- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

Plus or minus 1.5g

-

Packaging Type:

-

Cups

-

Voltage:

-

380V/220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Guocheng

-

Dimension(L*W*H):

-

7300MM*1000MM*2350MM

-

Weight:

-

3200 KG

-

Product name:

-

Filling Packaging Machine

-

Filling speed:

-

7000-9000 cups/h

-

Cup width range:

-

10-300MM

-

Material:

-

SUS304/316

-

Usage:

-

Yogurt

-

Filling head:

-

8 Heads

-

Frequency:

-

50Hz

-

Control:

-

PLC+Human Machine Interface

-

After Warranty Service:

-

Field maintenance and repair service

-

After-sales Service Provided:

-

Field installation, commissioning and training

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH

-

Packaging Material:

-

Plastic, Wood

-

Filling Material:

-

Milk, Water, Oil, Juice

-

Filling Accuracy:

-

Plus or minus 1.5g

-

Packaging Type:

-

Cups

-

Voltage:

-

380V/220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Guocheng

-

Dimension(L*W*H):

-

7300MM*1000MM*2350MM

-

Weight:

-

3200 KG

-

Product name:

-

Filling Packaging Machine

-

Filling speed:

-

7000-9000 cups/h

-

Cup width range:

-

10-300MM

-

Material:

-

SUS304/316

-

Usage:

-

Yogurt

-

Filling head:

-

8 Heads

-

Frequency:

-

50Hz

-

Control:

-

PLC+Human Machine Interface

-

After Warranty Service:

-

Field maintenance and repair service

-

After-sales Service Provided:

-

Field installation, commissioning and training

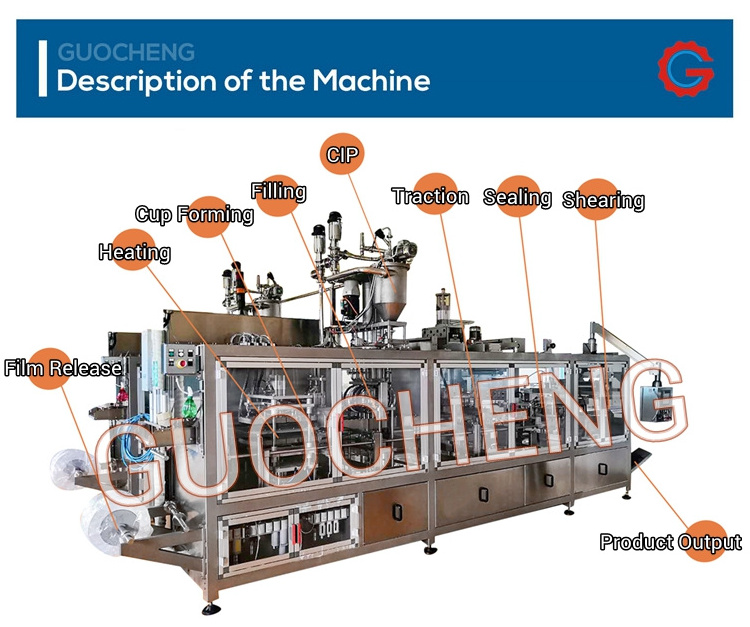

Fully Automatic Cup Forming Yogurt Filling Packaging Machine

CGF-LC Series cup forming filling sealing packaging machine is suitable for packaging of various beverages, yogurt, sauce, seasoning, water, etc. with the plastic sheet made of PET and PS etc.It can automatically accomplish the whole process of plastic cup forming, filling, sealing, cutting and product output.

| MODEL | FILLLING HEAD | PRODUCTION EFFICIENCY |

| CGF-LC-3 | 3 | 3000-14500 cups/h |

| CGF-LC-6 | 6 | 6000-7200 cups/h |

| CGF-LC-8 | 8 | 7000-9000 cups/h |

| CGF-LC-12 | 12 | 9000-12000 cups/h |

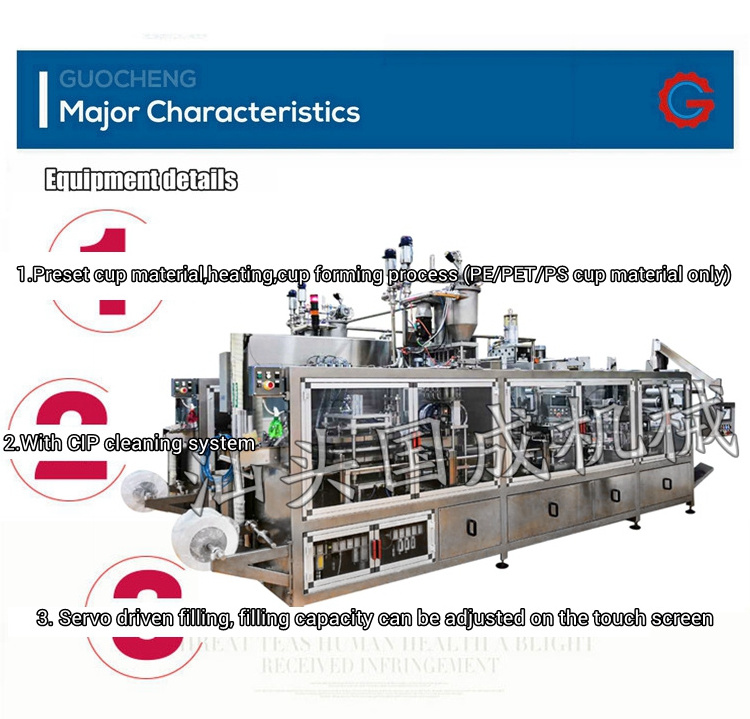

1. Preset cup material,heating,cup forming process (PE/PET/PS cup material only)

1. Preset cup material,heating,cup forming process (PE/PET/PS cup material only)

2.Integrated CIP device guarantees the pipes, valves, valve body and pistons which contact the material can be fully cleaned by rinsing, and are in accordance with hygienic standard.

3. Servo driven filling, filling capacity can be adjusted on the touch screen

Advantages:

a. The whole machine is fully automatic, including cup forming, filling, sealing, cutting and product output

b. The machine adopts International famous brand for parts,Japanese SMC,German Siemens,Festo,etc can be choosed.

c. This machine can realize cup heating and automatic cup forming. Various types of cups (PE / PET / PS material only) can be customized according to customer requirements

d. The whole machine is made of stainless steel 304.

e. Filling system with CIP device and servo driven, and the filling capacity can be adjusted on the touch screen.

f.The system adopts HMI control and intelligent control system.

g. Optional hot filling function for the filling system, which is applicable to the filling of viscous material.

h.With servo-driven filling, and the filling capacity can be adjusted on the touch screen

i. The forming and filling air is protected under positive pressure by the cleaned air from class 100 laminar flow system to improve the hygienic standard and shelf life of the product..