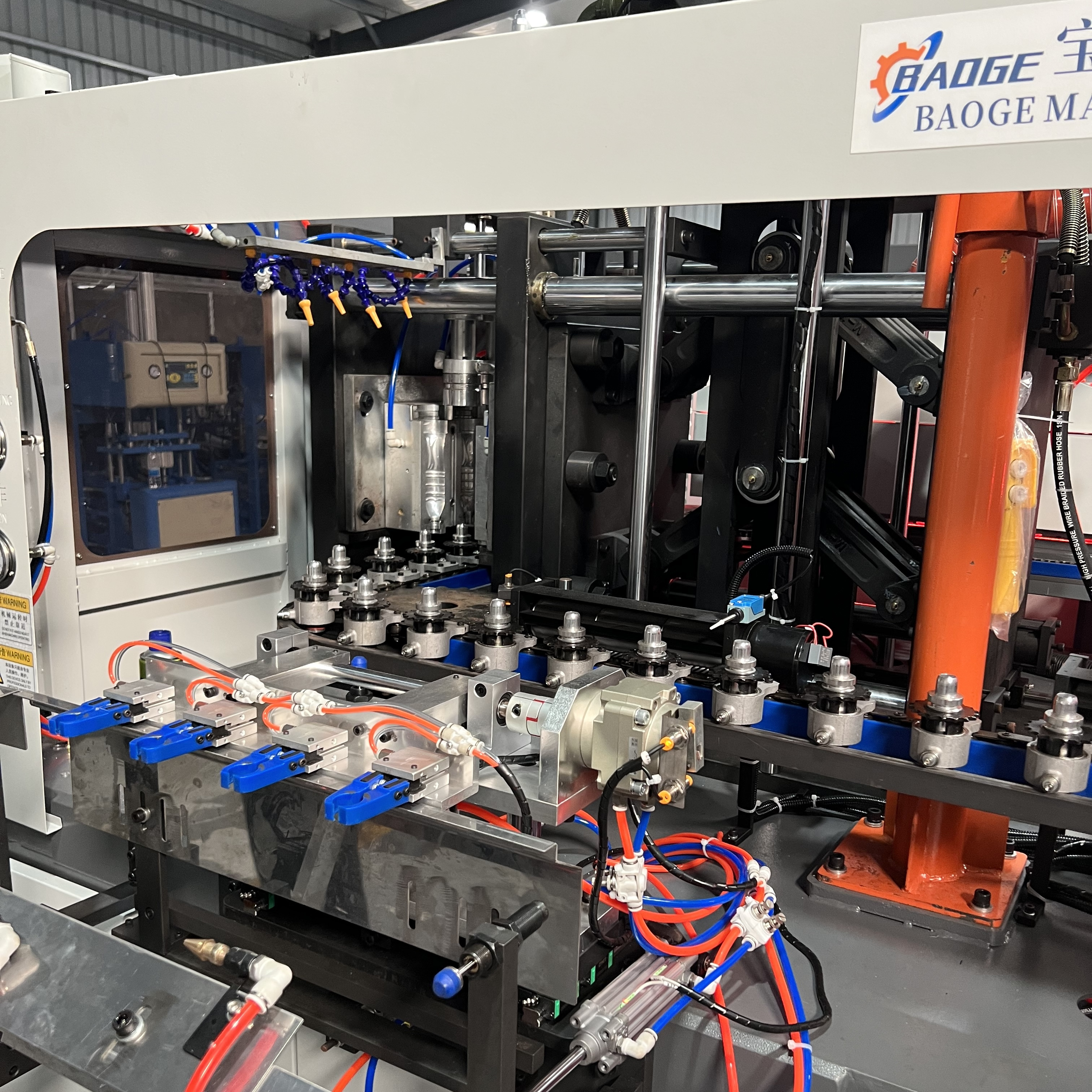

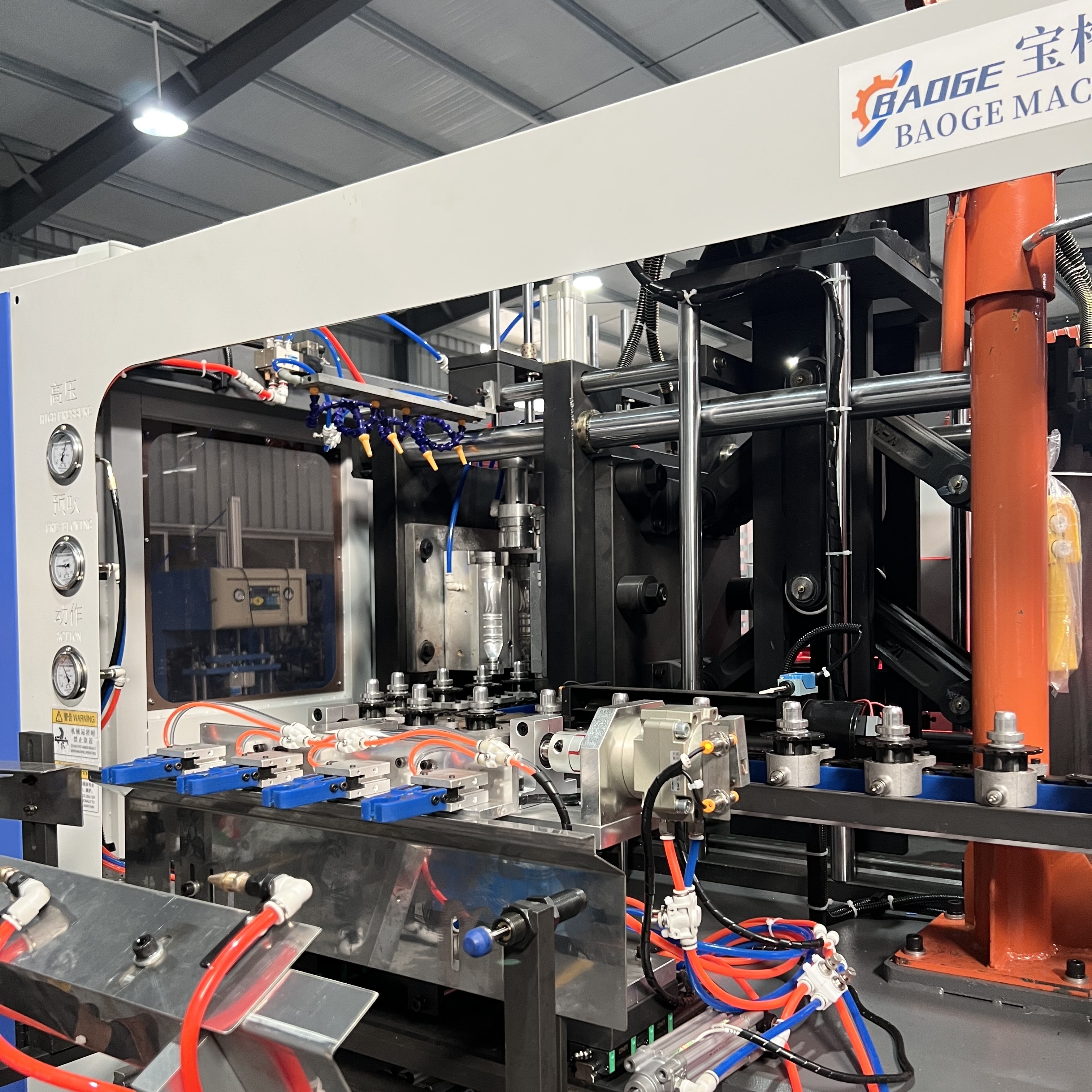

Details Images

1.1 New Auto Preform Unscrambler System.

*Adopts one-way preform-feeding structure and preform-separating by servo motor structure which solve the preform block and abrasion problem.

*There are two photoelectric sensors to control preform-loading motor and preform-separating cylinder that will warn the operator to add the preforms into the hopper when lacks preform instead of stopping the machine.

1.2 New Heating System.

*Perfect heating system design decrease power consumption.

*Special oven design helps power saving and easy maintain.

*Each lamp position and temperature can be adjusted.

*Cycle air-cooling system keeps the oven temperature constantly.

1.3 The Application Of Servo System On Main Transmission.

The transmission adopts servomotor for positioning that can orientate the preform-heating base quickly, accurately and steadilywhen the machine starts and running.

1.4 Servo Technology Innovation On Clamping System & Stretching.

*Adopts servo motor to drive the two cranks to control the clamping system which can shorten the mold-clamping time and improveproductivity, and also solve the swelling mold and big joint line problem with the effect of pressurize plate.

* Servo motor using for stretching to ensure the bottle blowing speed faster and more stable bottle quality.

1.5 Easy To Change Bottle Shape.

*Drawer type mold structure design is easy for mold changing. Within one hour can change a mold on the condition of same bottleneck diameter.

1.6 Intelligent Human-Machine Interface.

*Human-machine interface control, easy operate and monitor.

*Live production information supervise, auto record production data everyday.

*Failure warning and troubleshooting.

Taizhou Baoge Service

Bottle Design.

Our designers can design bottle styles according to your requirements.

Machine Layout.

We will confirm the machine layout according to your factory.

Sample Project.

We can provide a sample project for you to visit.

Complete device connection drawing

Hot Products

Hot Searches