- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

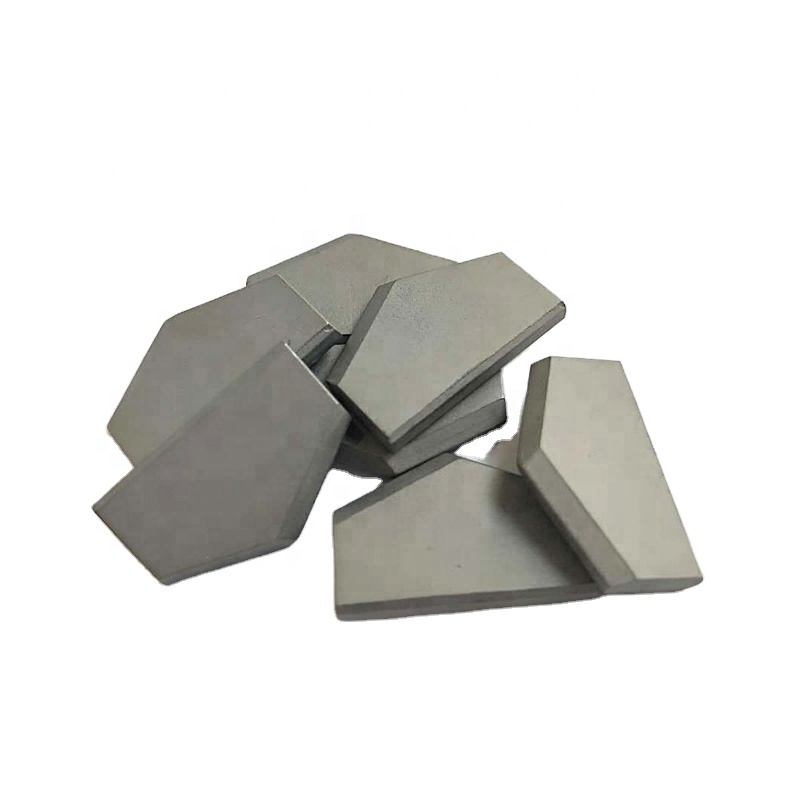

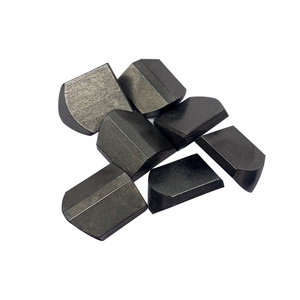

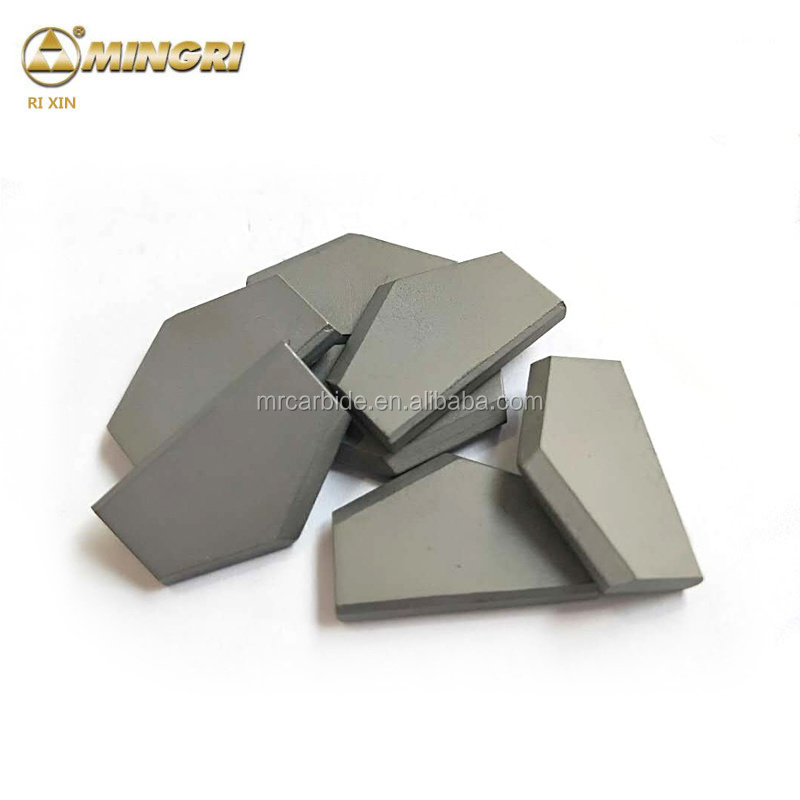

carbide electric hammer drilling tips

-

Keyword:

-

carbide electric hammer drilling tips

-

Material:

-

100% Virgin Tungsten Carbide

-

Surface:

-

Polish/sand blasting

-

Grade:

-

YG6C/YG8C/YG11C

-

Certificate:

-

ISO 9001:2000

-

Color:

-

Silvery Grey

-

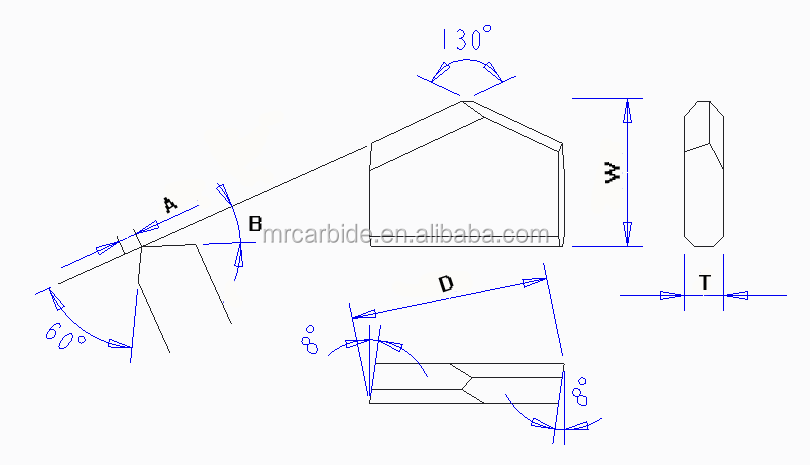

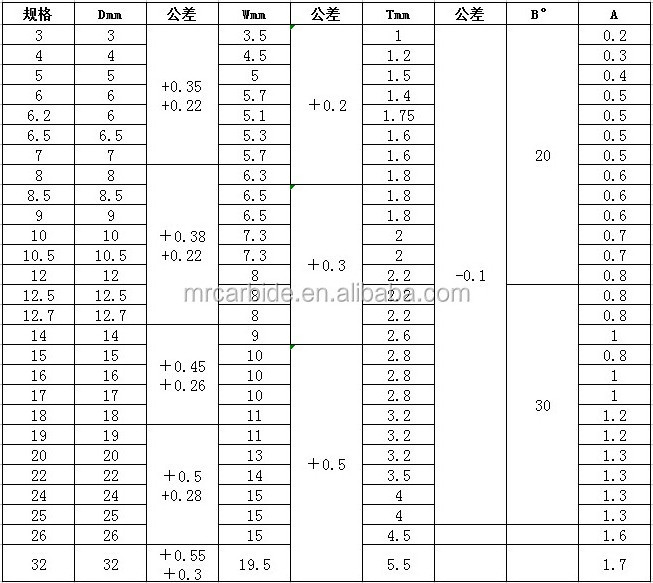

Size:

-

Cusomized

-

OEM:

-

Accepted

-

Advantage:

-

Manufactuer

Quick Details

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

Rixin

-

Model Number:

-

Customized

-

Product name:

-

carbide electric hammer drilling tips

-

Keyword:

-

carbide electric hammer drilling tips

-

Material:

-

100% Virgin Tungsten Carbide

-

Surface:

-

Polish/sand blasting

-

Grade:

-

YG6C/YG8C/YG11C

-

Certificate:

-

ISO 9001:2000

-

Color:

-

Silvery Grey

-

Size:

-

Cusomized

-

OEM:

-

Accepted

-

Advantage:

-

Manufactuer

Electric hammer percussion drilling tungsten carbide tips

1. Direct sale

2. High quality

3. Reasonable price

4. OEM available

5. Samples availble

Grade,properties and applications of carbide electric hammer drilling tips

|

Grade |

g/cm3 |

TRS |

Hardness |

Performance & application recommended |

|

MPa |

HRA |

|||

|

YG4C |

15.1 |

1800 |

90 |

Mainly used as small buttons for percussion bits to cut soft and medium hard formations. |

|

YG6 |

14.95 |

1900 |

90.5 |

For coring crowns, electric coal drill bits, coal cutting picks, oil cone bits and scraping knife bits, used in geological prospecting, coal mining and oil well boring. |

|

YG8 |

14.8 |

2200 |

89.5 |

For coring crowns, electric coal drill bits, coal cutting picks, oil cone bits and scraping knife bits, used in geological prospecting, coal mining and oil well boring. |

|

YK05 |

14.95 |

2500 |

90.5 |

Mostly used as the buttons of small and medium sized percussion bits and as the inserts of rotary prospecting bits to cut soft and medium hard formations. |

|

YK15 |

14.6 |

2450 |

87.6 |

Suitable to strips, conical buttons for rotary percussion-resistant, geological prospection buttons, cut soft and medium hard formations. |

|

YK20 |

14.4 |

2500 |

86.8 |

Primarily for the buttons and inserts of rotary percussion bits to cut medium-hard and hard formations. |

|

YK25 |

14.4 |

2550 |

87.2 |

Primarily for the buttons and inserts of rotary percussion bits to cut medium-hard and very hard formations. |

|

YG11C |

14.4 |

2700 |

86.5 |

Largely for the inserts and buttons of percussion bits and tricone bits to cut medium-hard, hard, and very hard formations. |

|

YG13C |

14.2 |

2850 |

86 |

Primarily for the buttons of tricone bits and inserts of rotary percussion bits to cut hard and very hard formations. |

|

YG15C |

14 |

3000 |

85.5 |

For oil cone drill bits, for medium soft and medium-hard rocks. |

1, carbide electric hammer drilling tips are brazed on percussion drill or electric drill or pneumatic drill to drill wall, ground, mining ect.

2, widely used for electric drill in special condition, also used for electric dill or pneumatic drill for building,geology and coal mining

3, carbide electric hammer drilling tips suitable for harder rock or rock with hard stratum or metallic rock

4, carbide electric hammer drilling tips suitable for all kinds of cement drill bits

1, Soon after the order is confirmed, carbide electric hammer drilling tips

products will start to prepare the RTP powder as per customer’s requirement with our wet-grinding machine

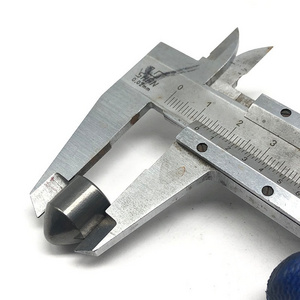

2, Before mass production, we need to do a trial pressing and sintering using every mould, and we check the appearances and the sizes of

carbide electric hammer drilling tips

samples with micrometer, projectors etc. to ensure that the requirements of the drawings can be met before batch production

3, Bulk production ,press the raw materials to shape blanks,and all carbide electric hammer drilling tips blanks must be passed by semi finished inspection,

4, Then sinter blanks to finish (HIP) and finished products inspection, we have 10 sets of vacuum sintering furnace and 2 sets of HIP in the factory ensure the best quality and production capacity.

5, 1). cleaning/tumbling is to make the carbide electric hammer drilling tips look more beautiful.

2).The carbide electric hammer drilling tips can be ground according to customers’ order to a tolerance of +/-0.05

Generally we will take care of your machine packages well like picture show.

Firstly our worker will make sure your carbide electric hammer drilling tips clean before package.

Then add plastci foam into inner box for the whole carbide electric hammer drilling tips for sweet protection.

At last we will make export standard strong cartonn or plywood case package according to your needs.