- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Bathroom

-

Design Style:

-

Traditional

-

Place of Origin:

-

China

-

Brand Name:

-

Yuhong

-

Model Number:

-

JSA-101

-

Type:

-

waterproof coating, Other Waterproofing Materials

-

Shape:

-

liquid

-

Core Material:

-

N/A

-

Format:

-

N/A

-

Application Method:

-

Bursh

-

Certificates:

-

CE/ISO9001/ISO14001

-

Packing:

-

Pallet

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support, Onsite Training

-

Project Solution Capability:

-

Others

-

Application:

-

Bathroom

-

Design Style:

-

Traditional

-

Place of Origin:

-

China

-

Brand Name:

-

Yuhong

-

Model Number:

-

JSA-101

-

Type:

-

waterproof coating, Other Waterproofing Materials

-

Shape:

-

liquid

-

Core Material:

-

N/A

-

Format:

-

N/A

-

Application Method:

-

Bursh

-

Certificates:

-

CE/ISO9001/ISO14001

-

Packing:

-

Pallet

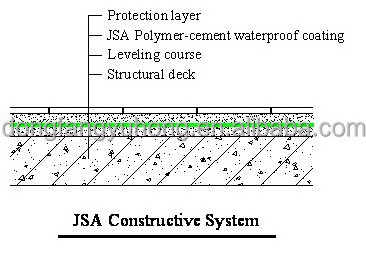

YUHONG Waterproof construction system

Products Description

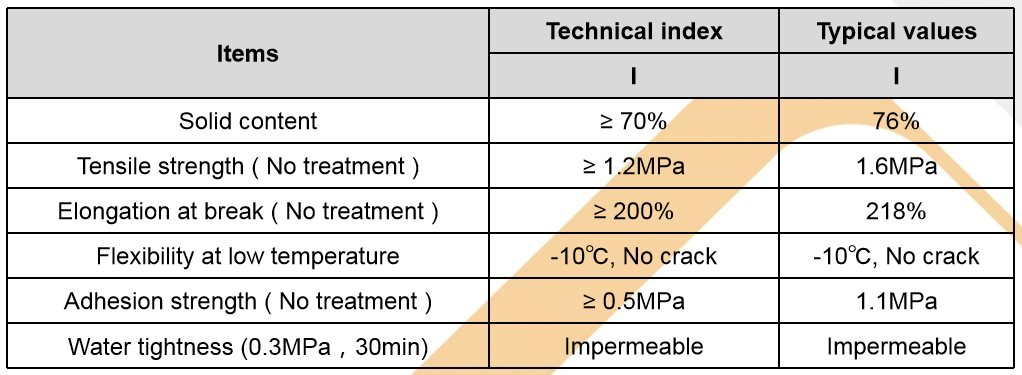

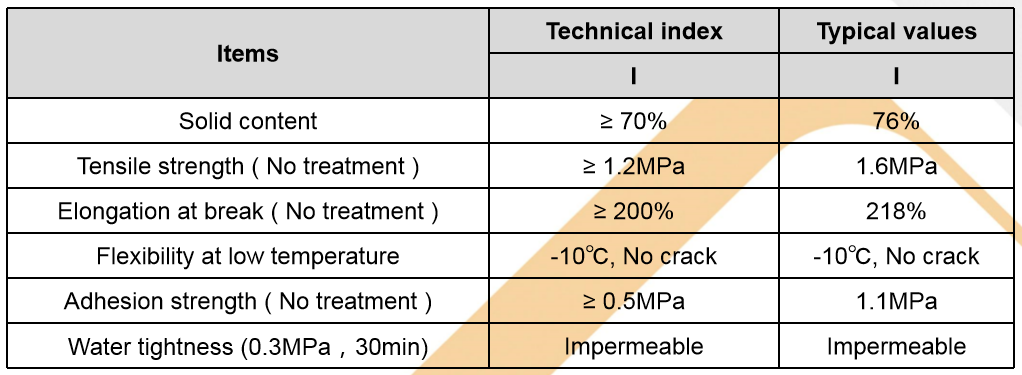

Polymer Cement Waterproof Coating

JSA-101 Polymer Cement Waterproof Coating is a two components water-base waterproof coating material which is made out of the organic liquid of high quality modified acrylic emulsion and various additives, together with the infinite powder of high-aluminum high-iron cement and the multiple additives, by scientific formulation.

Specifition

Product feature

• Flexibility: Flexible, accommodates movements in cracks, does not crack with aging.

• Adhesion: Provide excellent adhesion, damp substances constructability.

• Air breathable, but water resistant.

• Eco-friendly: Water based hence non-hazardous.

• Easy of application: Easy to apply by brush & roller.

Construction

Recommended dosage

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Construction Process

Surface Preparation→Additional layers of details→Waterproof layers of the entire area→Quality inspection & acceptance→Isolation layer

Construction Points

• Clean the surfaces thoroughly, ensure the surface to be coated is without water, oil, grease, dust, fungus and moss. Arc processing is used at pipe end, concave and convex corners.

• First place the liquid material and water into a bucket to mix, then add powder material into the bucket while being stirred mechanically and evenly. The mixed coating material should be fully used within 3 hours. Water is not allowed to be added in during using process.

• Additional layer must be made at the concave and convex corners, at pipe end and at water outlet. Pre-install reinforcement materials and then brush these places for 2-4 times until thoroughly penetrating into it. Keep no folds and edge warp.

•

For the entire area, first brush the vertical surface and then horizontal surface. Apply the second brush coat until the first brush layer completely dry up, and the brush direction should be vertical to the previous one. Each surface brush 2-3 times. Film thickness of the Plane should be more than 1.5mm,thickness of the vertical be more than 1.2mm.

• The drying time in wet environment should be extended. Carry out the closed-water test after the waterproof layer fully dried up. Apply the isolation layer construction according to design requirement when passing the acceptance inspection.

Packaging Transportation and Storage

Transportation & Storage

• Not flammable and explosive product, according to the general cargo transport.

• Stored in a cool and dry place under temperature of 5℃~35℃, when less than 5℃ take insulation measures.

• Keep away from the rain, direct sunlight and cold.

• Avoid collision and extrusion, packing is not damaged.

• Quality guarantee period is 12 months from date of manufacturing under normal storage and transportation conditions.

Hot Searches