- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 50Hz

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Reliable

-

Dimension(L*W*H):

-

1900*1420*2000mm

-

Weight:

-

2000KG

-

Function:

-

Washing Filling Capping

-

Usage:

-

Beverage Packaging

-

Filling material:

-

Flowing Liquid

-

Bottle type:

-

PET Plastic Bottle

-

Material:

-

SUS304/316

-

Capacity:

-

2000bph

-

Name:

-

Hot Sales Pure / Mineral Water Filling / Bottling Machine

-

Control:

-

PLC+ Touch Screen

-

Certification:

-

CE ISO

Quick Details

-

Machinery Capacity:

-

2000BPH

-

Packaging Material:

-

Glass, Metal, Paper, Plastic, Wood

-

Filling Material:

-

Water

-

Voltage:

-

380V 50Hz

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Reliable

-

Dimension(L*W*H):

-

1900*1420*2000mm

-

Weight:

-

2000KG

-

Function:

-

Washing Filling Capping

-

Usage:

-

Beverage Packaging

-

Filling material:

-

Flowing Liquid

-

Bottle type:

-

PET Plastic Bottle

-

Material:

-

SUS304/316

-

Capacity:

-

2000bph

-

Name:

-

Hot Sales Pure / Mineral Water Filling / Bottling Machine

-

Control:

-

PLC+ Touch Screen

-

Certification:

-

CE ISO

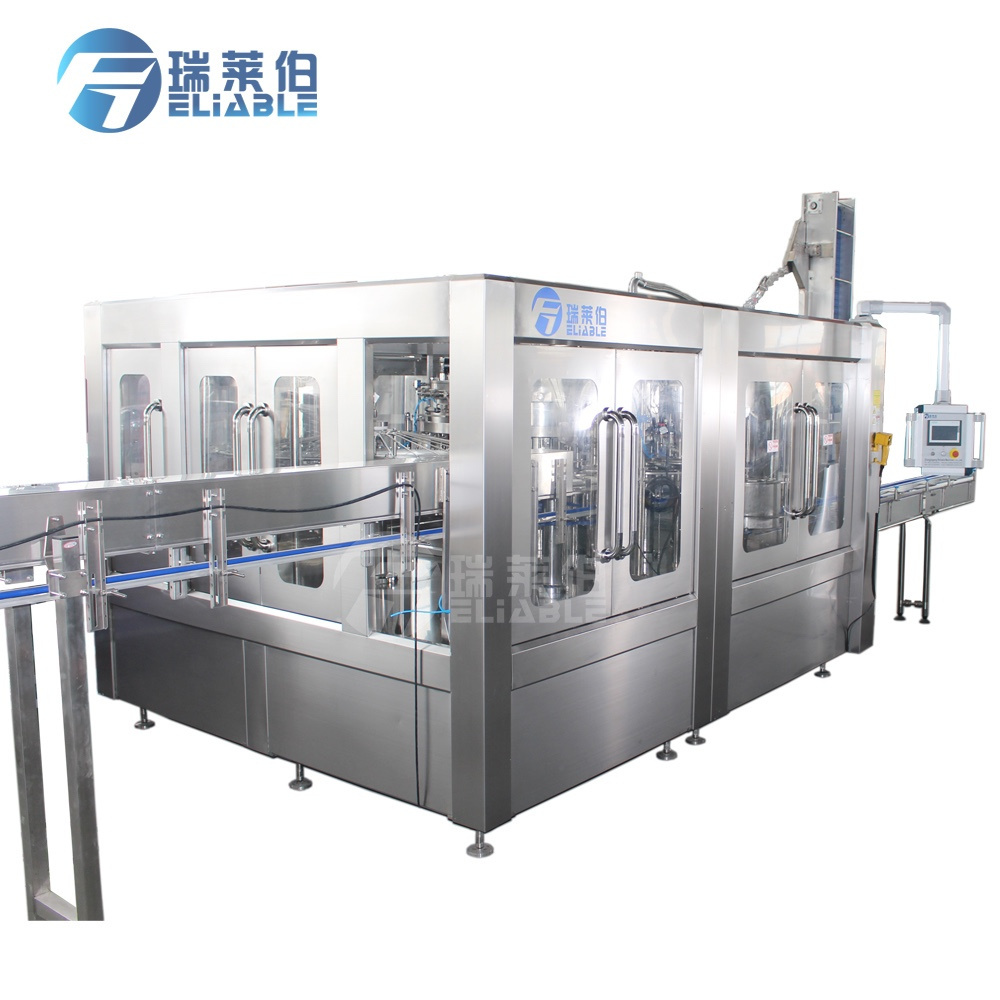

RELIABLE Brand Hot Sales Pure / Mineral Water Filling / Bottling Machine

1. This series of machines are mainly used for the Non-Aerated drink such as mineral water, pure water, non-gas wine drink and so on, with optional capacity from 2,000 to 18,000BPH. The machine design is shorten the time for the drink material contact with outside, Increased the sanitation condition and throughout and economy benefit.

2. This drinking water filling equipment adopts bottle neck holding transmission technology to realize fully automatic rinsing, filling and capping. Most elements of the electrical system employ famous brand advanced products. Each machine element that contacts with the liquid is made of high quality stainless steel. They obtain the advantages of good abrasive resistance, high stability, low failure rate, etc. The quality of the equipments reaches the international level.

3. The rinsing, filling and capping will be finished just by one machine. It is very convenient to change bottle size by means of advanced bottle conveying technology--bottleneck clamping & bottle suspending technology.

4. Advanced programmable PLC is equipped to control the main machine. Main electronic components are all from famous international enterprises. All spare parts that may touch with water are made from high-quality SUS304 stainless steel.

The bottle is blew into the bottle shifting wheel, when the flushing clamp reaches the bottle neck, the jaw will clamp the bottleneck, under the guidance of the rail, the clamp will turn the bottle 180°into an upright position, through second bottle pusher into the filling position.(the whole machine contains 14~40 sets of clamps ).

The filling part is manly composed of a filling valve and filling transmission parts. The washed bottle reaches the filling position via the bottle shifting wheel. In the mean time, the bottle clamping plate of the filling machine will clamp the bottle and move up to seal the bottle, filling valve will open, send the liquid into the bottle. When the liquid level of the bottle reaches the trachea of the filling valve, the filling will stop.

The capping part consists of 5~12 sets of screw head, capping transmission part, a sorting part and an under cover tube parts. The bottle which has finished filling will enter the capping position via the driving wheel. The photoelectric detection of the detecting signal detects the bottle, send a message to the valve cover, the cylinder cap will open, the caps will be blew into the cover plate by compressed air.

Air conveyor (Free of charge)

1/Air conveyor is fixed on the floor, with fan installed on the top.

2/Air filter is positioned at every entrance of air fan, to prevent dust blown into bottles.

3/Bottles are held on the neck in the conveyor and transported into filling machine by blowing power.

Flat conveyor (Free of charge)

1/Energy saving. High efficient. Adapt to customer factory layout

2/Special lubrication system, keep products clean, health, safety

3/Extended service life

4/Electric eyes design keep whole line running safety and quickly

RELIABLE Brand Hot Sales Pure / Mineral Water Filling / Bottling Machine

|

Model

|

CGF8-8-3

|

CGF12-12-6

|

CGF18-18-6

|

CGF24-24-8

|

CGF32-32-10

|

CGF40-40-12

|

|||||

|

Washing No

|

8

|

12

|

18

|

24

|

32

|

40

|

|||||

|

Filling No

|

8

|

12

|

18

|

24

|

32

|

40

|

|||||

|

Capping No

|

3

|

6

|

6

|

8

|

10

|

12

|

|||||

|

Capacity(500ml)BPH

|

2000

|

4000

|

6000-8000

|

10000-12000

|

12000-15000

|

15000-18000

|

|||||

|

Power(KW)

|

2

|

3.5

|

4

|

4.8

|

7.6

|

8.3

|

|||||

|

User Ambient Conditions

|

Temperature:10~40℃;Humidity:No dew

|

|

|

|

|

|

|||||

|

User Electrical Supply Specification

|

Voltage:220V,380V,3phase;Frequency:50HZ/60HZ or your requirement

|

|

|

|

|

|

|||||

|

Polyester bottle standard(mm)

|

bottle diameter φ50-110 ; bottle height 150-340mm

|

|

|

|

|

|

|||||

|

Suitable cap shape

|

Plastic screw cap

|

|

|

|

|

|

|||||

Zhangjiagang RELIABLE Machinery Co. Sells Main Products

2.Bottle blowing machine (Semi-automatic/Automatic)

3.Water treatment system (Pure Water/ Mineral Water)

4.Filling machine (Water/Juice/Carbonated Drinks/Yogurt/Tea/Milk/Bag/Cup and so on.)

5.Labeling machine (Shrinks Sleeve Labeling Machine/Adhesive Stick Labeling Machine/OPP Hot Melt Labeling Machine)

6.Date printer (Ink jet Printer/Laser Date Printer)

7.PE packing machine (PE Film Shrink Sleeve Package Machine/Carton Package Machine/Half-tray Shrink Wrapping Machine)