- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

3824500000

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Biaoyuan

-

Model Number:

-

BY702

-

Type:

-

cement Mortar

Quick Details

-

CAS No.:

-

3824500000

-

Other Names:

-

Tile adhesive

-

MF:

-

Mixture

-

EINECS No.:

-

3824500000

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Biaoyuan

-

Model Number:

-

BY702

-

Type:

-

cement Mortar

Flexible adhesive/Paste the strong light brick binder/Flexible adhesive made of china

BiaoYuan Polymer modified cement based adhesive for fixing tiles to a variety of substrates , The product sets in 40 minutes and can accept light foot traffic in 3 hours at 90 degrees centigrade.

BiaoYuan cement based tile adhesive is suitable for fixing a variety of floor and wall tiles such as ceramics, slate, quarries, porcelain, vitrified, semi vitrified, limestone, terrazzo and mosaics to a variety of surfaces without an admix. When set, the adhesive is water resistant and is suitable for use in swimming pools.

1. Has strong cohesion force. Reduce the common phenomenon of tiles detaching and peeling when pasted by Portland cement.

2. Be premixed and produced, the product is stable, water and used, to protect the construction environment.

3. Has strong water retention, no need to dip tiles and wet walls, thin construction, easy operation, to reduce material consumption and building load.

4. Has good flexibility to resist effectively the destruction of various stresses.

5. Has special formula to avoid completely the common phenomenon of tiles cracking, detaching and peeling by Portland cement.

6. It is no-toxic, no-radiation, no smell and environmental.

7. Has special formula to prevent the flow with too much southbound crash, easier construction.

It is used to fix porcelain tiles, marbles, natural granites, natural stones, travertine,pool tiles and pieces, and non-slip tiles of middle sized (up to 60x60cm size for the wall and any size for the floor).

suitable to bond the following types of tile:

A):Ceramic, extruded and earthenware tiles

B): Low absorption ceramic tiles, which have poor adhesion to traditional tile

adhesives

C):Concrete and mortar

D): Bricks

E):Plaster (with primer)

F):Plasterboard, fibre cement

G):Existing tiled substrates

Coverage:

1.Use 3*3mm notched trowel,approx.1.5-1.8kg/m2

2.Use 6*6mm notched trowel,approx.2.8-3.0kg/m2

(The above dosage are recommened for the even substrate)

|

Surface drying time(Hr) |

≤5 |

|

|

Cohesive strength |

standard state (Mpa) |

≥0.6 |

|

Freeze-thaw cycle (Mpa) |

≥0.4 |

|

|

Alkali resistance (48hr) |

No change |

|

|

Water resistance (96hr) |

No change |

|

|

Using level (kg/ m²) |

1-1.5 |

|

|

color |

White and g rey |

|

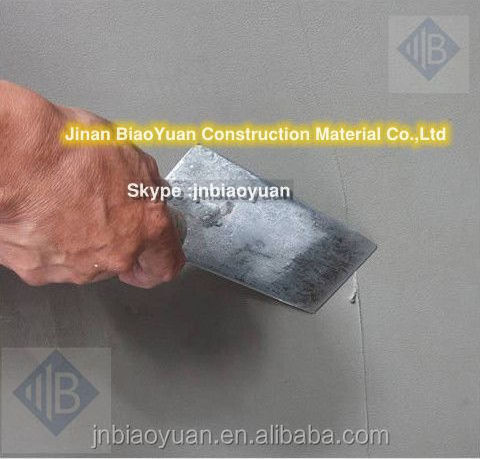

A: Primary treatment

Primary surface should be smooth solid, and fully dry, no sand, crack, bump inequality defects; no dust traces of oil and dirt. So, when the surface is rough or raised, application of trowels to its eradication, in order to deal with smooth surface.

B:Open the packing bags :

Cleaning benefits to cut off the dust, keep clean, open the package, with electric blender into uniform, no powder paste, mortar to be standing ten minutes after stirring once again increases the strength. The note, with the shovel to leave no droplet pulp scraping ideal condition.

C:Large area construction:

With a brush dipped in water, swipe the back of the tile, then wipe with a toothed blade to about one cubic meter of powder, then rub the pressure on the tile can be.