- Product Details

- {{item.text}}

Quick Details

-

Effective Volume:

-

5-10CMB

-

Dimension(L*W*H):

-

15*10*4m

-

Voltage:

-

380V/400/415/480V

-

Power:

-

20-30KW

-

Weight (KG):

-

16000

-

Keyword 1:

-

actived carbon machine

-

Name:

-

carbonization furnace

-

Keyword 2:

-

actived carbon making machine

-

Application:

-

Sawdust/Rice Husk/Palm husk/Rice Husk/Coconut Husk/Biomass Wastes

-

Capacity:

-

300-1200KG/H

-

Pre-heating fuel:

-

Coal Gas/LPG/natural gas/Diesel

-

Type:

-

Continuous Charcoal Making Machine

-

Function:

-

Make Carbonization

-

Main machine:

-

Charcoal Making Kiln

-

Certification:

-

ISO9001

Quick Details

-

Place of Origin:

-

Henan, China

-

Marketing Type:

-

Hot Product 2023

-

Brand Name:

-

FTL Machinery

-

Effective Volume:

-

5-10CMB

-

Dimension(L*W*H):

-

15*10*4m

-

Voltage:

-

380V/400/415/480V

-

Power:

-

20-30KW

-

Weight (KG):

-

16000

-

Keyword 1:

-

actived carbon machine

-

Name:

-

carbonization furnace

-

Keyword 2:

-

actived carbon making machine

-

Application:

-

Sawdust/Rice Husk/Palm husk/Rice Husk/Coconut Husk/Biomass Wastes

-

Capacity:

-

300-1200KG/H

-

Pre-heating fuel:

-

Coal Gas/LPG/natural gas/Diesel

-

Type:

-

Continuous Charcoal Making Machine

-

Function:

-

Make Carbonization

-

Main machine:

-

Charcoal Making Kiln

-

Certification:

-

ISO9001

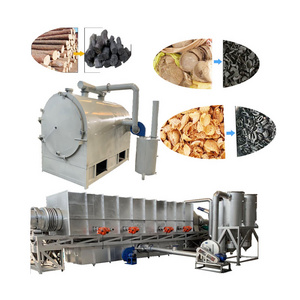

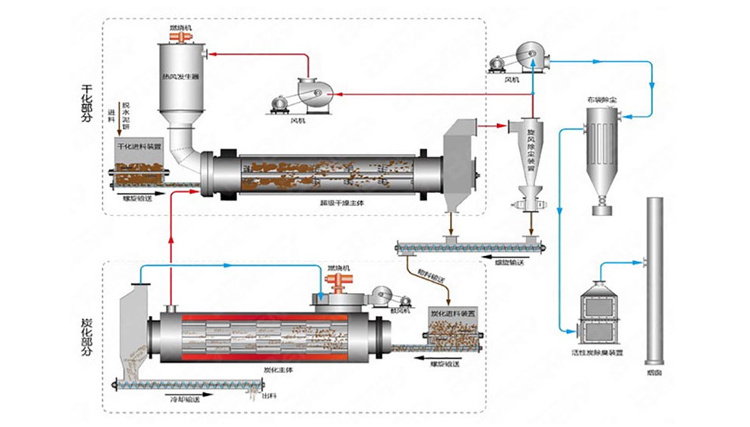

Carbonization kiln Furnace Activated Carbon Making Machine

plant/production line

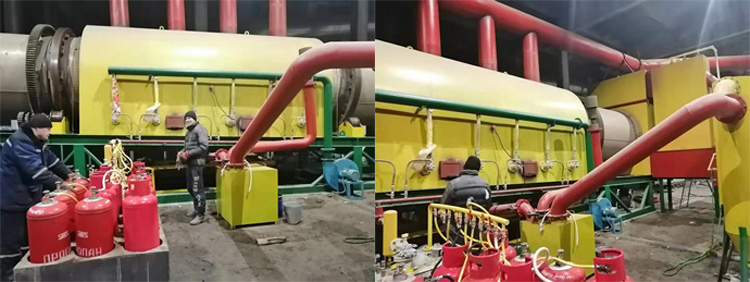

1. Carbonization kiln Furnace

FTL Machiery produce

Rotary carbonization furnace machine. It is also called Continuous charcoal making machine can turn the raw material (sawdust ,rice hull ,weeds and shells ,straw ,) into charcoal . When the moisture content of raw material is more than 15%, raw materials need a dryer to dry. It is selling well for its easy operating, high capacity, good quality.

>>> This furnace is ideal equipment for wood briquettes to have anoxic distillation carbonization.

Available raw materials: coconut shell, fruit wood, peach shell, apricot shell, coal, etc

Burning the raw material inside of the gasification furnace (as sawdust, shell, Palm shell, husk, straw, wood scrap etc.), the produced flue gas in pipeline within after spray pour, cooling purification, became combustible gas (carbon monoxide, methane, ethane,), as early carbonization of heat, heating and carbonizing the raw material inside of the carbonization furnace(as mechanism core rod, abandoned logs, bark, coconut shell, life garbage,etc.)

When the temperature reached to 300 degrees Celsius, carbonization furnace starting carbonizing of raw materials, producing smoke; flue gas become into a combustible gas after spray pour, cooling purification by the cooling purification system, continue carbonizing, then gasifier stop working.

|

Model

parameter |

(m) |

(Kw) |

Yield(t/day) | Outline size(mm) |

|

Rotary carbonization furnace

(external heat type) |

Φ1.2m×15m | 18.5 | 8 | 15000*1500*4000 |

| Φ1.5m×15m | 25 | 10 | 18000*1500*4000 |

Features of FTL Carbonization kiln Furnace :

1)easy operation,simple maintenance

(2)environmental protection:smokeless;combustible gas can be recycled.

(3)energy-saving

(4)capacity is a breakthrough:1000 kg/h,you can make charcoal 24 hours per day

(5)It can greatly increased carbonizing ratio (increased from about 88% to 99%)

(6) Fully continuous, large capacity .

(7) Free installation for clients.

(8) 3 years warranty

(9) Localization service

Other services from June, FTL Machinery:

3. Mineral ore benefication Plant