- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2190x2206x2300mm

-

Weight:

-

17000 KG

-

Marketing Type:

-

Hot Product 2021

-

Product name:

-

Suitable for Metallurgical Industry Jaw Rock Crusher

-

Keyword:

-

Stone Jaw Crusher

-

Max feeding size:

-

180mm

-

MOQ:

-

1 Set

-

Certification:

-

CE ISO

-

Color:

-

Customerized

-

Quality:

-

Advanced Technology

-

Installation:

-

Engineer Guide

-

Price:

-

Competetive (can Discuss

-

Key Word:

-

Jaw Crusher

Quick Details

-

Application:

-

Gold Mining

-

Capacity(t/h):

-

50-160t/h

-

Place of Origin:

-

Jiangxi, China

-

Dimension(L*W*H):

-

2190x2206x2300mm

-

Weight:

-

17000 KG

-

Marketing Type:

-

Hot Product 2021

-

Product name:

-

Suitable for Metallurgical Industry Jaw Rock Crusher

-

Keyword:

-

Stone Jaw Crusher

-

Max feeding size:

-

180mm

-

MOQ:

-

1 Set

-

Certification:

-

CE ISO

-

Color:

-

Customerized

-

Quality:

-

Advanced Technology

-

Installation:

-

Engineer Guide

-

Price:

-

Competetive (can Discuss

-

Key Word:

-

Jaw Crusher

Product Description

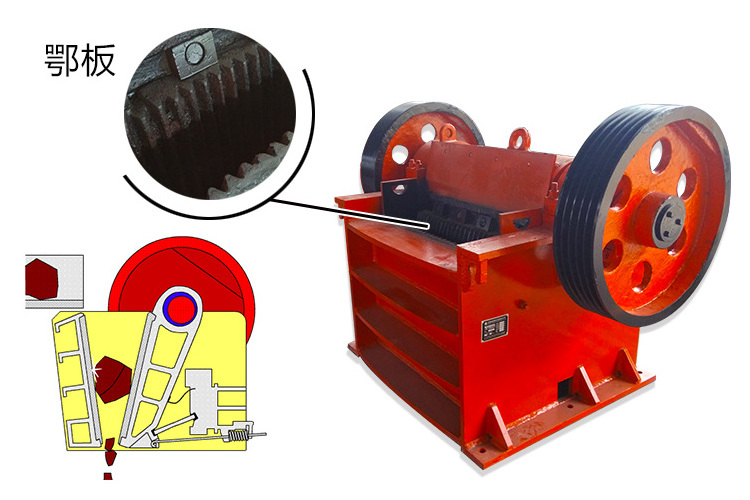

Jaw crusher is suitable for crushing a variety of soft and hard ores and rocks, whose largest compression resistance is under 320 MPa. Maximum size of to be fed materials must be less than what is required according to the maximum specification of technical parameters. Jaw crusher is mainly used for secondary and fine crushing of mid hardness ores and rocks in metallurgical industry, mining, chemistry, cement making industry, construction, refractory, pottery, porcelain industry, etc. All models of stone jaw crushers are available according to your different fineness requirements.

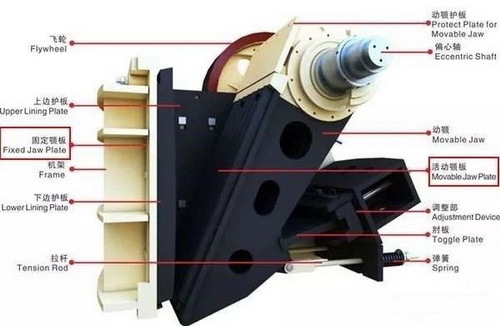

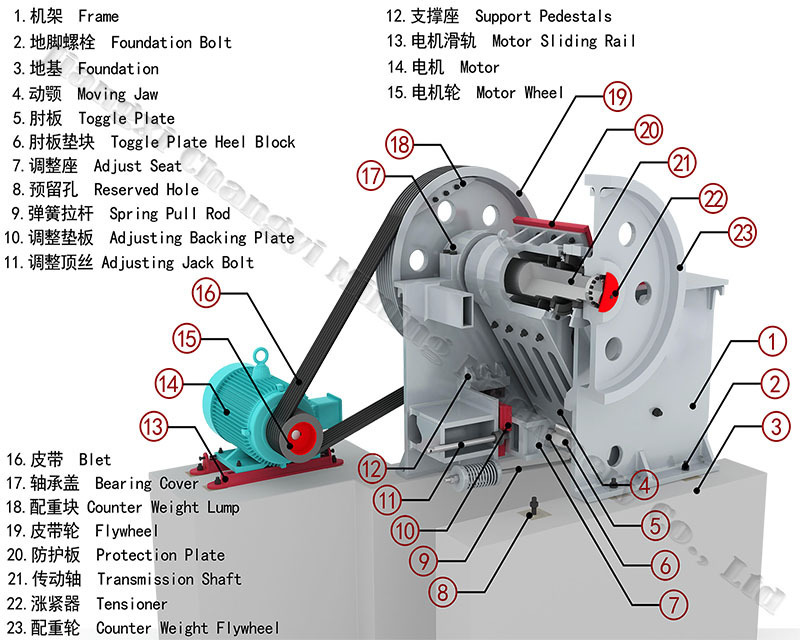

Working Principle

The working principle of the jaw crushers is very simple. Powered by a diesel or gas motor, the jaw crusher brakes materials in a crushing chamber. The materials are pushed inside the chamber from the top opening and when crushed they are released through the bottom opening.

Advantage

1 . Deep crushing cavity, no dead zone, increasing capacity and output of the feeding

2 . Large crushing ratio, uniform products particle size

3 . Pad-style nesting population adjustment devices, and ease of adjustment range

4 . Simple and reliable structure, low operation costs

5 . The discharging size of jaw crusher can be adjusted to meet the requirements of different users

6 . Low noise and less dust

7 . Be and drive by diesel engine if the working site is limited

Product Parameter

(Date only for reference,accronding to customer requirements for design and production.)

Application

Jaw crusher is mainly used for secondary and fine crushing of mid hardness ores and rocks in metallurgical industry, mining, chemistry, cement making industry, construction, refractory, pottery, porcelain industry, etc. All models of stone jaw crushers are available according to your different fineness requirements.

1. Jaw crusher is applied to fine crushing of various material of which compressive strength is less than or equal to 320Mpa. It is applied to Primary crushing stage of the rock stone crushing project.

2. The second stage we use impact crusher, cone crusher, hammer mil. For the

3. Last, vibrating screen is working for selecting the different size of the stone.

-----Maybe you are interested in-----

Spiral Chute Shaking Tabling Ball Mil

FAQ

Q: 1.What is your machine used for ?

A: This machine is used for separation the materials such as Gold, silver, platinum, tin, tungsten, lead, antimony, chrome,titanium etc.

Q: 2.Are you factory or trade company?

A: we are the Professional manufacturer from 2014.So we could give you original factory price than those trade companies. We're also warmly welcome your Visiting our factory if you are in China.

Q: 3.Can I operate it well, if I have no experience?

A: Do not worry! Our machines is designed to use easily.You are welcome to visit our company to be trained here,And we could arrange the engineer to go to your country/company to train your workers directly as your requested and the relative travel cost will be on your account.

Q: 4. Can you send me the video to show how the machine works?

A: Surely.we have made video of every machine,so if you need we can send for you to checking in clearly.

Q: 5. What should I take care when using the machine?

A: Please using the machine in regular and Keeping the machine away from thinner and other chemical liquid.

Q: 6.How about your Service ?

A: All of our machines have one year warranty and Whole-life Technology support to make sure your machine work well.

Q: 7.How long is your delivery time?

A: Generally it is 1-5 days if the goods are in stock. or it is 10-20 days if the goods are not in stock, it is according to quantity.

Our Services

We provide 12months quality warranty to make sure gravity machine well runs consistently.

Pre-sale services:

a. Professional engineer design the production line for you

b.Recommend suitable equipment according to your special demand.

During-sale services:

a.Pre-check and accept products before delivery

b.Send technicians to the jobsite for guiding the installation and adjustment

c.Training operators and finishing the check to satisfy your requiremnet

After-sale services:

a.Common problem can be solved through web in 24 hours,complex problem can be reacted immediately in 24 hours and solved as soon as possible

b.To establish long-term friendship, we will regulary contact with our customers.

Packaging and Shipping

|

Payment Terms of Shaker Table |

| • We usually accept T/T, L/C |

| • T/T: 30% of total amount as deposit, 70% balance before delivery. |

| • We will take pictures of finished products to you before delivery. |

| Way of Packing of Shaker Table |

| • FCL & LCL export standard container 20/40 feet. |

| • FCL: Sea-worthy package. Machines are fixed in container; spare parts are packed in wooden boxes. |

|

• LCL: Machines are packed in steel frame with plywood boxes. Customized package is available. |