- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

standard or customized

-

Power (kW):

-

124 kW

-

Weight (KG):

-

35000 KG

-

Powder granule size:

-

6-30 Mesh

-

Tyre recycling Step 1:

-

Ring Cutter

-

Tyre recycling Step 2:

-

Loop Machine

-

Tyre recycling Feature 1:

-

One year's warranty time and life time maintain service

-

Tyre recycling Feature 2:

-

Final granule size 5-24 mesh, purity ≥ 99.7%

-

Tyre recycling Feature 3:

-

Capacity: 5-6 tons per day

-

Certification:

-

CE/SGS/CNAS/IAF

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Guangyue

-

Voltage:

-

220-440v, can be customized

-

Dimension(L*W*H):

-

standard or customized

-

Power (kW):

-

124 kW

-

Weight (KG):

-

35000 KG

-

Powder granule size:

-

6-30 Mesh

-

Tyre recycling Step 1:

-

Ring Cutter

-

Tyre recycling Step 2:

-

Loop Machine

-

Tyre recycling Feature 1:

-

One year's warranty time and life time maintain service

-

Tyre recycling Feature 2:

-

Final granule size 5-24 mesh, purity ≥ 99.7%

-

Tyre recycling Feature 3:

-

Capacity: 5-6 tons per day

-

Certification:

-

CE/SGS/CNAS/IAF

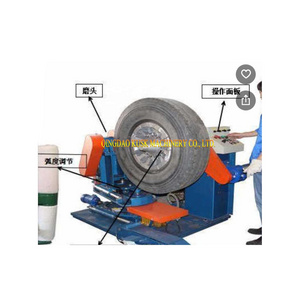

Used tyre pressure testing machine / used tyre retreading tire inspection machine

General:

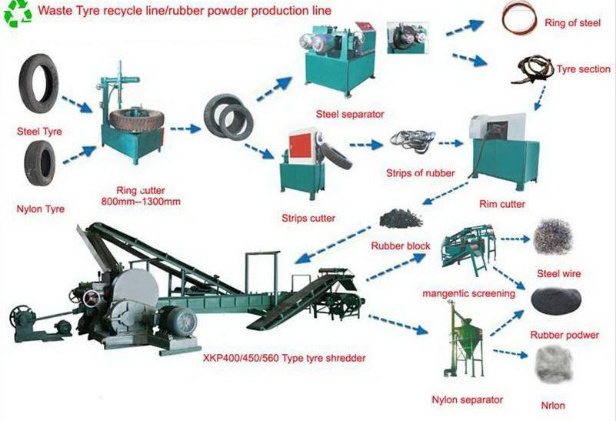

This production line including main machine and accessorial equipment, it is used for recycling scrap-tire (steel tyre and textile tyre), the final product is rubber powder or reclaimed rubber

Producing Flow:

Waste tire→cutting circle→cutting strip→cutting dice→crushing filtering→magnetic separating filtering→finished products→rubber powder/steel wire/nylon.

Features of Tyre Recycling Production Line:

Process tires size 600-1200 mm.

Final granule size 5-24 mesh, purity ≥ 99.7%.

Space for installation is about 300-400 m2

One year's warranty time and life time maintain service.

Capacity: 5-6 tons/day.

Please choose us,Because we are More Professional than other!

Provide USD1000 Spare parts for free!!!

Semi-aotomatic wast tire recycling line Description:

|

Size |

1-30mesh rubber powder (can adjust) |

|

Capacity |

About300-1500kg/h rubber powder |

|

Installed gross capacity |

About 103.45kw (electric power:380V,50HZ- if yours different with 380V,50HZ , just need add 800USD for change it) |

|

suitable max tire |

no more than 1200mm in diameter |

|

Equipment floor area |

300 SQM |

|

Man power |

5-6 workers to operation |

Main Equipment:

|

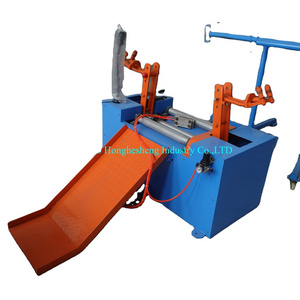

1. Ring cutter Purpose :To cut the steel ring from the tyre |

2. Bead wire separator Purpose: To Separate the steel ring from the rubber after 1 step. |

3. Strips cutter Purpose :To cut the steel ring from the tyre |

|

|

|

|

4. Block cutter Purpose: To Cut the strip into block |

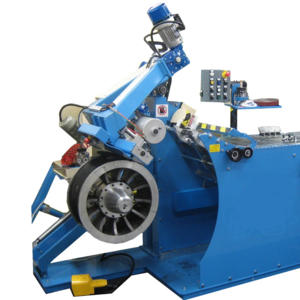

5.Double-roll rubber crusher Purpose:Used to break waste tire block into 0-30mesh rubber power and separate the steel wire from the rubber block at the same time. |

6. Auxiliary equipment Big vibrating sieve Small vibrating sieve Big belt conveyor Small belt conveyor Magnetic |

Used tyre pressure testing machine / used tyre retreading tire inspection machine

Used tyre pressure testing machine / used tyre retreading tire inspection machine

Packaging

Nude packing & Electricity box wooden splints packaging.

Shipping

Delivery Port:QingDao Port

Price Term

1. To be paid by T/T 30% of total amount in advance.

2. To be paid the balance by T/T 7 days before shipment.

Used tyre pressure testing machine / used tyre retreading tire inspection machine

Used tyre pressure testing machine / used tyre retreading tire inspection machine

1.pre-sale services

Act as a good adviser and assistant of client enable them to get rich and generous returns on their investments.

1)select equipment model

2)design and manufacture products according to clients' special request

3)train technical personnel for clents.

2.services during the sale

1)Recheck and accept products ahead of delivery

2)Help clients to draft solving plans

3.after-sale services

1)provide considerate services to minimize client's worries.

2)Help client to solve the assembly question

3)take responsibility if any technical problem