- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

subject to the customer

-

Power:

-

subject ot the demension

-

Dimension(L*W*H):

-

subject to the demension

-

Weight:

-

15000 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

fuction:

-

Waste Plastic oil Recycling

-

skill:

-

catalyst diatilled,airtight mixing heating

-

characteristics:

-

low cost,convenient,noiseless,environmental

-

heat method:

-

fuel oil,gas

-

max tempreature:

-

410

Quick Details

-

Flow:

-

from 1 ton to 30 ton every day

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

Junneng JNC

-

Voltage:

-

subject to the customer

-

Power:

-

subject ot the demension

-

Dimension(L*W*H):

-

subject to the demension

-

Weight:

-

15000 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

fuction:

-

Waste Plastic oil Recycling

-

skill:

-

catalyst diatilled,airtight mixing heating

-

characteristics:

-

low cost,convenient,noiseless,environmental

-

heat method:

-

fuel oil,gas

-

max tempreature:

-

410

Waste Plastic oil Recycling To Diesel Oil Machine With 5 years guarantee

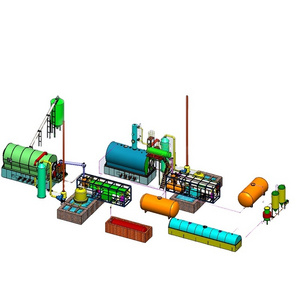

overview

This Waste Plastic oil Recycling To Diesel Oil Machine With 5 years guarantee can be used in black engine oil,Crude oil , plastic oil and shale oil, to get gasoline and diesel oil through distilled catalyst. Pumping into the heater with Waste oil , through the coal (or fuel oil)

heating to working temperature, the maximum working temperature about 410 degree and the

required gasoline and diesel oil can be obtain ed after catalytic distillation. When the reaction of

waste oil in reactor is complete, stop heating, and remove residue from the tank of bottom, then this

machine can be used again.

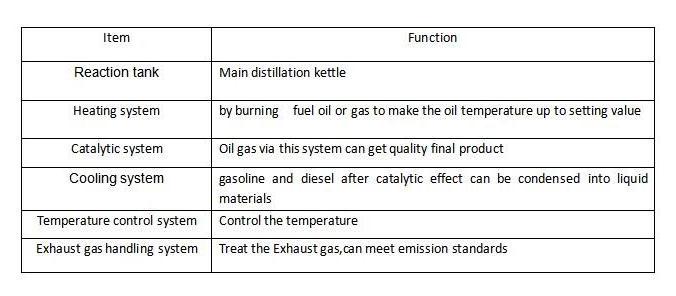

2, Systems of equipment

3 ,Index of oil after treatment:

diesel oil : 8 6-88 % , gasoline oil: 5-6 % ,oil residue: 6-8%.

Low-speed diesel engine can be used directly.

performance characteristics , advantage introduction

1 Working principle: waste oil under the action of catalyst distillation to get high quality diesel

2 Do not need acid,alkali,clay to refine the final diesel, just use our plate frame filter machine to remove the impurities.

3 InDirect heating with fuel or gas, convenience, economy, health, safety, environmental protection

4 The total cost of processing one ton used oil only USD22(including fuel, electricity and catalyst cost)

5 High oil yield: diesel 86~88%,gasoline 5~6%,oil residue 6~8%

6 This machine use a special way heating,high thermal efficiency, and difficult to form carbon fouling, greatly reducing consumable and maintenance costs.

7 Currently in the market, the distillation is based on the coil heating, the temperature can’t meet the technical requirements, oil yield only 65%. This kind of heating mode can make it easy to scale.what’s more, it needs high temperature pump, which is expensive, easily breakable, need frequent replacement, high cost in the later period

8 This Waste Plastic oil Recycling To Diesel Oil Machine With 5 years guarantee is safe, reliable, durable, easy operation, low labor intensity, 1 to 2 workers can easily operate the machine.

1 what kind of raw material the JNC machine can treat

JNC machine can treat all kinds of waste engine oil,plastic oil and crude oil

2 what kind of final product we can get

main product is diesel,a little gasoline and oil residue

3 how about the oil yield

in normal industrial production,can get at least 85% diesel.this can be assured

4 how to heat the Waste Plastic oil Recycling To Diesel Oil Machine With 5 years guarantee

can use fuel oil or gas to heat,environmental friendly,don't suggest use coal.not good for environment

5 need any other special chemical in the process

just need our ond kind catalyst,don't need other chemical.don't need acid and clay

6 what kind of equipment need customer prepare?

customer just prepare the good oil and waste oil tanks,a water pool and power supply

7 how to install the JNC machine

engineer will at site for installaton and commissioning,till customer can use smoothly

8 how about the guarantee

5Year Guarantee for main parts,1 Year for

mechanical

and

electrical

products.

any question of the plant will reply in 24 hours!

9 need how many workers to operate the machine,need any special technologist?

2 workers can easily operte the plant,don't need special technologist

10 about how long can deliver the machine

according to different capacity,usually 30~50 working days can deliver the machine