- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/660V/6KV/10KV

-

Dimension(L*W*H):

-

1730*1050*1480 mm

-

Weight:

-

1700KG

-

Air capacity:

-

3-7.5 m3/min

-

Product name:

-

RM37 permanent magnet variable frequency air compressor

-

Working handling capacity:

-

3-7.5 m3/min

-

Working pressure:

-

8 bar/115psi

-

Working voltage:

-

380V/660V/6KV/10KV

-

Cooling method:

-

Air cooling

-

Keywords:

-

Variable frequency air compressor

-

Working Power:

-

37 KW

-

Outlet valves:

-

G2''

-

MOQ:

-

1 Set

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Blurbly, Blurbly

-

Model Number:

-

RM37

-

Voltage:

-

380V/660V/6KV/10KV

-

Dimension(L*W*H):

-

1730*1050*1480 mm

-

Weight:

-

1700KG

-

Air capacity:

-

3-7.5 m3/min

-

Product name:

-

RM37 permanent magnet variable frequency air compressor

-

Working handling capacity:

-

3-7.5 m3/min

-

Working pressure:

-

8 bar/115psi

-

Working voltage:

-

380V/660V/6KV/10KV

-

Cooling method:

-

Air cooling

-

Keywords:

-

Variable frequency air compressor

-

Working Power:

-

37 KW

-

Outlet valves:

-

G2''

-

MOQ:

-

1 Set

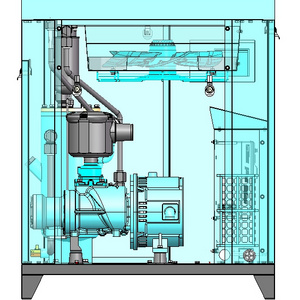

Product display

Product parameters

|

Model

|

RM37

|

|

Compressor type

|

Two stage permanent magnet variable frequency air compressor

|

|

Air end brand

|

Baosi/ODM

|

|

Working power

|

37 KW

|

|

Working handling capacity

|

3-7.5 m3/min

|

|

Working pressure

|

8 bar

|

|

Outlet valves

|

G2"

|

|

Weight

|

1700 KG

|

|

Dimension(L*W*H)

|

1730*1050*1480 mm

|

Advantages of permanent magnet variable frequency air compressor

1.High efficiency, environmental protection and energy saving.

At full load, the permanent magnet motor provides maximum gas volume with minimum energy consumption.When the load rate of permanent magnet variable frequency air compressor is less than 20%, the operation efficiency of 95% is maintained continuously, and the energy efficiency is achieved. Compared with fixed frequency air compressor, energy saving more than 39.7%. Compared with the general frequency conversion air compressor, environmental protection and energy saving 10%.

2.Long life and ultra durable.

The permanent magnet variable frequency air compressor chooses permanent magnet synchronous motor to drive the screw head, which has no magnetic loss at 120℃ and has a service life of ten years. Its screw head and motor use a spindle bearing, without the drive belt, shaft coupling, transmission system efficiency of 100%. The motor has no

rolling bearing, and the hidden trouble caused by the motor rolling bearing is removed.

3.Saving maintenance costs.

The volume of the permanent magnet motor is 1/2 smaller than the general three-phase motor head, the weight is 1/3 lighter, and the entire mechanical specifications are smaller. The screw head of permanent magnet variable frequency air compressor is 1/2 smaller than the general head, and the lubricating oil required for each maintenance is about 50% of the general screw air compressor, and the maintenance cost is greatly saved.

Hot Searches