- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Glasino

-

Voltage:

-

380V/50/60HZ

-

Power:

-

360KW

-

Dimension(L*W*H):

-

14000x3700x900mm

-

Weight:

-

20000 kg

-

Marketing Type:

-

glass processing machine

-

Product name:

-

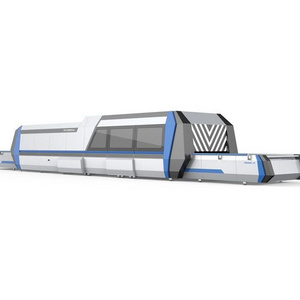

2130 2030 Glass Tempering Oven Tempered Glass Making Machine

-

Application:

-

Architectures Furniture Household Appliance

-

Max glass size:

-

2100*3000mm

-

Motor:

-

Sevro Motor

Quick Details

-

Machine Type:

-

Glass Tempering Furnace

-

Glass Thickness:

-

4-19mm

-

Production Capacity:

-

100%

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Glasino

-

Voltage:

-

380V/50/60HZ

-

Power:

-

360KW

-

Dimension(L*W*H):

-

14000x3700x900mm

-

Weight:

-

20000 kg

-

Marketing Type:

-

glass processing machine

-

Product name:

-

2130 2030 Glass Tempering Oven Tempered Glass Making Machine

-

Application:

-

Architectures Furniture Household Appliance

-

Max glass size:

-

2100*3000mm

-

Motor:

-

Sevro Motor

2130 2030 Glass Tempering Oven Tempered Glass Making Machine

Product Description

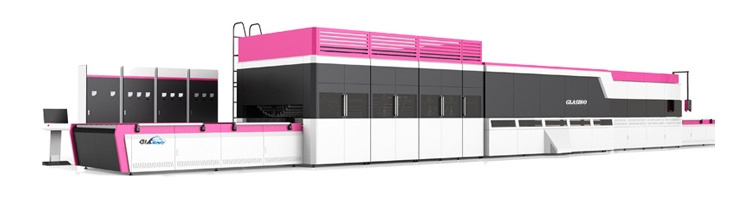

Glasino CNC

flat glass tempering furnaces are mainly used to produce glass for photovoltaic, household electrical appliance,

Building glass, home applicant glass, decoration glass, Low-E glass, furniture glass, etc

etc.

Product Paramenters

|

Model

|

Max loading size

(mm) |

Min size

(mm) |

Thickness

(mm) |

Output

(m²/h) |

Installed capacity

(KVA) |

|

AT-TA1225

|

1250×2500

|

100×250

|

3-19

|

53

|

200

|

|

AT-TA1636

|

1600×3660

|

100×250

|

3-19

|

91

|

400

|

|

AT-TA2036

|

2000×3660

|

100×250

|

4-19

|

126

|

500

|

|

AT-TA2436

|

2440×3660

|

100×300

|

4-25

|

152

|

630

|

|

AT-TA2442

|

2440×4200

|

100×300

|

4-25

|

173

|

630

|

|

AT-TA2450

|

2440×5000

|

100×300

|

4-25

|

202

|

800

|

|

AT-TA2460

|

2440×6000

|

100×300

|

4-25

|

245

|

1000

|

|

AT-TA2842

|

2850×4200

|

200×350

|

5-25

|

213

|

800

|

|

AT-TA2850

|

2850×5000

|

200×350

|

5-25

|

247

|

1000

|

|

AT-TA2860

|

2850×6000

|

200×350

|

5-25

|

301

|

1000

|

|

AT-TA3050

|

3000×5000

|

200×400

|

5-25

|

267

|

1000

|

|

AT-TA3060

|

3000×6000

|

200×400

|

5-25

|

321

|

1250

|

|

AT-TA3350

|

3300×5000

|

200×400

|

5-25

|

300

|

1000

|

|

AT-TA3360

|

3300×6000

|

200×400

|

5-25

|

352

|

1250

|

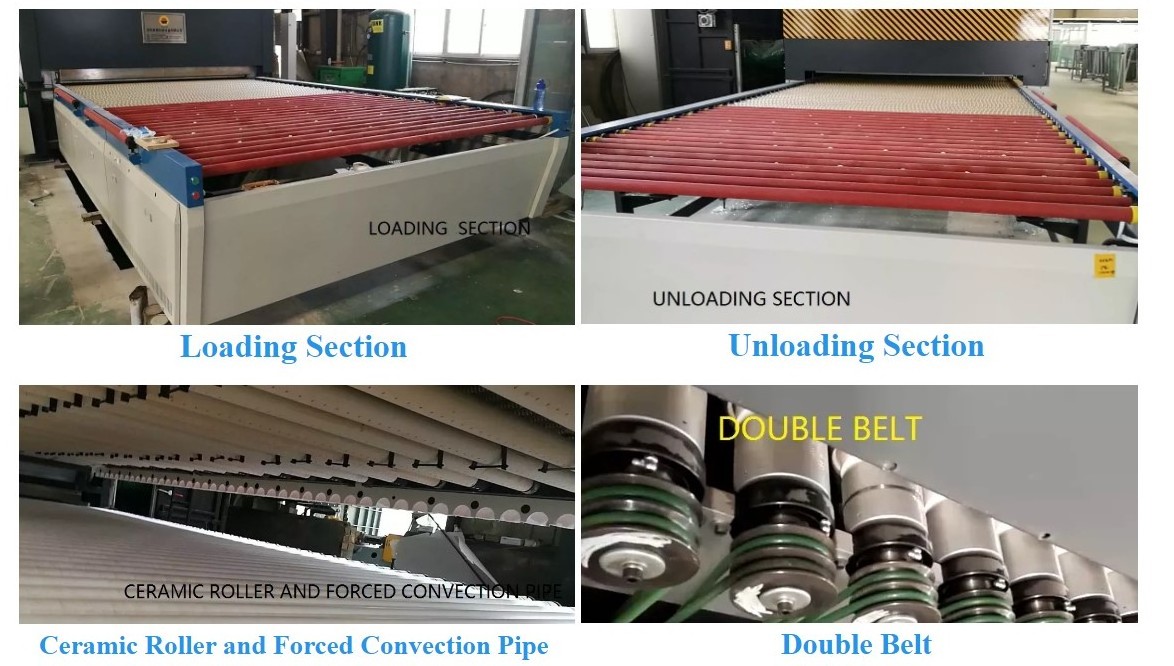

Advantages

1. Man-machine operation interface of intelligent control system

2. temperature control template accurate fine response speed fast inhibition rate is very high

3. The furnace door adopts the advanced guillotine type up and down design

4. high resistance deformation open and close freely

5. The synchronous o-belt is designed with two grooves

6. The heating section is more stable in reciprocating and online replacement is efficient and convenient

Warranty: one year

Machine commissioning and training:

Send engineers to buyer’s factory for machine set up, commissioning and also train the workers how to use the machine.

Aftersales service:

Life time techical and parts support.

On port techcial training or problem solving when necessary

Working Samples

Packing & Delivery

Loading container

Hot Searches