It can refine different grades of oils and fats. Including all kinds of vegetable oils: soybean, peanut, cottonseed, rapeseed, jade, etc. are suitable for all oil-containing plants.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

11.2kw/380v

-

Dimension(L*W*H):

-

12.3x11.5x4.5mm

-

Weight:

-

3000 KG

-

Raw material:

-

Soybean

-

Function:

-

Making Edible Oil

-

Application:

-

Oil Production Line

-

Advantage:

-

Energy Saving Low Residual

-

Keyword:

-

Mini Oil Expeller

-

Feature:

-

High Oil Yield Efficiency

-

Material:

-

Stainess Steel

-

Character:

-

Professional Manufactuer

-

Press type:

-

Screw Cold Hot Oil Press

-

Product name:

-

Oil Refining Machine

Quick Details

-

Production Capacity:

-

3-4t/d

-

Place of Origin:

-

Henan

-

Brand Name:

-

BATM

-

Voltage:

-

11.2kw/380v

-

Dimension(L*W*H):

-

12.3x11.5x4.5mm

-

Weight:

-

3000 KG

-

Raw material:

-

Soybean

-

Function:

-

Making Edible Oil

-

Application:

-

Oil Production Line

-

Advantage:

-

Energy Saving Low Residual

-

Keyword:

-

Mini Oil Expeller

-

Feature:

-

High Oil Yield Efficiency

-

Material:

-

Stainess Steel

-

Character:

-

Professional Manufactuer

-

Press type:

-

Screw Cold Hot Oil Press

-

Product name:

-

Oil Refining Machine

BTMA SH-3 Cold hot Screw groundnut peanut oil processing btma refinery machine for sale palm oil refined

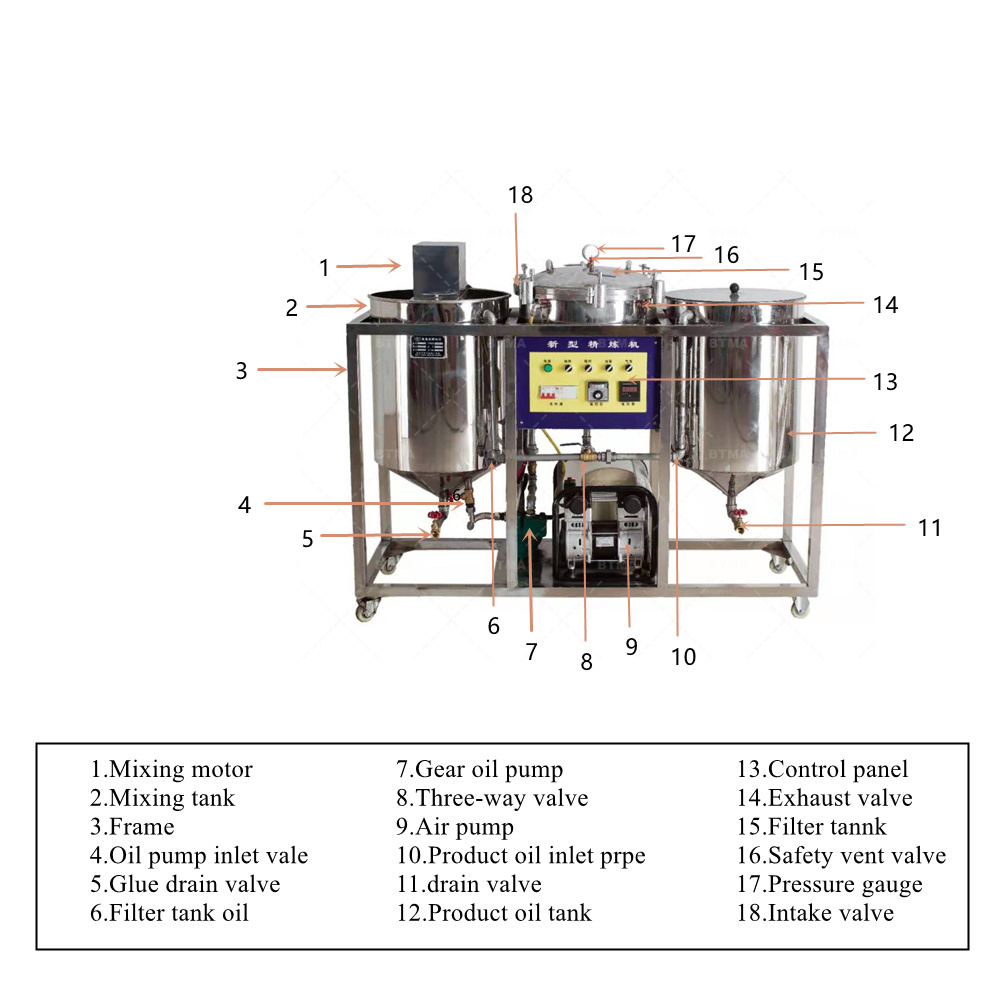

Products Introduction

The

small oil refiner

produced by our company is a high-tech product. The following are the products of our two barrels of

refining tank. It has the functions of

dephosphorization

,

deacidification

,

decolorization

and

degumming

. The refined oil can be directly sold to the local supermarket. It will bring you a

high profit return

.

Structure And Working Principle

Our Advantages

Edible oil refining machine features small scale edible oil refining machine coconut crude oil refinery machine features :

1) Simple structure in linear type, and easy in installation and maintenance.

2) Adopting advanced China famous brand components in electric parts and operation parts.

3) Full automatic and continuous working

4) Running in a high automation and intelligentization with no pollution.

5) Environmental friendly, low noise and power consumption

1) Simple structure in linear type, and easy in installation and maintenance.

2) Adopting advanced China famous brand components in electric parts and operation parts.

3) Full automatic and continuous working

4) Running in a high automation and intelligentization with no pollution.

5) Environmental friendly, low noise and power consumption

Product Paramenters

|

Model

|

6LK-50

|

|

Capacity

|

800-1000kg/d

|

|

Heating Power

|

6kw

|

|

Size

|

1.6x0.8x1.5m

|

|

Weight

|

160kg

|

|

Air Pump Power

|

1.1kw

|

|

Mixer Power

|

0.25kw

|

|

Oil Pump Power

|

0.37kw

|

Working Procedure

working process:

Crude oil - degumming (washing) - deacidification (alkali refining) - decolorization (white clay adsorption) - dehydration (heatdrying) - refined oil .

Crude oil - degumming (washing) - deacidification (alkali refining) - decolorization (white clay adsorption) - dehydration (heatdrying) - refined oil .

Degumming :

The purpose of Degumming Vegetable Oils is to remove Gums. All oils have hydratable and non-hydratable gums.

a.

Water Degumming: Hydratable gums are removed by treating oils with water and separating the gums. The gums can be dried to produce lecithin.

b.

Acid Degumming: Non-Hydratable gums are removed by treating oils with acids and separating the gums.

Neutralizing:

The purpose of Neutralizing Vegetable Oils is to remove Free-Fatty Acids (FFAs). Traditionally, FFAs are treated with caustic soda (NaOH). The reaction produces Soaps which are separated from the oil. Because trace amounts of soaps remain in the oil, the oil is either washed with water or treated with Silica.

Some processors prefer not to perform caustic neutralizing. Instead, they prefer Physical Refining in which the FFAs are evaporated from the oil under high temperature and vacuum. This process can be combined with deodorization step described under FFA stripping.

Physical Refining process is preferred because (a) it does not produce soaps; (b) it recovers fatty acids that provide better cost recovery; (c) there is smaller yield loss compared to caustic refining-especially for oils with higher FFAs; and (d) it is a chemical-free process.

Bleaching :

The purpose of Bleaching is to remove color pigments contained in Vegetable Oils. The oil is treated with Bleaching Clays that adsorb the color pigments. The clay is filtered and the clean bleached oil is stored for further processing. Process flow diagram is attached.

Deodorizing :

The purpose of Deodorizing Vegetable Oils is to remove odor substances. The oil is subjected to steam distillation under high temperature and vacuum to evaporate all odor substances. The resulting deodorized oil is almost bland and tasteless.

Application

The filtered oil is purer and brighter in color.

It can be widely used in refining a variety of oils.This is mini oil refinery have the decolorizing port,refinery port,refined oil pot,with the auto temperature equipment,can achieve crude oil degumming, deacidification, drying and decolorization function.The final oil reach national edible oil standard, directly filling to sale for small-scale processing and oil processing plant.

Details Images

Decolorization of oil can be achieved by adding active white clay to the tank shown on the right.

Our refining machines are equipped with corresponding motors.

It is generally installed at the bottom of the machine.

Drain valve, oil outlet switch, It can control this flow rate.

Simple and convenient operation, button operation after boot, no tedious manual operation

Features about our products

In addition, this is our three barrel refining machine, which has more capacity and more functions.

This is our four-barrel refining machine, it has all the refining functions, and the output is also large.

Paking & Delivery

Packing

We will load different sizes of packing according to different machine sizes, and small model is usually used by wooden box, bigmodel is used by 20ft and 40ft container. All oil press machines are packed by Standard export carton to guarantee our products well preserved during the transportation. Small spare parts are packed by wooden case or according to your requirements. If exported to European countries, wood frame will be fumigation. If the container is too tight, we will use the PE film according to the customer's special requirements.

Delivery

We are based on the actual needs of customers, to carry out tailor-made sales. By senior engineer to design scheme, after receipt of customer deposits we will manage production, regardless of the size of the equipment, we can deliver the goods in two weeks,when the machines are finished, we will send machines after customers transfer the balanced payment.

Shipping

The machines are shipped from our factory to nearest port by truck , And when the machines are shipped from our port to clients destination port by sea.

Certifications

Hot Searches