- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

10000 ml

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

vfine

-

Year:

-

New

-

Voltage:

-

According to customer country

-

Dimension(L*W*H):

-

6700*2050*2500mm

-

Hollow part volume:

-

5l-10l

-

Clamping Force (kN):

-

65000

-

Weight (KG):

-

8000 KG

-

After-sales Service Provided:

-

Provided

Quick Details

-

Neck Diameter(mm):

-

38 mm

-

Max.Bottle Diameter(mm):

-

105 mm

-

Max.Bottle Height(mm):

-

330 mm

-

Bottle Volume(ml):

-

10000 ml

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

vfine

-

Year:

-

New

-

Voltage:

-

According to customer country

-

Dimension(L*W*H):

-

6700*2050*2500mm

-

Hollow part volume:

-

5l-10l

-

Clamping Force (kN):

-

65000

-

Weight (KG):

-

8000 KG

-

After-sales Service Provided:

-

Provided

Product Overview

5l to 10l big size big capacity bottle blow molding machine

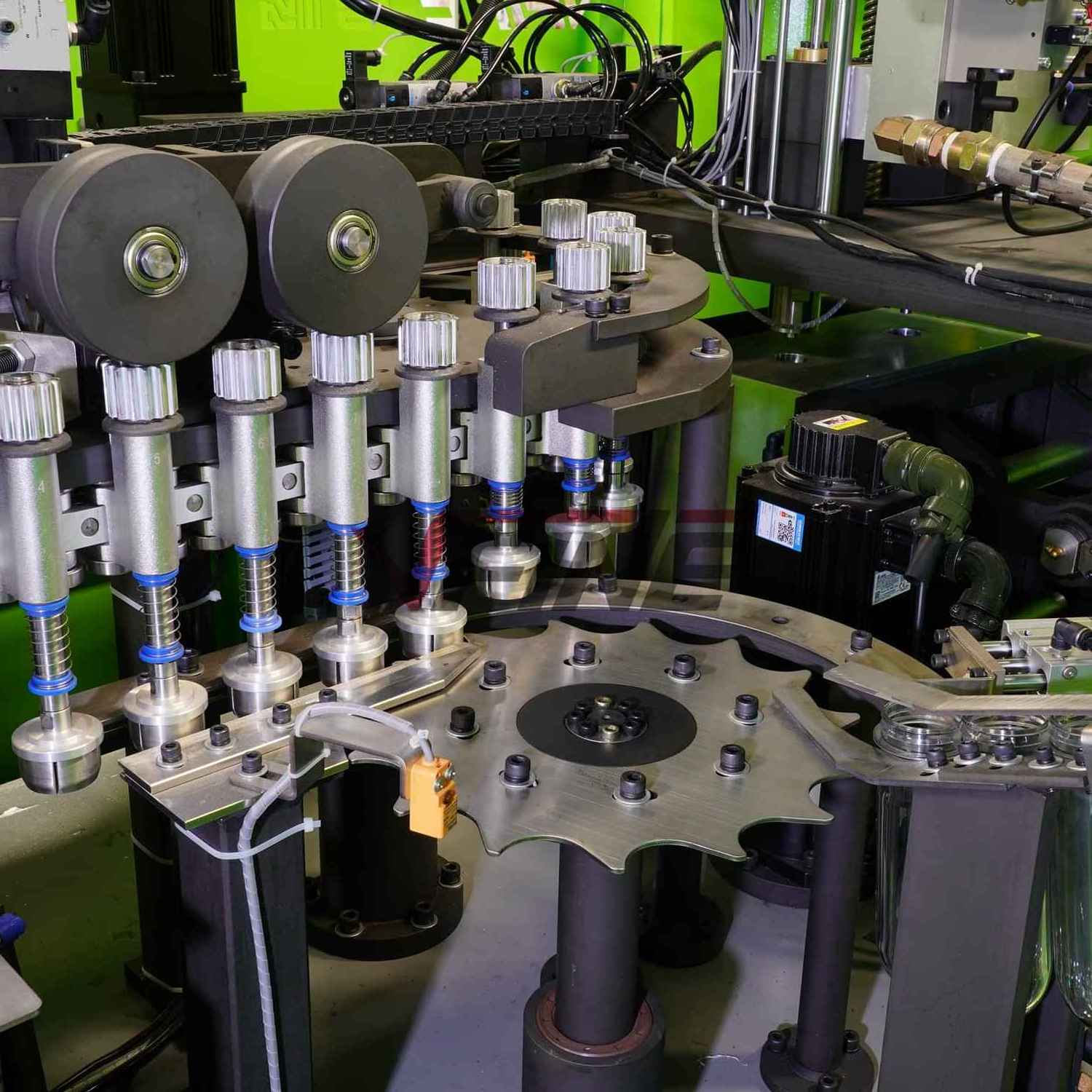

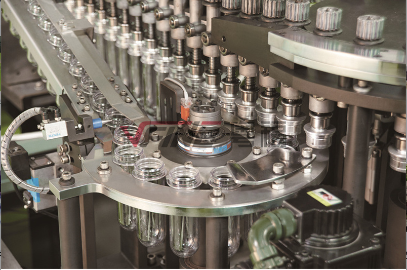

1. 10 liters pet bottle blowing machine YF-L3GLE

3-cavity, linear stretch blowing molding machine

Output: 2400-3500bph

PET bottle Volume range: 5L-10L

3-cavity, linear stretch blowing molding machine

Output: 2400-3500bph

PET bottle Volume range: 5L-10L

2) Application Scope:

Suitable for big capacity containers with a capacity range of 5L-10L, water bottles, beer tanks, edible oil bottles, detergent

tanks, condiment bottles, etc.

Suitable for big capacity containers with a capacity range of 5L-10L, water bottles, beer tanks, edible oil bottles, detergent

tanks, condiment bottles, etc.

FEATURES AT A GLANCE

* Energy efficient, flexible

The single chamber production capacity of the equipment is not less than 2000 bottles/hour, and the efficiency is high; the equipment combines the advantages of the rotary machine and the linear machine, with a high energy utilization rate and simple and convenient operation

* Fast mold change

Drawer-type mold locking structure, easy and quick mold change, no more than 30 minutes to change the mold

*

The whole machine frame and clamping plates are annealed, and the plane and hole processing are completed at one time in the CNC machining center to ensure that the machine frame and template are accurate, non-deformed, and durable.

* Powerful cooling system to ensure that the thin-walled preform neck bottles and light-weight bottles are not deformed.

* Powerful cooling system to ensure that the thin-walled preform neck bottles and light-weight bottles are not deformed.

1. Save energy :

The preform heating and blowing are on separated section, so that it can save the waiting time of each unit. The preforms are heated intensively, as the rotary machine heating type, improve the heating efficiency. Meanwhile, the high pressure air can saved by air recycling system, for the pre-blow or low pressure air supply, save energy.

2. Save space:

The infeeding system is inside the machine, the heating structure save the preform pitch distance, save the space.

3. High efficiency:

We improve about 20% output, in the situation of low down the machine energy consumption, improve the overall energy utilization.

4. Infeeding system:

The infeeding system is in single channel with less sensors for better infeeding.

The preform heating and blowing are on separated section, so that it can save the waiting time of each unit. The preforms are heated intensively, as the rotary machine heating type, improve the heating efficiency. Meanwhile, the high pressure air can saved by air recycling system, for the pre-blow or low pressure air supply, save energy.

2. Save space:

The infeeding system is inside the machine, the heating structure save the preform pitch distance, save the space.

3. High efficiency:

We improve about 20% output, in the situation of low down the machine energy consumption, improve the overall energy utilization.

4. Infeeding system:

The infeeding system is in single channel with less sensors for better infeeding.

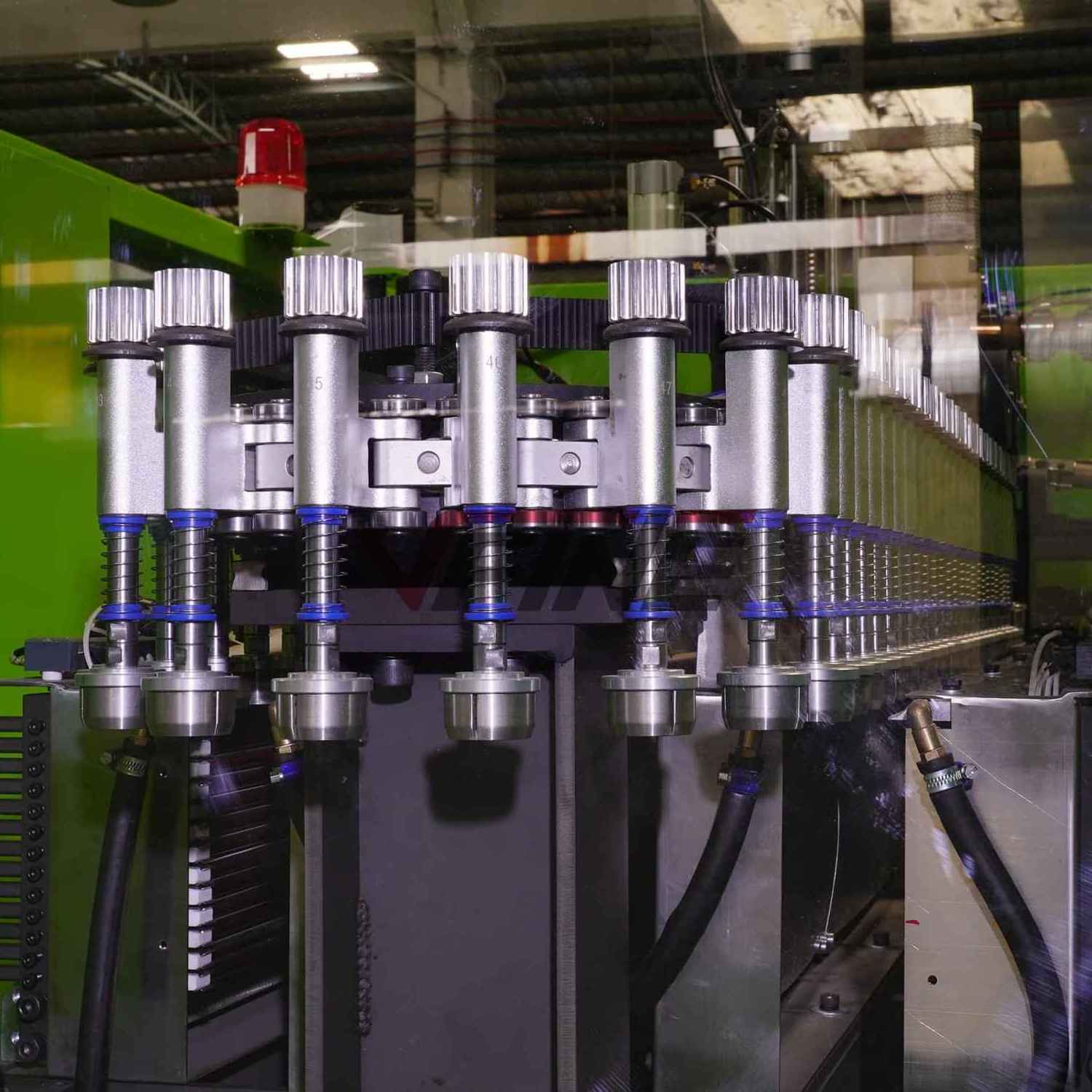

5. Heating system:

Preforms are heated intensively, the cooling device and the cross ventilation protect the preform neck from out of shape, improve the energy utilization, and heating efficiency.

6. Transfer unit: The variable pitch device is controlled by servo for stable and accurate transferring.

7. Clamping unit: The clamping unit is controlled by servo motor to ensure the synchronization, stable running and precise location.

8. High pressure air recycle system: The high pressure air recycle system save the high pressure to the tank, reduce the noise and save energy lost.

Preforms are heated intensively, the cooling device and the cross ventilation protect the preform neck from out of shape, improve the energy utilization, and heating efficiency.

6. Transfer unit: The variable pitch device is controlled by servo for stable and accurate transferring.

7. Clamping unit: The clamping unit is controlled by servo motor to ensure the synchronization, stable running and precise location.

8. High pressure air recycle system: The high pressure air recycle system save the high pressure to the tank, reduce the noise and save energy lost.

PRODUCT SPECIFICATIONS

|

item

|

big size bottle blow molding machine

|

|

machine model

|

YF-L3GLE

|

|

voltage

|

customizable

|

|

CAVITY NUMBER

|

3

|

|

Bottle size range

|

5L-10L

|

|

machine output

|

2400-3500BPH

|

|

machine size

|

6700*2050*2500MM

|

|

machine weight

|

8000KG

|

|

application scope

|

water, CSD, juice, cooking oil, wine, tea / energy drink,etc.

|

Hot Searches