ustomize the packaging according to your requirements

- Product Details

- {{item.text}}

Quick Details

-

Name:

-

induction heating equipment manufacturers

-

Application:

-

induction metal heater hardening and quenching

-

Type:

-

Semi Automatic

-

Usage:

-

Automatic Control Operation

-

Color:

-

White

-

Certification:

-

CE ISO

-

Function:

-

Stable

-

Power:

-

300kw

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Uzbekistan, Brazil, Indonesia, Pakistan, India, Russia, Spain, Thailand

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

kechuang

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Free spare parts, Online support, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Name:

-

induction heating equipment manufacturers

-

Application:

-

induction metal heater hardening and quenching

-

Type:

-

Semi Automatic

-

Usage:

-

Automatic Control Operation

-

Color:

-

White

-

Certification:

-

CE ISO

-

Function:

-

Stable

-

Power:

-

300kw

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Uzbekistan, Brazil, Indonesia, Pakistan, India, Russia, Spain, Thailand

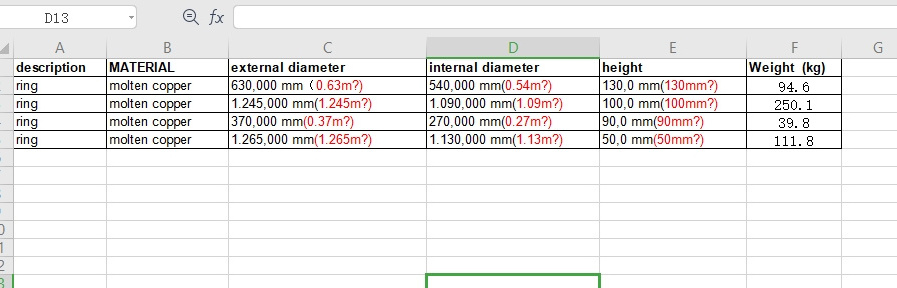

Products Description

|

Type

|

XZZ-300

|

|

Rated power (standard configuration)

|

300KW

|

|

Input voltage

|

380V/3 phase/50 hz

|

|

Power regulation range

|

5%-100%(Digital regulation)

|

|

Oscillating frequency

|

8-15KHZ

|

|

work pattern

|

Constant current, constant power arbitrary choice

|

|

Control core

|

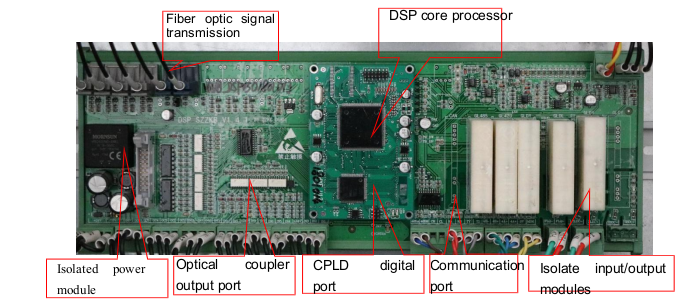

High performance dsp processor

|

Main characteristic

1.

Leading technology

The full digital intelligent power supply is controlled by DSP processor, and the control process, data operation, parameter storage and other aspects of the system are all processed in digital form by using digital control technology. Environmental changes such as temperature changes will not affect the internal processing process and results of the system.

2.

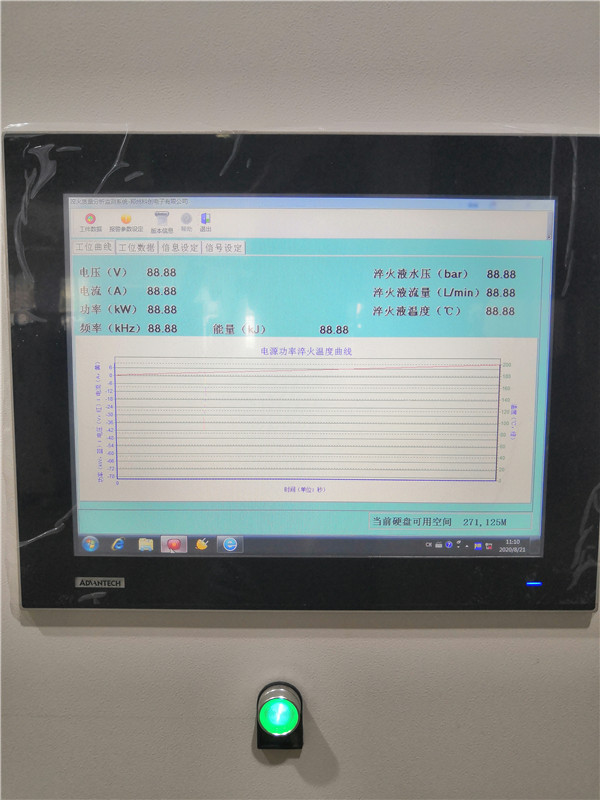

Touch screen display

The working state and working parameters of the equipment can be visually displayed on the touch screen. The display parameters include: working frequency, oscillation current, dc voltage, dc current, output power and other parameters.Working state includes load matching indication and other functions。

3.

Intelligent protection system

Condition of power supply in normal work, if suddenly will automatically latch fault alarm, at this time, all kinds of protection and fault alarm signal, such as: light capacitor, power cabinet to open the door, IGBT power speed protection, diode special protection, over voltage, over current, lack of phase, water flow, water temperature and other protection, to ensure that the equipment is reliable and durable.

4.

Powerful communication function

Rs485/232 interface is reserved to exchange data with external controller (industrial computer, industrial touch screen, laptop, etc.) or central control room.

5.

Fault self-diagnosis and online processing

When there is an alarm due to wrong operation or special working condition, the touch screen will display the fault content, and click the corresponding fault help to query the corresponding fault solution.

6.

Signal transmission USES fiber transmission

The electromagnetic environment inside the power supply cabinet is complex, and the transmission of weak electric signals (such as drive signals, protection signals, feedback signals, etc.) is prone to electromagnetic interference, while light is not affected by the electromagnetic environment. Therefore, these important signals are transmitted by optical fiber, which improves the overall stability and reliability of the equipment.

Product Application

1.

Heat treatment for various hardware and tools, such as plier, wrench, hammer, ax,screwing tools.

2.·Heat treatment for various automobile and motorcycle fittings, such as crankshaft,connecting rod, piston pin, chain wheel, aluminum wheel, valve,rock arm shaft,semi drive shaft, small shaft and fork.

3.Heat treatment for various electric tools, such as gear and axes.

4.Heat treatment for machine tools,such as lathe deck and guide rail. 5. Hardening for various hardware metal parts and machined parts, such as shaft,gear chain wheel, cam,chuck and clamp.

6. Heating for hardware molds, such as small-size mold, mold accessory and inner hole of mold.

7. Annealing of various stainless steel products, such as stainless steel basin,annealed and extruded can, annealed folded edge, annealed sink, stainless steel tube, tableware and cup.

·8. Forging of various other metal work pieces, such as round steel, sheet/plate, pipe and others.

Why choose us

Our company

Company profile

Zhengzhou kechuang Electronics Co.,Ltd was established in 31th,August 2001.Kechuang has been developed hundreds of products which has been widely spread and enjoyed by both national and international market since 2001. In 2016,in order to meet the high-end users' demand both in domestic and overseas.We produced much higher performance,higher percision and higher cost-effective intelligent IGBT power supply. Kechuang always has always regard "more energy-saving","more reliable" as the product development direction.Completing the products automatic,intelligent and robotic functions , which leads in the first of national induction heating technology.All of our products and technologies can provide

.

Exhibition

Certifications

Packing & Delivery

delicately packed

Hot forging machine welding equipment annealing furnace induction heater packed in wooden.

We can also

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

* Engineers available to service machinery overseas.

Hot Searches