- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

YUANDA

-

Voltage:

-

380V / Custom

-

Dimension(L*W*H):

-

Customized Size

-

Marketing Type:

-

150 pitch industrial conveyor

-

Weight (KG):

-

15000 kg

-

Product name:

-

Power and Free Hanging Overhead conveyor system

-

Feature:

-

Twin two double track, Non-synchronous asynchronous movement

-

Capacity:

-

50~5000kg per point

-

Control Method:

-

Automatic control box, manual load unload

-

Advantage:

-

High Efficiency Accumulation chain conveyor

-

Main electrical parts:

-

Schneider SEW

-

Power Source:

-

3 Phase 380V 50hz / Custmized

-

Travelling speed:

-

0~10m/min variable frequency adjustable

-

Keywords:

-

I beam C enclosed rail track Monorail conveyor system

Quick Details

-

Power:

-

2.2 KW

-

Warranty:

-

1 Year

-

Width or Diameter:

-

100mm

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

YUANDA

-

Voltage:

-

380V / Custom

-

Dimension(L*W*H):

-

Customized Size

-

Marketing Type:

-

150 pitch industrial conveyor

-

Weight (KG):

-

15000 kg

-

Product name:

-

Power and Free Hanging Overhead conveyor system

-

Feature:

-

Twin two double track, Non-synchronous asynchronous movement

-

Capacity:

-

50~5000kg per point

-

Control Method:

-

Automatic control box, manual load unload

-

Advantage:

-

High Efficiency Accumulation chain conveyor

-

Main electrical parts:

-

Schneider SEW

-

Power Source:

-

3 Phase 380V 50hz / Custmized

-

Travelling speed:

-

0~10m/min variable frequency adjustable

-

Keywords:

-

I beam C enclosed rail track Monorail conveyor system

Overhead manual single rail conveyor system overhead monorail I beam track variable speed conveyor for powder coating line

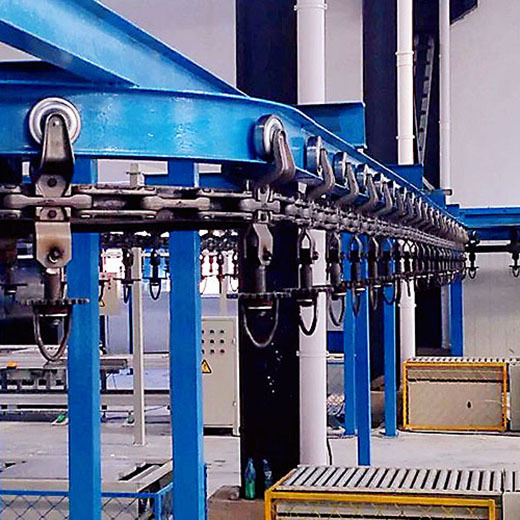

POWER AND FREE OVERHEAD CONVEYOR

Power and free overhead systems are flexible and easy to maintain. YUANDA’s range of power and Free Conveyors can handle loads from as light as 5 pounds per unit to 15 tons. Unlike basic continuously moving overhead monorail conveyor systems, power and free conveyors provide the unique ability to stop individual loads without stopping the entire production line.

Power & Free conveyors are based on a twin-track system. The top track is used for the power chain and the bottom free track for the carrier trolleys. On an equal pitch pusher dogs are fitted in the power chain and are used to pull the carriers around the system. The movable cams of the pusher dogs latch onto the trolley to form an interlink connection. A Power and Free conveyor can also be thought of as a train track system, with multiple trains moving independently. We refer to this as a non-synchronous conveyor.

Stop stations are used to disengage the link between the power chain and trolleys. When a stop station is closed the carrier will stop while the power chain keeps moving. Because of the pusher dog and trolley design multiple carriers can accumulate behind a stop station.

Advantages of the Power & Free Conveyor

Compact and save design with movable parts inside the track

Modular system with standard parts

Flexible design for optimal lay-out planning

Advanced automatic control system with touch screen user interface and remote access.

Overhead conveyor transports bulky or awkwardly shaped items that regular conveyor can't by suspending it below a powered chain track.

It can integrate several tracks with merges and diverts.

The track can execute sharp turns and elevation changes, which maximize use of facility space and allow high-density storage.

This conveyor can be run inverted with the load above the track if needed.

Variable chain speeds

Adaptability to changes in elevation

Pls contact us to get more information.

|

I TEM |

NO. |

ADVANTAGES |

|

OVERHEAD CONVEYOR SYSTEM |

1 |

Low noise |

|

2 |

Less power consumption |

|

|

3 |

Stable performance |

|

|

4 |

User-friendly and safe |

|

|

5 |

Make full use of space |

|

|

6 |

Large angle bending space |

|

|

7 |

High mechanization & automation |

|

|

8 |

Make any turns on both horizontal plane and vertical planes |