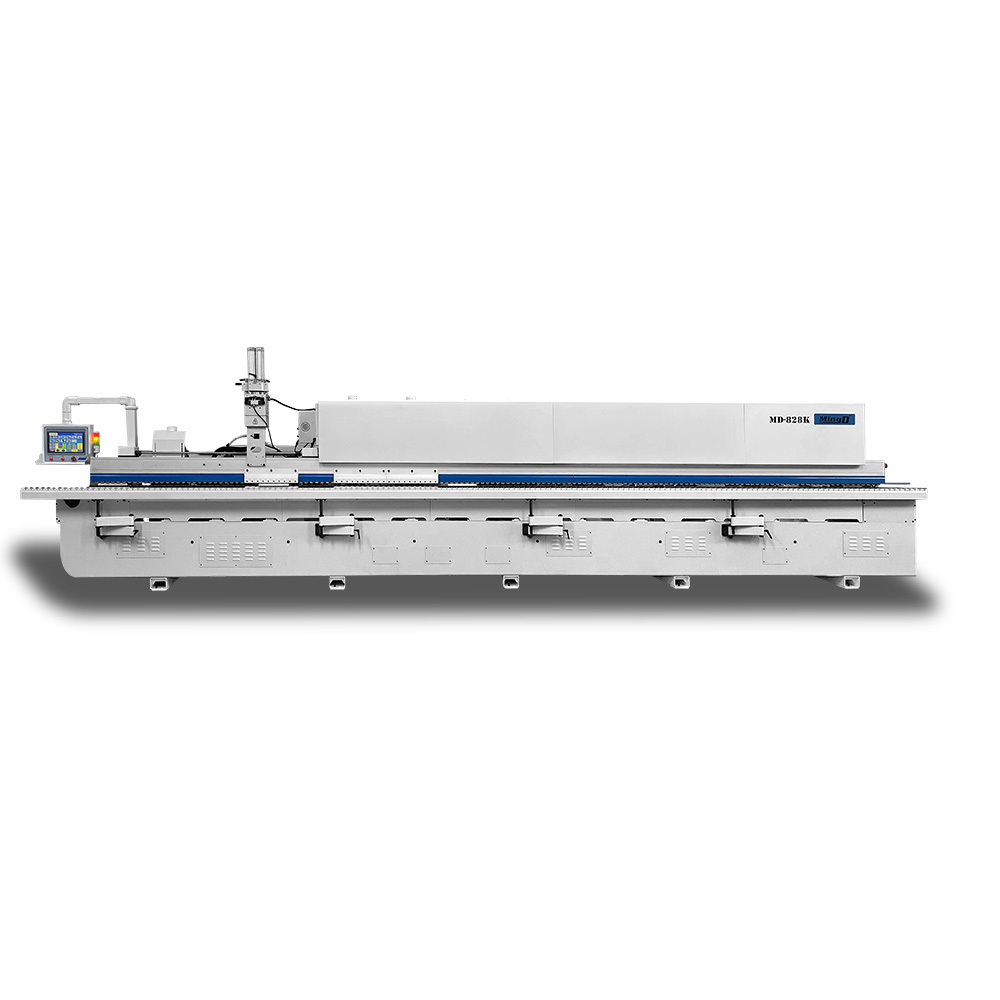

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

11200*1050*1900mm

-

Power (kW):

-

29.87KW

-

Weight (KG):

-

3000 kg

-

Panel Feed Speed(m/min):

-

26m/min

-

Model:

-

MD-828K

-

Vacuum port:

-

100*10

-

Working Pressure:

-

0.6Mpa

-

Total power:

-

29.87KW

-

Feed speed:

-

20-26m/min

-

Electric lifting:

-

0.37KW

-

Panel Thickness:

-

10-60mm

-

Sheet length:

-

120mm

-

Panel Width:

-

60mm

-

Edge thickness:

-

0.4-3mm

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

MINGD

-

Voltage:

-

220V/380V/440V/ customized

-

Dimension(L*W*H):

-

11200*1050*1900mm

-

Power (kW):

-

29.87KW

-

Weight (KG):

-

3000 kg

-

Panel Feed Speed(m/min):

-

26m/min

-

Model:

-

MD-828K

-

Vacuum port:

-

100*10

-

Working Pressure:

-

0.6Mpa

-

Total power:

-

29.87KW

-

Feed speed:

-

20-26m/min

-

Electric lifting:

-

0.37KW

-

Panel Thickness:

-

10-60mm

-

Sheet length:

-

120mm

-

Panel Width:

-

60mm

-

Edge thickness:

-

0.4-3mm

Product Paramenters

|

Model

|

MD-828K

|

Feed speed

|

20-26m/min

|

|

Overall Size(L x W x H)

|

11200*1050*1900mm

|

Electric lifting

|

0.37KW

|

|

Working Pressure

|

0.6Mpa

|

Panel Thickness

|

10-60mm

|

|

Total power

|

29.87KW

|

Sheet length

|

≧120mm

|

|

Vacuum port

|

φ100*10

|

Weight

|

3000kg

|

|

Panel Width

|

≧60mm

|

Edge thickness

|

0.4-3mm

|

Products Description

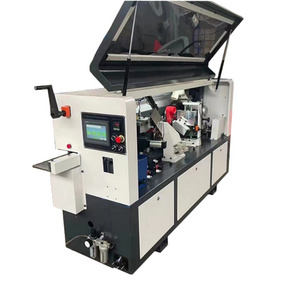

Touch screen

The woodworking industry's leading touch screen, fast response, do not miss touch

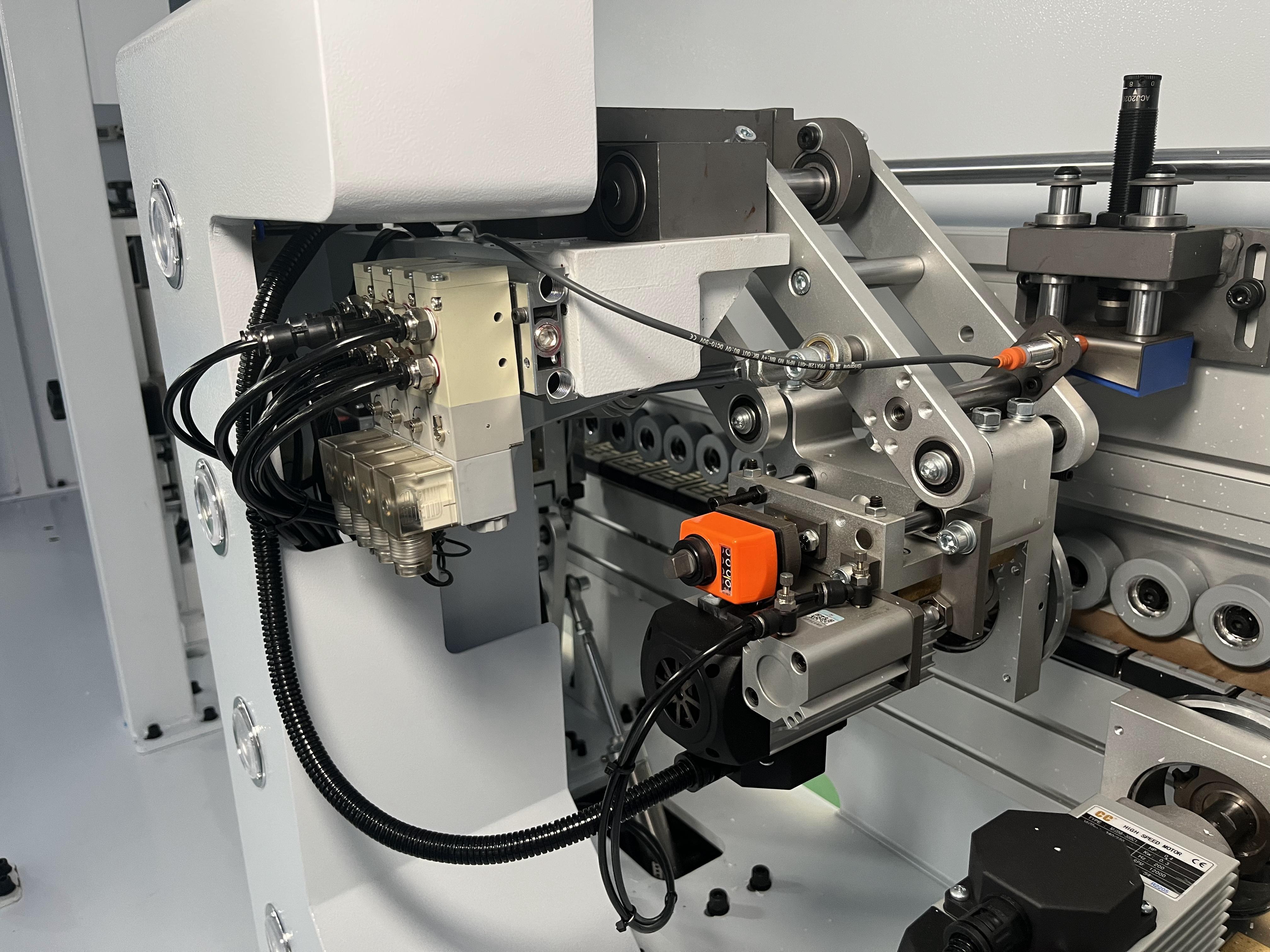

Pre-miling

The diamond pre-milling cutter milled the corrugated marks and excess burrs of the spiral trimming knife to make the edge of the board more fit to the edge sealing strip, and the bonding is more firm and more beautiful. Pneumatic control of the pre-milling seat, more accurate, more convenient control.

Gluing

The amount of glue on the fast sol is large, and the glue is fast for the edge sealing of the wooden door. The amount of glue can be adjusted to the thinnest, the edge sealing effect can hardly see the glue line, and the effect is better than the traditional glue pot. Automatic glue extraction, saving manpower, automatic constant temperature, automatic glue.

End cutting

Cut off the redundant edge banding at both ends of the plate (the cylinder has 2 pressure regulating valves and 1 pressure relief

valve). The air pressure is more stable, and the end is more stable.

valve). The air pressure is more stable, and the end is more stable.

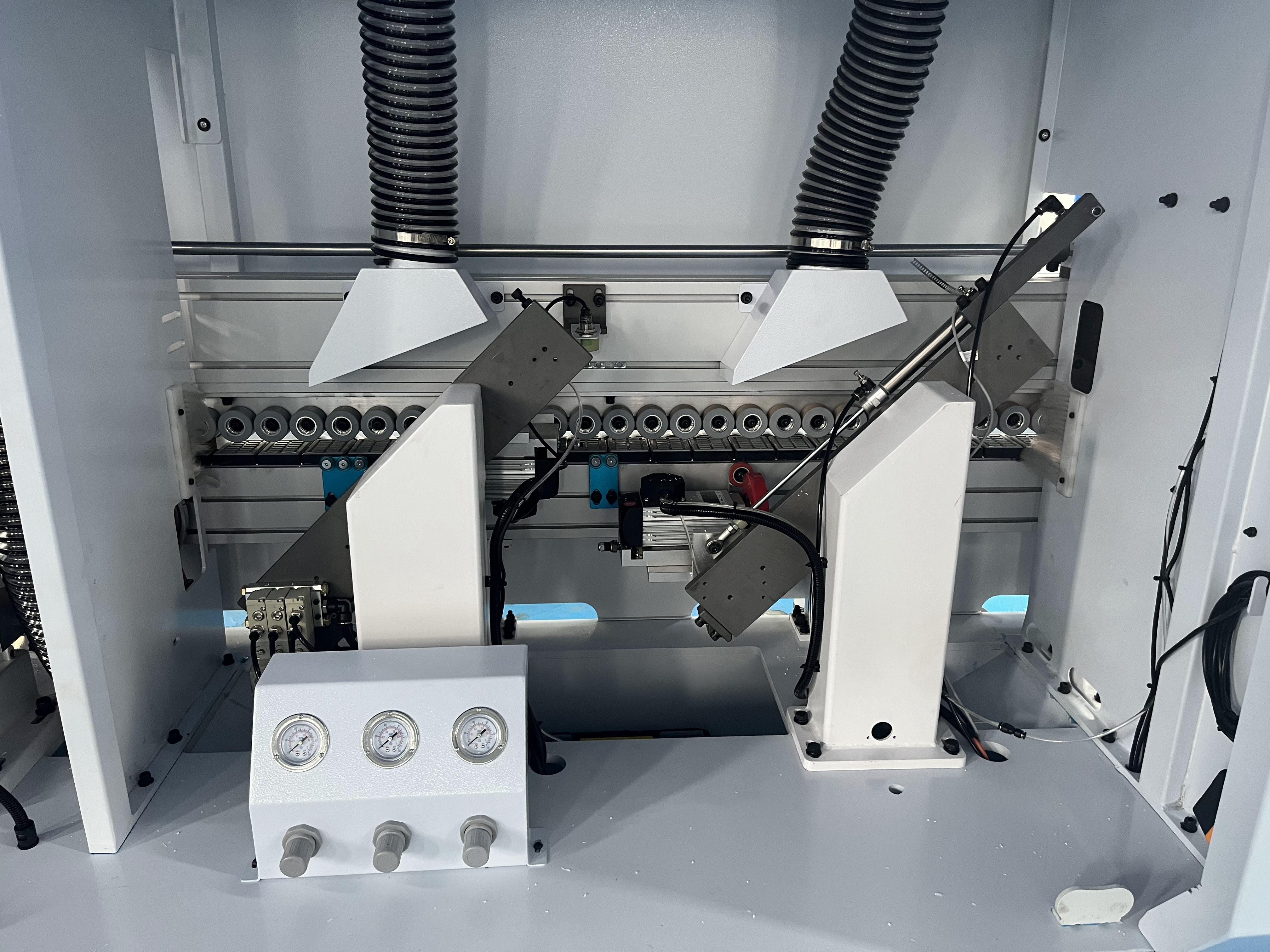

Rough trimming

The structure of automatic profiling and high-frequency high-speed motor is adopted to ensure the smoothness of the upper and

lower parts of the trimmed plate. It is used to repair and process the excess edge banding material above and below the edge band

of the plate

lower parts of the trimmed plate. It is used to repair and process the excess edge banding material above and below the edge band

of the plate

Fine trimming

The six-edged R knife trims off the excess edge banding and the trimming is more beautiful.

Corner Trimming

Corner rounding unit for soft and postforming workpieces for the processing of the ends of the panel with 0.4-3.0 mm edge material

and 10-40 mm workpiece height,

With 2pcs 0.37kw motors.

suitable for straight workpiece edges.

Minimum workpiece length 250mm (with a 18 mm height).

and 10-40 mm workpiece height,

With 2pcs 0.37kw motors.

suitable for straight workpiece edges.

Minimum workpiece length 250mm (with a 18 mm height).

Scraping

Designed for upper flat scraping and lower R scraping according to the characteristics of bevel; The super hard alloy R knife

scrapes the fine lines of the edge banding strip to make it smooth.

scrapes the fine lines of the edge banding strip to make it smooth.

Flat

Scraping

Use a small blade to perform the final flat edge scraping on the material

Buffing

Use a cotton polishing wheel to clean the processed plates, and polish the edge-sealing end surface smoother.

Hot Searches