- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ACERETECH

-

Dimension(L*W*H):

-

12*3*2.5 m

-

Weight:

-

10000 KG

-

Name:

-

Twin Screw Extruder Machine

-

application:

-

compounding pelletizing machine

-

Fits for:

-

PET flakes, solid plastics, polymer compounding

-

Final product:

-

Pellets/granules

-

Cutting way:

-

Strand, Underwater

-

Melt filter:

-

Column/Piston, back-flush

-

PLC intelligent control system:

-

Schneider/Siemens

-

Lifting dryer:

-

Double

-

Machine test support:

-

Yes, with clients' materials

-

Screw:

-

Double-screw

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

38:1

-

Screw Speed (rpm):

-

600 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ACERETECH

-

Dimension(L*W*H):

-

12*3*2.5 m

-

Weight:

-

10000 KG

-

Name:

-

Twin Screw Extruder Machine

-

application:

-

compounding pelletizing machine

-

Fits for:

-

PET flakes, solid plastics, polymer compounding

-

Final product:

-

Pellets/granules

-

Cutting way:

-

Strand, Underwater

-

Melt filter:

-

Column/Piston, back-flush

-

PLC intelligent control system:

-

Schneider/Siemens

-

Lifting dryer:

-

Double

-

Machine test support:

-

Yes, with clients' materials

-

Screw:

-

Double-screw

Product Description

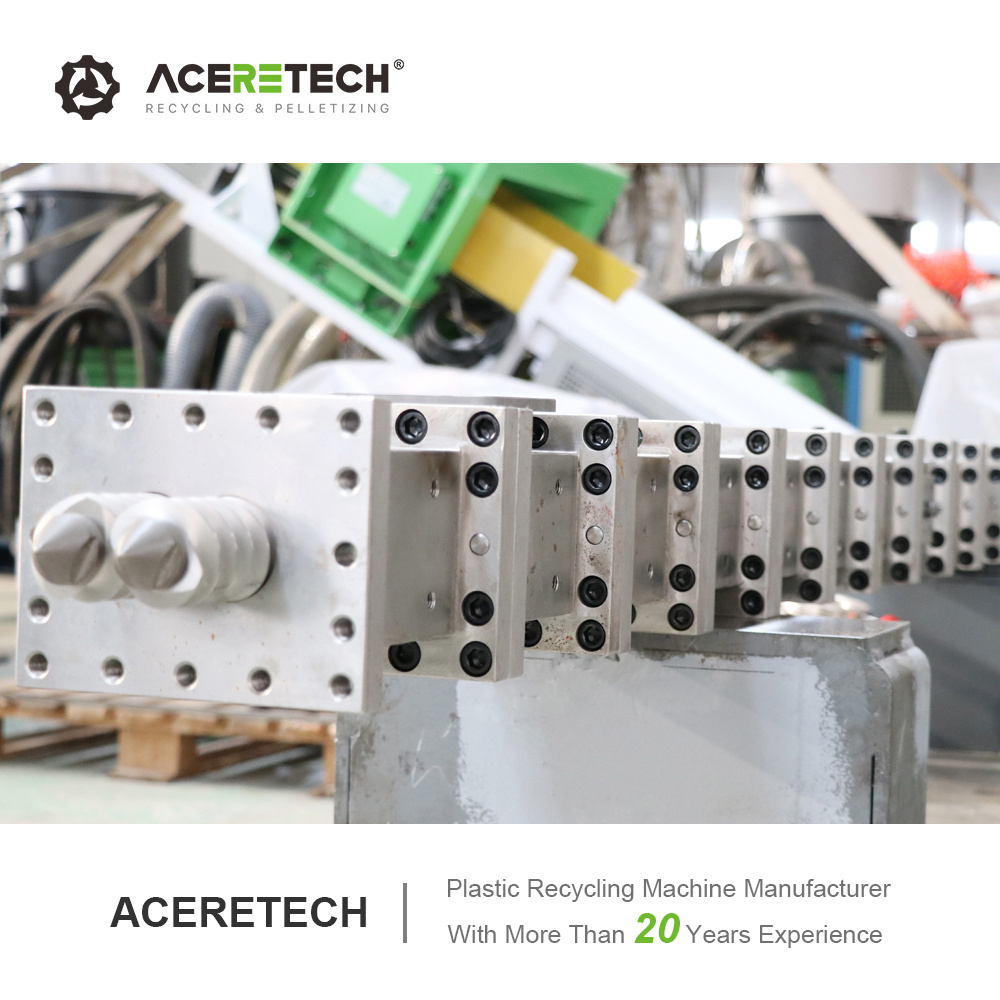

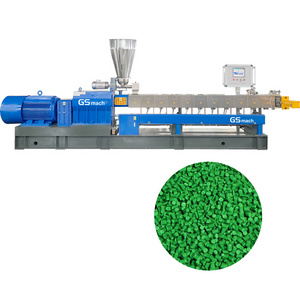

ACERETECH ATE Series Co-rotating Parallel Twin Screw Extruder pelletizing machine consists of motor drive, torque distribution gearbox, processing section, temperature controlling units, die section and down-stream pelletizing system, etc. Which is a specialized and reliable system.

ATE Twin Screw Extruder adopts modular design principle, component standardization manufacturing, which can present stable and reliable performance.

Aceretech Recyclable Plastics Include

●PP/PE/PET/ABS/PC flakes recycling

●PP/PE color masterbatch

●PC+ABS, PA+ABS, CPE+ABS, PP+EPDM, PP+SBS, PE, EVA filled with CaCO3

●PP, PA, PBT, ABS, AS, PC, POM, PPS, PET with glass fiber compounding

Suitable Products

Product Paramenters

|

SPECIFICATIONS

|

|

|

|

|

||||

|

Machine Model

|

ATE

|

|

|

|

||||

|

Target Recycled Material

|

PP,PE,PET,ABS,PC,PA,PBT,AS,OM,PPS,PET

|

|

|

|

||||

|

Final Product Shape

|

Particles

|

|

|

|

||||

|

System composition

|

Motor drive, torque distribution gearbox, processing section, temperature controlling units, die section and down-stream pelletizing system.

|

|

|

|

||||

|

Output Range

|

300kg/h-1500kg/h

|

|

|

|

||||

|

Diameter of screw

|

35.6-93mm

|

|

|

|

||||

|

L/D of screw

|

32-64

|

|

|

|

||||

|

Voltage Standard

|

According to the Voltage of the Customer's Location

|

|

|

|

||||

|

Optioanl device

|

Metal detector, Roll hualing off device, Masterbatch and additives feeder

|

|

|

|

||||

|

Technical services

|

Project design, factory construction, installation and recommendations, commissioning

|

|

|

|

||||

|

Machine

Size

|

ATE35

|

ATE52

|

ATE65

|

ATE75

|

ATE95

|

|

Dia. of screw(mm)

|

35.6

|

51.4

|

62.4

|

71

|

93

|

|

L/D

|

32-64

|

32-64

|

32-64

|

32-64

|

32-64

|

|

Screw speed Max(rpm)

|

600

|

600

|

600

|

600

|

600

|

|

Torque per shaft(Nm)

|

115

|

415

|

675

|

990

|

2365

|

|

Specific torqueT/A3

|

4.2

|

5.2

|

4.8

|

4.6

|

5

|

|

Output(kg/h)

|

40-80

|

150-250

|

200-400

|

300-700

|

550-1500

|

Product Detail

FEEDING

>>> As standard design, plastic flakes conveyed into the screw feeder by the screw loader, we can also install magnetic frame as optional in screw loader storage silo in case material with metal inside;

>>> Feeder motor is controlled by ABB/Schneider inverter; level sensor which installed in the hopper of screw feeder help realize automatic feeding.

MELT FILTRATION

>>> A regular single plate/piston double station screen changer or non-stop double plate/piston four-station screen changer can be installed on head of extruder to present significant filtration performance.

>>>

The requirements on the filter technology depend heavily on the quality of input material as well as the planned use of granules. high efficiency

PELLETIZING SYSTEM

>>> Die-face water ring pelletizing system set as the standard granulating method in ACSS-HTM system.

>>> Self-adjusting pelletiziin head for the best granulate quolity and long uptime thanks to consistently correct blades oressure. RPM of rotatory blades is automatic based on melt extruding pressure.

TWIN-SCREW EXTRUDER

>>> Screw diameter:

71 mm. L/D = 40

Main drive motor: AC 132 Kw.

Speed controlled by ABB/Schneider inverter. Rotary speed of extruder:

60~600rpm Processing section (barrels and screw elements).

SOFT WATER COOLING SYSTEM

>>> Material of input and output pipes is stainless steel. Manual valves to adjust flowing rate of cooling water; solenoid valves are to control opening and closing of cooling water flowing in.

VIBRATION DRY AND PACKING SYSTEM

>>> Advanced dewatering vibration sieve combing with horizontal-type centrifugal dewatering present high performance dried pellets and lower energy consumption..

INTELLIGENCE OPERATING

>>> Intelligence Start: One button only Following set logistical sequence and materials processing requirement, interlocked system modules can start by "one button only”

>>> Intelligence Stop: One button only Each related modular part in ACS system available to shut down by only one button.

>>> Emergency Stop: In case that uncertain risk occurred during machine running.

Company Video

FAQ

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME

● ACERETECH is original manufacturer.

● If you interested in our products and we can fulfill your request , you may pay a visit to ACERETECH Factory.

● The meaning of visiting supplier, since seeing is believing, ACERETECH Machinery with own manufacture and developed& research team, we can send you engineers and make sure the high efficiency after-sales service.

SEE ACERETECH MACHINE HOW TO ENSURE THE QUALITY

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strict control by inspecting personnel.

● Each assembly is in charge by a master who has working experience for more than 15 years

● After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory.

THE AFTER-SALE SERVICE OF ACERETECH MACHINERY

● After finishing the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.

● After the commissioning, we will package the equipment by the standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factories to do the installation and training.

● Engineers, sales managers, and after-sales service managers will form an after-sales team, online and offline, to follow the customers' project.

Hot Searches