- Product Details

- {{item.text}}

Quick Details

-

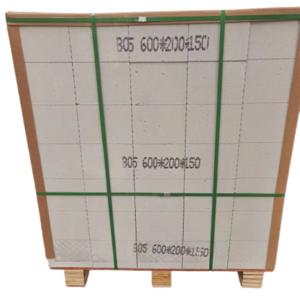

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

BAILUN

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1550*650*1300mm

-

Marketing Type:

-

Hot Product

-

Weight (KG):

-

800 kg

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, Autoclaved aerated concrete block (AAC)

-

Brick Raw Material:

-

Cement

-

Production Capacity (Pieces/8 hours):

-

10-60 m3/h

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

BAILUN

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1550*650*1300mm

-

Marketing Type:

-

Hot Product

-

Weight (KG):

-

800 kg

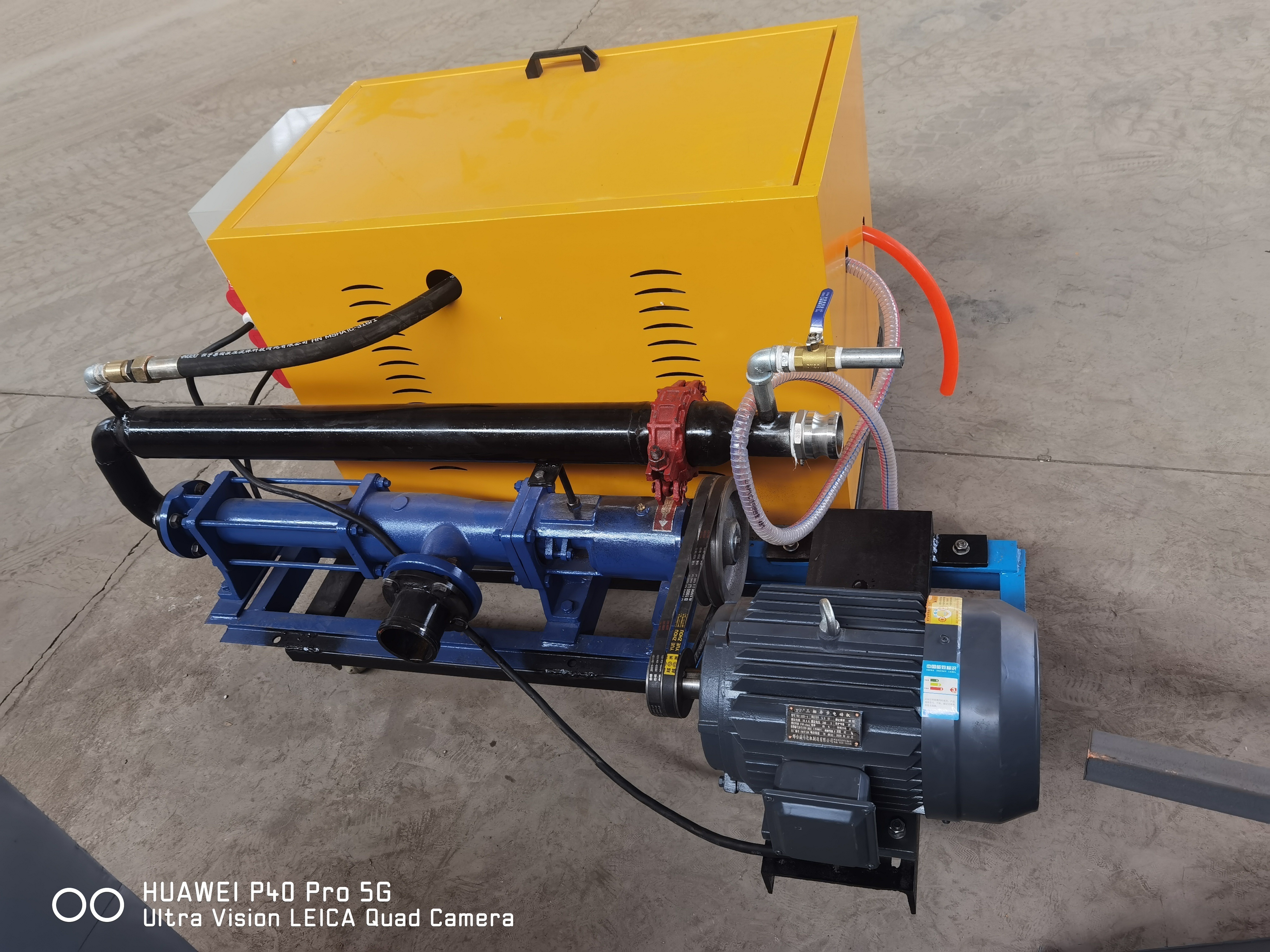

Concrete Cement foaming machine for ground and roofing insulation

1.Machine introduction of Concrete Foam Machine

This line use the technology of pump transportation.The whole process line include four parts: feeding conveyor, concrete mixing

machine, foam machine used in block , foam agent and pump, the transportation capacity is 10~15m³/h, the max level transportation

distance is 50m, the max horizon distance is 400m.

Applications:

Floor/roof casting

Block

Wall panel

Framed wall and house structure casting

Subway and coal mining backfill

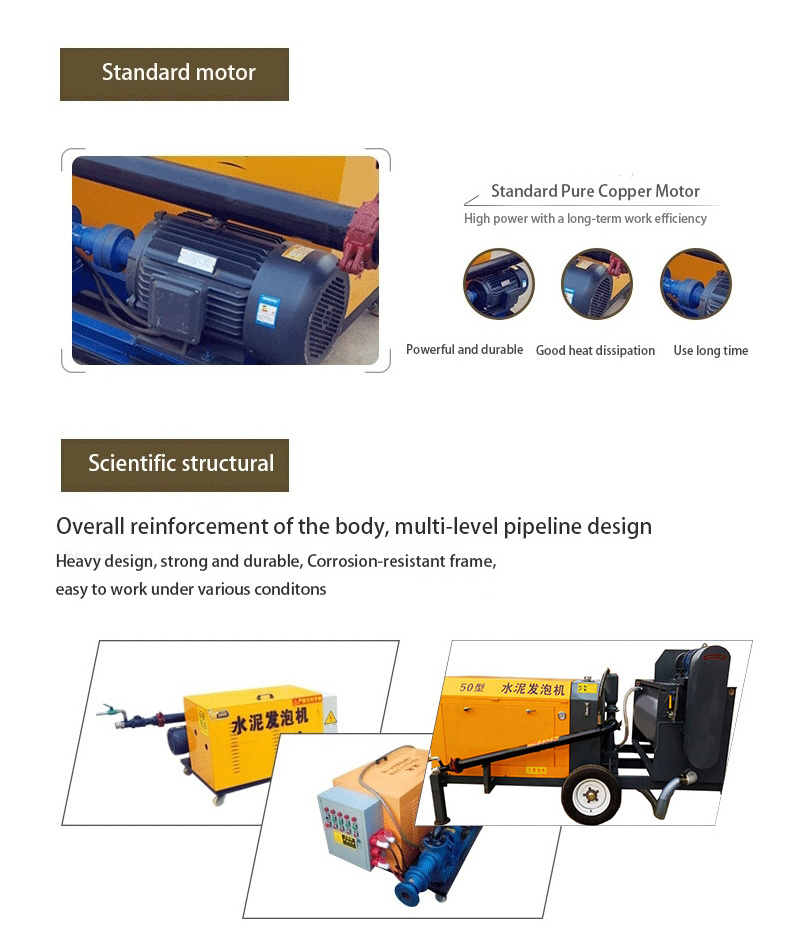

Machine features:

1).the machines is with wheels, then the process line is easy to move, so it can be used for many places, such as construction

plant, block plant, and so on.

2).Light weight, the main machine is only 600kg, you also can equip with the forklift, it will save more time, labour and costLow

consumption, the whole line is about 15kw.

3).Use the pump to transport the cement foam

It can use plant type foam agent, animal type foam agent and synthetic foam agent.

You can adjust the volume of the raw material.

2.Technical Parameter

Various Models Contact Us

|

Model

|

BLM-FP10

|

BLM-FP20

|

|

Capacity

|

10m³/h

|

20m³/h

|

|

Conveying method

|

screw pump

|

Double hydraulic pump

|

|

power

|

7.5kw

|

15kw

|

|

Vertical distance

|

40M

|

100M

|

|

horizontal distance

|

200M

|

500M

|

|

outlet pressure

|

8Mpa

|

12Mpa

|

|

Dimension

|

1400*1000*840mm

|

2300*1000*1600mm

|

|

Weight

|

800kg

|

1100kg

|

3.Product Advantages

4.Our services:

Before sales services:

1. Answer consultation from users according to users' demands, help user chose suitable type.

2. Offer design drawing and solution accroding to users' demands.

During sales services:

1. Produce and ship the goods for customer safe and timely;

2. If need, arrange engineer to train works how to operate the machine rightly.

3. Highly inspecting equipments in every working procedure, quality comes first;

After sales services:

1. Give a clear reply upon customers questions within 24 hours;

2. If necessary, we send engineer to user's site to solve the problem timely;

3. Reture visti at regular intervals;

4. Establishing user's record;

5. One year guarantee and whole life services and techinal support;

6. Supply latest industrial informaion.

1. Give a clear reply upon customers questions within 24 hours;

2. If necessary, we send engineer to user's site to solve the problem timely;

3. Reture visti at regular intervals;

4. Establishing user's record;

5. One year guarantee and whole life services and techinal support;

6. Supply latest industrial informaion.

5.FAQ:

1.You are the trading company or manufacture company ?

we are the 10 years' manufacture experiences manufacture company in China.

2.what is your machine advantage than other foam concrete machines?

A.Our machine can make the foaming , mix , pump together.

B. Our machine can automatically adjust the density.

C. Our foam concrete machine can easy to control and operate .

3.what is the density your machine can arrive ?

From 300-800kg/m³ , if your have any other requirements , we can try to satisfy you .

4. how to guarantee the machine work well before shipping ?

We have our professional testing department ,we will have twice testing when we finish our machine and before shipping.

5. Warranty period ?

The warranty will be one year from the date of shipment. Any detected parts during this period caused by the quality of products

will be replaced by seller free of cost (exclude wear and tie parts), improper operation and other manmade reasons are excluded.

Hot Searches