- Product Details

- {{item.text}}

Quick Details

-

Coil Number:

-

AUTOTRANSFORMER

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

YUANGUANG

-

Model Number:

-

HSSP-8000/11

-

Tap changer:

-

NLTC/OLTC

-

Cooling type:

-

OFWF

-

High voltage range:

-

6-11kV

-

Rated power range:

-

630-8000kVA

-

Connection Symbol:

-

Dd0 Dy11

-

Windings material:

-

Copper

-

Iron core:

-

Silicon sheet

-

Standards:

-

IEC,GB,ANSI

-

Transformer:

-

Electric furnace transformer

-

Losses:

-

Low losses

Quick Details

-

Usage:

-

Power

-

Phase:

-

Three

-

Coil Structure:

-

TOROIDAL

-

Coil Number:

-

AUTOTRANSFORMER

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

YUANGUANG

-

Model Number:

-

HSSP-8000/11

-

Tap changer:

-

NLTC/OLTC

-

Cooling type:

-

OFWF

-

High voltage range:

-

6-11kV

-

Rated power range:

-

630-8000kVA

-

Connection Symbol:

-

Dd0 Dy11

-

Windings material:

-

Copper

-

Iron core:

-

Silicon sheet

-

Standards:

-

IEC,GB,ANSI

-

Transformer:

-

Electric furnace transformer

-

Losses:

-

Low losses

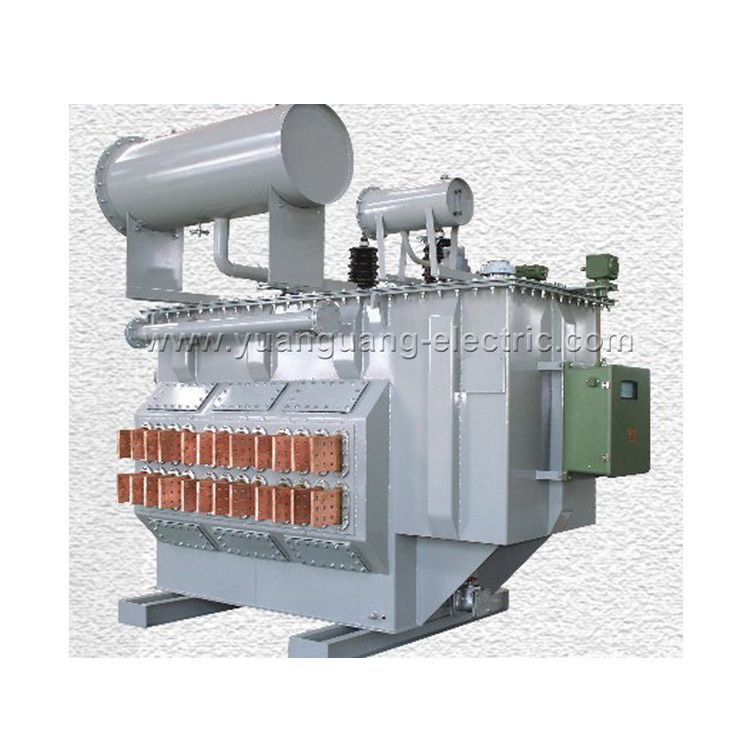

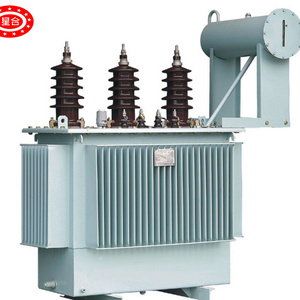

1.Pictures Of Electric furnace transformer

2.Descriptions Of Electric furnace transformer

| furnace transformer electric arc furnace transformer electric transformer | |

| 1 | Furnace transformers are separated with normal power transformer with its characteristic of massive secondary currents. |

| 2 | Arc furnace transformers used for steel-smelting |

| 3 | including load ratio voltage regulator type, no-load voltage regulator type,and built-in reactor type |

| 4 | Blast furnace transformers used for semlting of iron alloy, silicides, calcium carbide |

| 5 | single phase, three phase, load ratio voltage regulator and no-load voltage regulator |

| 6 | All are energy-saving products with low power loss. |

| 7 | Furnace transformers cooling modes are self-cooling mode, forced water cooling mode. |

5 . Technical Parameters Of Transformer

Arc furnace transformers Main Technical Parameters for HSSPZ, HSSP, HSSPK, HJSSP, HJSSPZ Series

6kV-11kV Level Arc furnace transformer:

| Rated power (kVA) | Primary voltage (kV) | Secondary Step Voltage (v) | Rated Secondary Current (A) | Connection symbol | Short-Circuit impedance (%) | Type of taping | No-load loss(W) | On-load loss(W) |

|

630

300 1000 |

6

6.3 10 10.5 11 |

200

170 116 98 |

1819

2609 2887 |

Dd0

Dy11 |

S-9

7-S |

no-load tap changing | 2.4 | 8.6 |

| 2.7 | 11.0 | |||||||

| 3.1 | 14.0 | |||||||

|

1250

1600 2000 |

210

180 121 104 |

3437

4399 5499 |

3.6 | 17.5 | ||||

| 4.1 | 22.0 | |||||||

| 4.6 | 27.0 | |||||||

|

2500

3150 |

220

190 127 110 |

6561

8267 |

5.2 | 32.0 | ||||

| 6.0 | 39.0 | |||||||

|

4000

5000 |

240

210 130 121 |

9623

12023 |

7.6 | 46.0 | ||||

| 9.4 | 54.0 | |||||||

|

6300

3000 |

260

240 210 139 |

13900

17765 |

11.3 | 63.0 | ||||

| 15.0 | 74.0 |

6.Certifications And Workshop Of Product

7.Function And Features Of Product

| On-load-tap-changing Electric Arc Furnace Transformer | ||

| 1)Low loss | 4) High efficiency | 7)Pretty outline and compact structure |

| 2)Low noise | 5) Easy maintenance | 8)100% guaranteed no leakage |

| 3) Operation reliability | 6) Low partial discharge | 9)Strong mechanical strength and short-circuit with |

| Electric Arc Furnace Transformer Introduction to Products | |

| 1 | Furnace transformers are separated with normal power transformer with its characteristic of massive secondary currents. |

| 2 | Arc furnace transformers used for steel-smelting |

| 3 | including load ratio voltage regulator type, no-load voltage regulator type,and built-in reactor type |

| 4 | Furnace transformers used for semlting of iron alloy, silicides, calcium carbide |

| 5 | Load ratio voltage regulator and no-load voltage regulator |

| 6 | All are energy-saving products with low power loss. |

| 7 | Transformers cooling modes are self-cooling mode, forced water cooling mode. |

8. Installation And Packing Of Product

9. Our Best Service For You

| 1. | Pre sale service |

| a. | make technical solution |

| b. | send quotation, technical data sheet and drawing |

| c. | prepare power transmission plan, testing plan,and shipment plan |

| 2. | In sale service |

| a. | supervise the manufacturing schedule totally in accordance with the plan |

| b. | send photos to customer during every manufacturing process(hold point) |

| c. | inform the customer one week before testinng. |

| 3. | After sale service |

| a. | installation and commissioning, training the workers |

| b. | quick response within 12 hours any time |

| c. | provide 12 months gurantee period normally. |