- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

500-033-5

-

Place of Origin:

-

Taiwan, China

-

Brand Name:

-

FASTFIX-IT

-

Model Number:

-

903-240

-

Type:

-

Epoxy adhesive

-

Material:

-

Pure epoxy

-

Ratio:

-

1:1

-

Volume:

-

24 ml

-

Finish color:

-

Light Amber

-

Shelf life:

-

24 months

-

Working time:

-

5--7 min. ( 28 gm @ 72℉ )

-

Fixture time:

-

10-15 min. @ 72 ℉

-

Functional cure:

-

3/4- 1 hr. @ 72 ℉

-

Full curing time:

-

12 hours

-

Hardness Shore D:

-

85

Quick Details

-

CAS No.:

-

Mixture

-

Other Names:

-

Lquid Epoxy

-

MF:

-

Mixture

-

EINECS No.:

-

500-033-5

-

Place of Origin:

-

Taiwan, China

-

Brand Name:

-

FASTFIX-IT

-

Model Number:

-

903-240

-

Type:

-

Epoxy adhesive

-

Material:

-

Pure epoxy

-

Ratio:

-

1:1

-

Volume:

-

24 ml

-

Finish color:

-

Light Amber

-

Shelf life:

-

24 months

-

Working time:

-

5--7 min. ( 28 gm @ 72℉ )

-

Fixture time:

-

10-15 min. @ 72 ℉

-

Functional cure:

-

3/4- 1 hr. @ 72 ℉

-

Full curing time:

-

12 hours

-

Hardness Shore D:

-

85

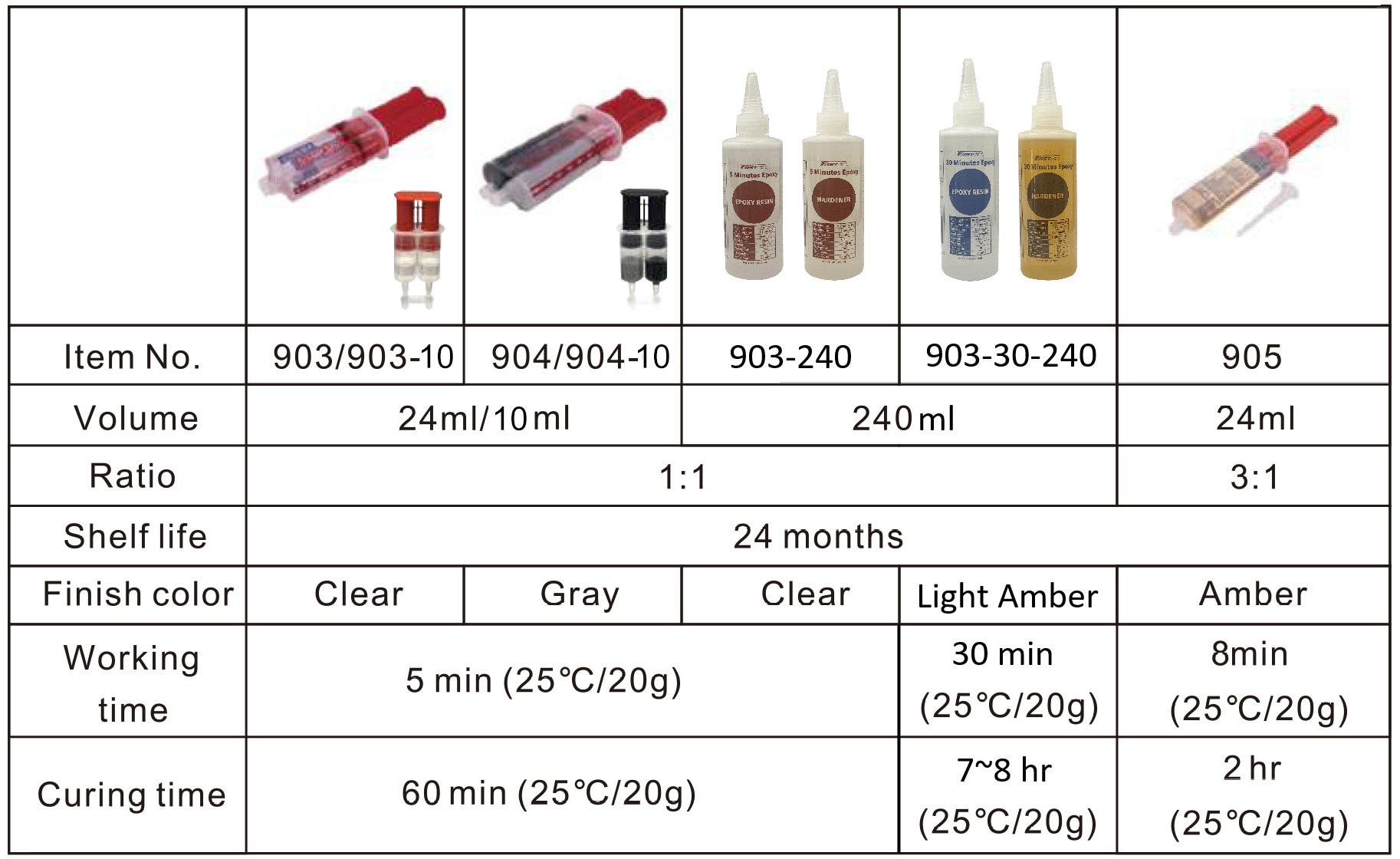

Production Name: Clear Liquid Epoxy Syringe

Product Code: 903-240

Product Description:

Epoxy syringes is epoxy liquid adhesive used to bond wood, metal, glass, ceramic, concrete, fabric, and remains clear from application through full cure to help blend in with material. It forms a tough bond that is flexible for durability.

Application of:

Steel epoxy adhesive liquid bonds wood, metal, glass, ceramic, concrete, and fabric.

Features:

1. Clear epoxy adhesive liquid bonds wood, metal, glass, ceramic, concrete, and fabric.

2. Continuous service temperature range from -20 to +300 degrees F (-29 to +150 degrees C)

3. Provides work time of approximately 5 minutes, cure time for function of 1 hour, and full cure time of 12 hours.

4. Forms tough bond for durability.

Product Details:

How to Use:

1. To cut the syringe tip.

2. To squeeze & mix the required amount, and then apply to repair surface within 2 minutes.

3. To cover the open tip with plastic plug (attach on the pusher).

Where to Use:

|

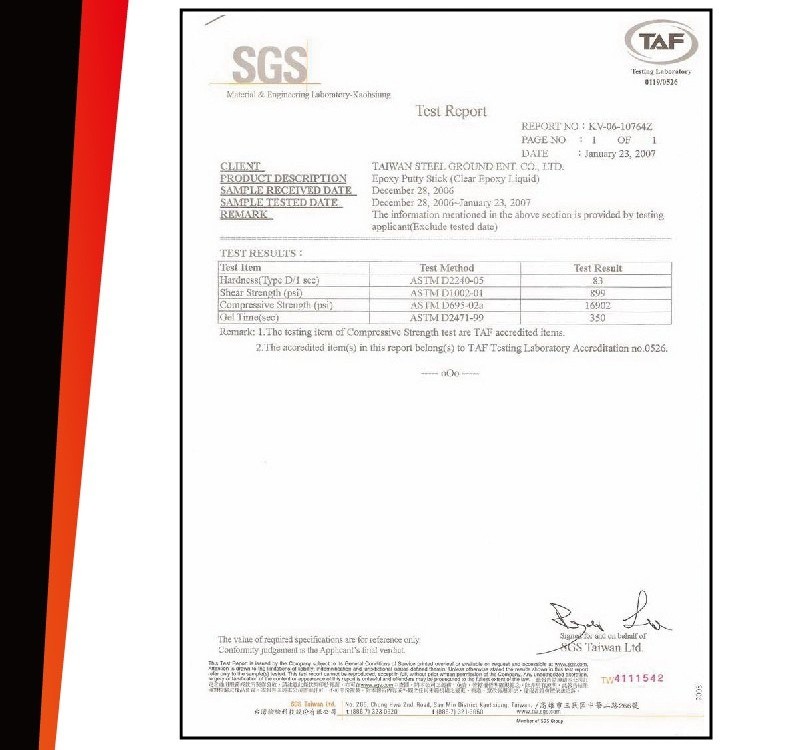

TYPICAL PHYSICAL PROPERTISE

|

RESULTS

|

TEST METHOD

|

|

|

Cure 7 days@75℉

|

|

Adhesive Tensile Shear ASTM D 1002

Dielectric Strength, volts/mil ASTM D 149 Cure Hardness Shore D ASTM D 2240 |

|

|

T-peel

|

2-3 pli

|

|

|

|

Impact Resistance

|

5.5 ft.lb./in.(2)

|

|

|

|

Tensile Elongation

|

1%

|

|

|

|

Shore Hardness

|

82 Share D

|

|

|

|

Gap-Fill

|

Good

|

|

|

|

Dielectric Strength

|

490 volts/mils

|

|

|

|

% Solids by Volume

|

100

|

|

|

|

Adhesive Tensile Lap Shear(GBS)

|

1900 psi @ 0.005" bond line

|

|

|

|

Specific Volume

|

25.1 in(3)/lb

|

|

|

|

Uncured

|

|

|

|

|

Color

|

Metal

|

|

|

|

Mixed Viscosity

|

10000 cps

|

|

|

|

Mix Ratio By Volume

|

1:1

|

|

|

|

Mix Ratio By Weight

|

1:1

|

|

|

|

Mixed Density

|

9.17 lbs/gal.: 1.10 gm/cc

|

|

|

|

Working Time

|

5-7 min. ( 28 gm @ 72℉ )

|

|

|

|

Fixture Time

|

10-15 min. @ 72 ℉

|

|

|

|

Functional Cure

|

3/4- 1 hr. @ 72 ℉

|

|

|

|

Full Cure

|

12

|

|

|

|

Service Temperature

|

Dry, - 40℉ to 200℉

|

|

|

Packaging:

|

Item#

|

903 (clear)

|

904 (steel)

|

|

|

Volume

|

24 ml (12+12)

|

|

|

|

Box Q'ty (with blister card)

|

12 pcs / box; 96 boxes / CNT

|

|

|

|

Box Q'ty (without blister card)

|

20 pcs / box; 10 boxes / CNT

|

|

|

Shipping:

By sea/ air/ courier. (FOB Kaohsiung)

Courier includes DHL, FedEx, TNT, EMS, etc.