- Product Details

- {{item.text}}

Quick Details

-

Commodity name:

-

Cutters Concrete Scarifier,tungsten carbide scarifier cutters

-

Content:

-

WC + Co

-

O.D.:

-

40~82mm

-

I.D.:

-

15~30mm

-

Thickness:

-

6.0~8.0mm

-

Tip:

-

5, 6, 8 or 10 points

-

Surface:

-

galvanize

-

Certification:

-

ISO9001:2000 Certificate

-

Material:

-

100% virgin material tungsten carbide

-

Application:

-

used for line removal on road ways on Asphalt and Concrete

Quick Details

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

tungsten carbide scarifier cutters

-

Model Number:

-

tungsten carbide scarifier cutters

-

Commodity name:

-

Cutters Concrete Scarifier,tungsten carbide scarifier cutters

-

Content:

-

WC + Co

-

O.D.:

-

40~82mm

-

I.D.:

-

15~30mm

-

Thickness:

-

6.0~8.0mm

-

Tip:

-

5, 6, 8 or 10 points

-

Surface:

-

galvanize

-

Certification:

-

ISO9001:2000 Certificate

-

Material:

-

100% virgin material tungsten carbide

-

Application:

-

used for line removal on road ways on Asphalt and Concrete

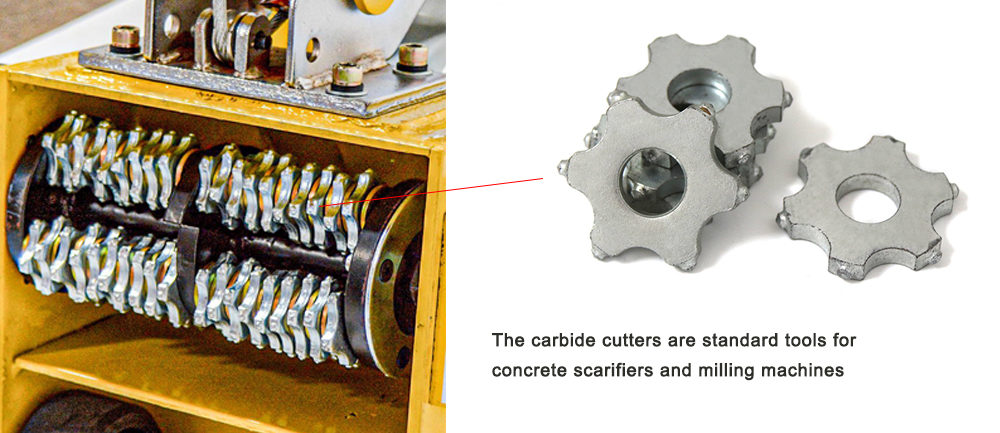

Tungsten carbide scarifier cutters

Tungsten carbide scarifier cutters are tools used for surface preparation and removal of coatings, adhesives, and other materials from concrete, asphalt, and other surfaces. They are made of tungsten carbide, which is a hard and durable material that can withstand high temperatures and abrasion.

The scarifier cutters have a variety of shapes and sizes, including flails, stars, and blocks, which are attached to a drum or shaft and rotate at high speed to cut and remove the surface material. They are commonly used in construction, renovation, and maintenance projects to prepare surfaces for repair or resurfacing.

Tungsten carbide scarifier cutters are preferred over traditional steel cutters because of their longer lifespan, higher efficiency, and lower maintenance costs. They are also environmentally friendly and can be recycled.

|

Product name

|

Number of teeth

|

Outer diameter (mm)

|

Inner hole (mm)

|

Thickness (mm)

|

|

Milling machine blade

|

Five stars

|

43

|

15.5

|

6

|

|

Milling machine blade

|

Six stars

|

46

|

15.5

|

6

|

|

Milling machine blade

|

Small eight Stars

|

60

|

18/20

|

6

|

|

Milling machine blade

|

mid-eight

|

68

|

26

|

6

|

|

Milling machine blade

|

Big Eight stars (US standard)

|

83

|

30

|

8

|

|

Milling machine blade

|

Big Eight stars (European standard)

|

83

|

30

|

8

|

|

Milling machine blade

|

Twelve stars (old model)

|

80

|

26/30

|

8

|

|

Milling machine blade

|

Twelve stars (Pattern)

|

83

|

35

|

10.9

|

|

Asphalt blade

|

pentadentate

|

40

|

15

|

22

|

|

Asphalt blade

|

Minor sextant

|

55

|

18

|

19

|

|

Asphalt blade

|

Major sextant

|

80

|

30

|

19

|

Features

1. Hardened steel body with raw material tungsten carbide tips.

2. heat treatment, high hardness and wear risistance

3. Various size for your selection

4. Reasonable price.

1. Hardened steel body with raw material tungsten carbide tips.

2. heat treatment, high hardness and wear risistance

3. Various size for your selection

4. Reasonable price.

We are providing superior crude carbide material with higher wearing resistance and great consumption obstruction.

We are providing the exact quality items with exacting quality control after complete reviewing and testing hardware.

Precision resilience to the predetermined shape and size. Large load of standard measurement for quick conveyance.

FAQ

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment

3. How long is your delivery time?

Generally it is 3~5 days if the goods are in stock; or it is 15-25 days if the goods are not in stock, depending on order quantity.

4. Do you provide samples? Is it free or extra?

Generally we don't provide free samples. But we can deduct sample cost from your bulk orders.

5. What is your payment terms and method?

Payment<=1000USD, 100% in advance.

Payment>=1000USD, 30% T/T in advance, balance before shippment.

We accept T/T, L/C, Alipay, PayPal, Western Union Wechat and so on.

Hot Searches