- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Guang Mao Machinery

-

Voltage:

-

380V three phase

-

Dimension(L*W*H):

-

13.5m*4.5m*5.5m

-

Weight:

-

15 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

capacity:

-

30 T/D

-

Product name:

-

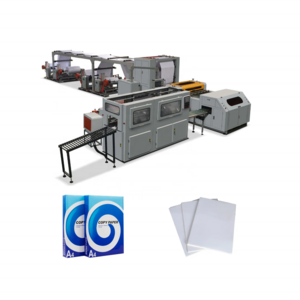

A4 Paper Machine

-

Function:

-

Slitting Rewinding JUMBO Paper Roll

-

Application:

-

Paper Industry

-

Usage:

-

Paper Making Mill

-

Color:

-

Optional Color

-

Model:

-

1760 Mm

-

Material:

-

Stainless Steel 304

-

Output paper:

-

A4/A3 Paper Copy Paper

Quick Details

-

Type:

-

paper making machine

-

Production Capacity:

-

30t/d

-

Max. workable width:

-

1880mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Guang Mao Machinery

-

Voltage:

-

380V three phase

-

Dimension(L*W*H):

-

13.5m*4.5m*5.5m

-

Weight:

-

15 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

capacity:

-

30 T/D

-

Product name:

-

A4 Paper Machine

-

Function:

-

Slitting Rewinding JUMBO Paper Roll

-

Application:

-

Paper Industry

-

Usage:

-

Paper Making Mill

-

Color:

-

Optional Color

-

Model:

-

1760 Mm

-

Material:

-

Stainless Steel 304

-

Output paper:

-

A4/A3 Paper Copy Paper

| Hot selling 1880mm writing paper / notebook paper / printing paper / copy paper / newsprint paper making Machine, raw material: waste paper | |||||

| I. Technical parameters: | |||||

| Raw material: | |||||

| output paper style: writting paper; | |||||

| Capacity:30 T/D; | |||||

| Output paper weight: 50-80g/m2; | |||||

| net paper width: 1880mm; | |||||

| Width of wire: 2250mm | |||||

| Rail gauge: 2700 mm | |||||

| Drive way: Motors with AC frequency converter & adjustable speed. Processing transmission | |||||

| Work speed: 60m/min | |||||

| Work speed: 80m/min | |||||

| II. paper machine part: | |||||

| (I). Description of paper making line | |||||

| 1. fourdrinier part: wire length is 13m. | |||||

| 2. Pre-press part: Ø400mm x 2250mm x 2700mm rubber roll 1 pc, Ø450mm x 2250mm x 2700mm stone roll 1 pc. | |||||

| 3. Main press part: Ø550mm x 2250mm x 2700mm stone roll 1 pc,Ø500mm x 2250mm x 2700mm rubber roll 1 pc. | |||||

| 4. Dryer part: Ø1500mm x 2250mm x 2700mm alloy dryer can 10pcs | |||||

| 5. Calender machine: 1 set, bottom roller: Ø400mm x 2250mm x 2700mm, upper roller:Ø380mm x 2250mm x 2700mm | |||||

| 6. Reeling machine: 1 set | |||||

| 7. Driving & control part: Equipped with 500 reducer, Motors with AC frequency convertor & adjustable speed, processing transmission. | |||||

| III. pulp making line | |||||

| IV. Hot water recycling system | |||||

| V. Waste water recycling system. | |||||

| VI. Boiler |

General view of white notebook paper making machine:

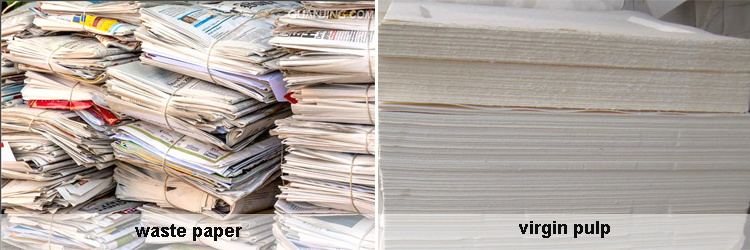

Raw material for making notebook paper: waste paper, virgin pulp.

Simplified notebook paper making process:

CAD drawing for notebook paper making machine: fourdrinier wire part, press part, dryer part, sizing machine, calender, reeling part.

Paper making machinery spare parts: cylinder mould, couch roll, net cage, dryer can, touch roll, exhaust hood, draught fan, air compressor, vacuum suction box.

Pulp making equipments: hydrapulper, pulp pump, vibrating screen, inclined screen, high & low consistency desander, thruster, fiber separator, pulp washing machine.

Finished paper product: jumbo roll white paper, notebook paper, newsprint paper, copy printing paper etc.

VII. Why choose us?We have the following advantages:

(1)Excellent characters of Zhengzhou Guangmao fluting paper manufacturing machine, paper mill, paper recycling machine price

1.high speed;

2.saving power;

3.good quality;

4.stable working;

5.competitive price;

6.high production capacity;

7.automaticlly;

8.exquisite technology;

9.can design according to your request.

2)Perfect service:

1. Technical consultation;

2. Project evaluation;

3. Detailed design of factory;

4. Installing and testing the whole production line;

5. Training engineers and workers;

6. Supplying spare parts for long time.