- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Guangmao Machinery

-

Voltage:

-

380V

-

Power:

-

200-400kw

-

Dimension(L*W*H):

-

13.5m*4.5m*5.5m

-

Weight:

-

15000 kg

-

Warranty:

-

12 Months

-

Certification:

-

ce

-

Raw material:

-

Waste Paper, old carton box

-

Output paper:

-

kraft paper

-

Type:

-

Paper Producton Line

-

Application:

-

Paper Industry

-

Capacity:

-

150 t/d

-

drive way:

-

AC frequency converter section drive

-

control:

-

PLC

-

design:

-

according to clients' requirements

-

Name:

-

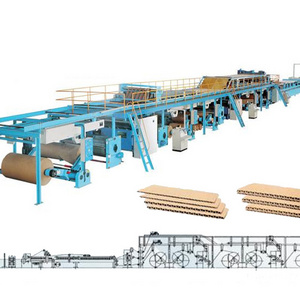

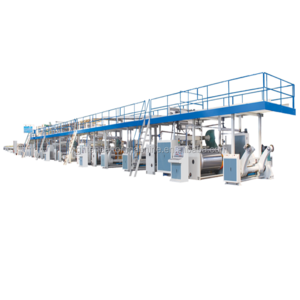

3 ply corrugated cardboard machine

Quick Details

-

Production Capacity:

-

Other

-

Product Type:

-

kraft paper

-

Processing Type:

-

3 ply corrugated cardboard machine

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Guangmao Machinery

-

Voltage:

-

380V

-

Power:

-

200-400kw

-

Dimension(L*W*H):

-

13.5m*4.5m*5.5m

-

Weight:

-

15000 kg

-

Warranty:

-

12 Months

-

Certification:

-

ce

-

Raw material:

-

Waste Paper, old carton box

-

Output paper:

-

kraft paper

-

Type:

-

Paper Producton Line

-

Application:

-

Paper Industry

-

Capacity:

-

150 t/d

-

drive way:

-

AC frequency converter section drive

-

control:

-

PLC

-

design:

-

according to clients' requirements

-

Name:

-

3 ply corrugated cardboard machine

automatic used corrugated carton box making machine 3 ply corrugated cardboard machine

This machine can use waste paper, old carton box as material to make kraft paper, testliner paper, fluting paper, capacity is 150 ton/day, final product is kraft paper roll. It includes following sections:

1. pulp making production line

2. paper making production line

3. paper processing section

4. boiler section

5. hot steam recycling system

6. installation tools

7. pipe, valve, flange, fittings

automatic used corrugated carton box making machine 3 ply corrugated cardboard machine

1. raw material: waste paper, old carton box, wood, cotton stalk etc.

2. output paper: kraft paper, corrugated paper, testliner paper, fluting paper.

3. capacity: 150 tons per day

4. net paper width: 3200mm

5. paper thickness: 80-300 g/m²

6. design speed: 300m/min

7. working speed: 250-280m/min

8. width of wire: 3600mm

9. rail gauge: 4100mm

10. drive&control system: Alternating current, frequency conversion, speed regulation, section drive.

kindly send us inquiry with the following information:

(1) the raw material you use? -waste paper/old carton box/ wood/ straw/cotton stalk etc.

(2) the finish product you want? -kraft paper/corrugated cardboard paper/testliner etc.

(3) the production capacity? -____ton/day

(4) the paper grammage you require? -____g/m²

(5) the paper width you require? -787mm/1092mm/1575mm/1760mm/1880mm/2100mm/2400mm/2640mm/3200mm/4400mm etc.

|

Packaging

|

|

|

|

Packaging Details

|

1. Fixed all the movable parts with plastic films.

2. Polystyrene foam plate wrapped around. 3. Wrapped with tighted plastic films several circles. 4. Fixed machine on the fumigated plywood pallet with iron wire. 5. Wrapped with wooden board around and nailed on. 6. Packaging according to your requirements. |

|

|

|

|

|

|

|

|

|

|

Delivery

|

|

|

|

Delivery Details

|

1. Delivery of the machinery can be by truck, by air, by train or by sea, which depends on the availability and convinence.

2. Delivery time will be within 40 days after first payment. 3. Accepted Delivery Terms: FOB, CFR, CIF, EXW, DDP, Express Delivery 4. Accepted Payment Type: T/T, L/C, Credit Card,Western Union, Cash 5. Nearest Port: QINGDAO, TIAN JIN |

|

|

|

|

|

|

|

|

|

Brief introduction to Zhengzhou Guangmao Machinery Co. Ltd. (OEM):

Founded in 1982, Zhengzhou Guangmao Machinery Co. Ltd. is a professional paper machinery manufacturer that specialized in manufacturing and exporting paper machine over the past 30 years.

Our products are all ISO9001:2000 and CE qualified, and have been exported to more than 30 countries. Our high quality products and perfect service have won customers' praise and more and more orders.

Business scope:

Various pulp making machines;

Various paper making machines;

Various paper processing machines;

Various spare parts.

Technology strength:

One professional technician team of 116 engineers and 12 experts;

32 years rich practice experience.

One innovation research team, always follow the advanced technology of Finland, Denmark and Italy;

Skilled and careful workers.

Company scale:

Four branch factories;

One International Trade Department;

Total area is 96,000 square meters.

Our market:

our machines sells well in more than 30 countries and regions, such as Russia, Indonesia, Uzbekistan, Tajikstan, Nigeria, Uganda, Pakistan, Egypt, Bhutan, Fiji, Brazil, Paraguay, Syria, Libya, Turkey, Canada etc. High quality and perfect service have reserved customers' praise and more orders. we have established good strategic cooperation with local distributor.

automatic used corrugated carton box making machine 3 ply corrugated cardboard machine

1.Why we choose your company?

(1)more than 30 years experience of manufacture paper machine and pulp making machine;

(2)professional engineer team ensure latest and best design;

(3)professional project manager ensure perfect service for whole procedure,such as quotation preparation,arrange shipment,customs clearance;

2.How to visit your factory and what is visiting schedule?

(1)Our company located in ZHENGZHOU city, HeNan province,

From Beijing to our city,it will take 1.5hours by flight or 3 hours by high speed train;

From Guangzhou to our city,it will take 2 hours and 20minutes by flight or 6.5hours by high speed train;

From Shanghai to our city,it will take 2hours by flight or 7hours by high speed train;

(2)after you confirm visiting plan,please inform us,we will arrange picking up and also booking hotel for you;

(3)welcome to visit our factory,you can check our factory facility,machine manufacturing ability,machine quality,we will also show you same working machine,you can check working performance and get necessary information of whole project,this can help you know well about this project;

3.How about technical service?

(1)we will send engineer to check your land condition and make precise design of whole factory;

(2)we will send engineers to make installation for you,after installation,they will teach your workers how to operation,maintain machine and also how to make paper;

(3)if you need,we can also keep some engineer working for you until you completely know well about machine;