- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.2-1.0mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HX

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

5400X1000X1500MM

-

Weight:

-

2600 kg

-

Feeding width:

-

Other,Based on design drawing

-

Marketing Type:

-

New Product 2023

-

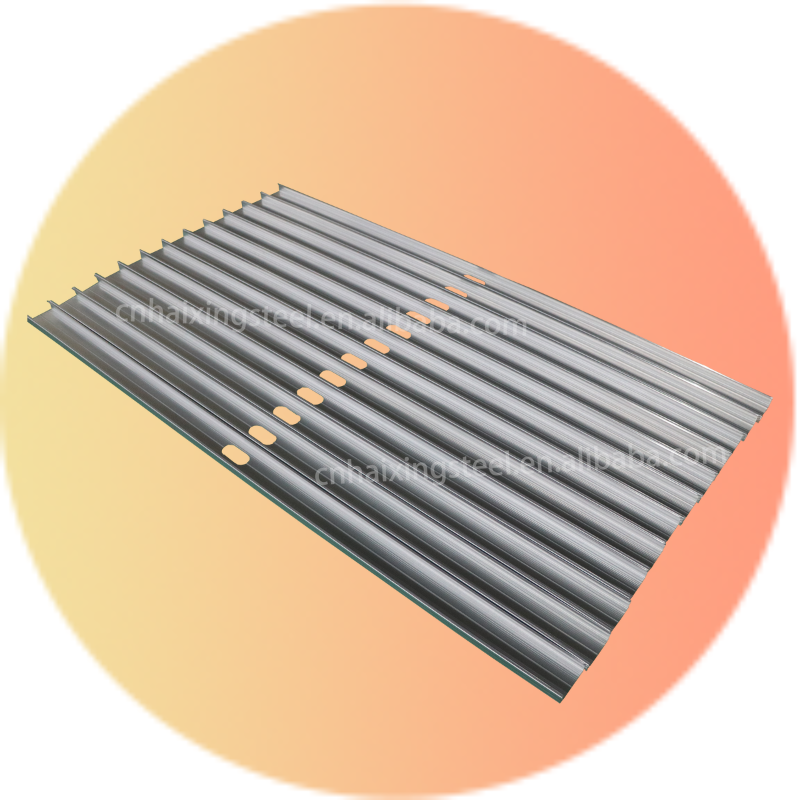

Product name:

-

drywall manufacturing machine

-

Usage:

-

Wall Panel

-

Raw material:

-

PPGI PPGL GI GL

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Main frame:

-

350H Steel

-

Control system:

-

PLC(imported Brand)

-

Shaft material:

-

High Grade No.45 Forged

-

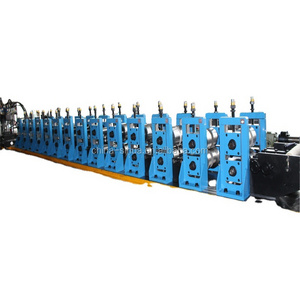

Machine type:

-

Roll Forming Mahcine

-

Plc:

-

DETLA

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

60 m/min

-

Rolling thinckness:

-

0.2-1.0mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HX

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

5400X1000X1500MM

-

Weight:

-

2600 kg

-

Feeding width:

-

Other,Based on design drawing

-

Marketing Type:

-

New Product 2023

-

Product name:

-

drywall manufacturing machine

-

Usage:

-

Wall Panel

-

Raw material:

-

PPGI PPGL GI GL

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Main frame:

-

350H Steel

-

Control system:

-

PLC(imported Brand)

-

Shaft material:

-

High Grade No.45 Forged

-

Machine type:

-

Roll Forming Mahcine

-

Plc:

-

DETLA

Product Description

|

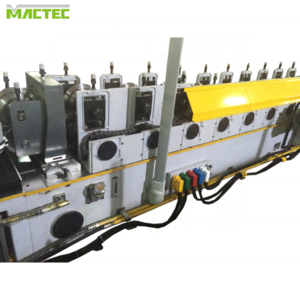

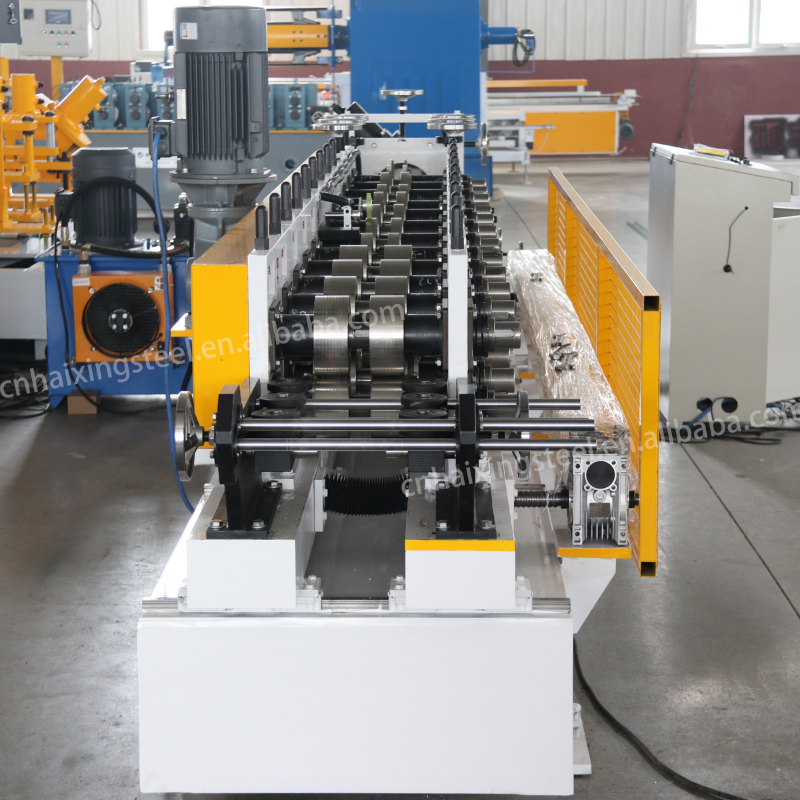

Metal stud and track roll forming machine parameters

|

Steel keel machine parameters

|

|

|

Suitable to process

|

Color alu-zinc steel strips

|

|

|

Roller

|

12Rows plus leveling device

|

|

|

Dimensions

|

5.4*1*1.5m

|

|

|

Motor Power

|

3Kw

|

|

|

Pump Station Motor

|

3Kw.Lichao Brand

|

|

|

Thickness of the plate

|

0.3-0.8mm

|

|

|

Productivity

|

10-15m/min

|

|

|

Material of the cutting blade

|

Cr12,Quenched treatment 58℃-60℃

|

|

|

Diameter of the roller

|

Φ50mm

|

|

|

Weight

|

About 2600kgs

|

|

|

Main structure of the machine

|

Square steel frame

|

|

|

Processing precision

|

Within 1.0mm

|

|

|

Side panel of machine

|

16mm

|

|

|

Chain Wheel and Cycle Chain

|

1 Inch

|

|

|

Voltage

|

380V 50Hz 3phases or as customer's need

|

|

|

Control system

|

PLC control (Delta)

|

|

|

Frequency system

|

Delta

|

|

|

Drive mode

|

Gear driver

|

|

|

Touch screen

|

Delta

|

|

|

Rolling materials

|

45# forging steel with chromium plate

|

|

|

Length Tolerance

|

±2mm

|

|

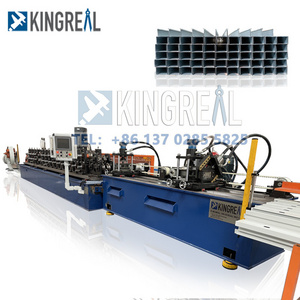

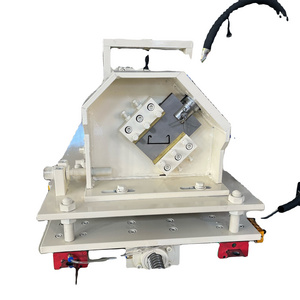

Metal stud and track roll forming machine

picture details

Spare parts of

Steel keel machine

|

Passive Decoiler

|

1Set

|

|

Feeding Platform with Pre-cutter

|

1Set

|

|

Roll Forming Machine

|

1Set

|

|

PLC Control System

|

1Set

|

|

Hydraulic Cutting System

|

1Set

|

|

Exit Rack for roofing production

|

2 Pieces of 3 Meters

|

|

Spare parts

|

One carton box

|

Machine production process

Drawing confirmation:

After confirming the final profile with the customer, the team of 12 engineers worked out detail workable parts CAD drawings; After 5 recheck, the production manager arrangement the material for all machine parts;

S

tart production:

Our company owns 12sets rough lathe machine, 20sets precise lathe machine, and 30 sets shearing machine, all machine parts start to manufacture.

P

roduct Inspection:

Our company Own 3sets hard test machine, and 4sets surface thickness Chromium test machine.

Roller and shaft: Our Inspect team test 90% wheels and shafts, confirm all parts size precise and performance after processing. Our Inspect team test all roller surface, confirm all part surface paint above 5um.

Mainframe and medium plate: Our Inspect team tests the mainframe and plate cutting precise.

A

ssembling machine:

5 workers assemble and welding one machine body frame by three days.

Machine painting:

Putty ensure weld parts surface smoothly, and environment-friendly paint ensures protect worker body and environment.

M

achine Manual use test:

Confirm the output sheet tolerance within 2mm.

C

utter production:

According to the finally manufacture sheet, confirm the blade precise profile, Cr12 MOV steel cutting knife finished by laser cutting.

S

torage:

To protect the machine surface clear and without damage, we paint again and package by the film.

Application of

Steel keel machine

Packing & Shipping

a.The main body of machine with water-proof plastic, then fixed to container by 8mm diameter steel wire and angle iron.

b.Rollers and shafts are covered with anti-rust oil.

c.PLC control system and motor pump are packed with waterproof paper and plastic film.

d.Spare parts in a carton box.

e.Manual decoiler was nude packing.

f.The output-table put into a carton box.

g.If the machine is too long, we will divide it into two parts and pack them in one package with steel wire.

h.Fit for ocean shipping.

Hot Searches