- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

GS-mach

-

Voltage:

-

Customized

-

Power:

-

250kw

-

Dimension(L*W*H):

-

50*5*15 m

-

Weight:

-

8690 kg

-

Name:

-

Stone Paper Extrusion Line

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Raw material:

-

PE+Calcium Carbonate

-

Working speed:

-

600r/min

-

Finished Products:

-

Stone Paper Roll

-

Advantage:

-

Easy Operation Auto Counting

-

Capacity:

-

1000-7000 PCS/hour (9 Inch Round Dish)

-

Certification:

-

CE/TUV/ISO9001

Quick Details

-

Production Capacity:

-

200 m/min

-

Product Type:

-

Composite paper machine

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

GS-mach

-

Voltage:

-

Customized

-

Power:

-

250kw

-

Dimension(L*W*H):

-

50*5*15 m

-

Weight:

-

8690 kg

-

Name:

-

Stone Paper Extrusion Line

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Raw material:

-

PE+Calcium Carbonate

-

Working speed:

-

600r/min

-

Finished Products:

-

Stone Paper Roll

-

Advantage:

-

Easy Operation Auto Counting

-

Capacity:

-

1000-7000 PCS/hour (9 Inch Round Dish)

-

Certification:

-

CE/TUV/ISO9001

Now Recommended

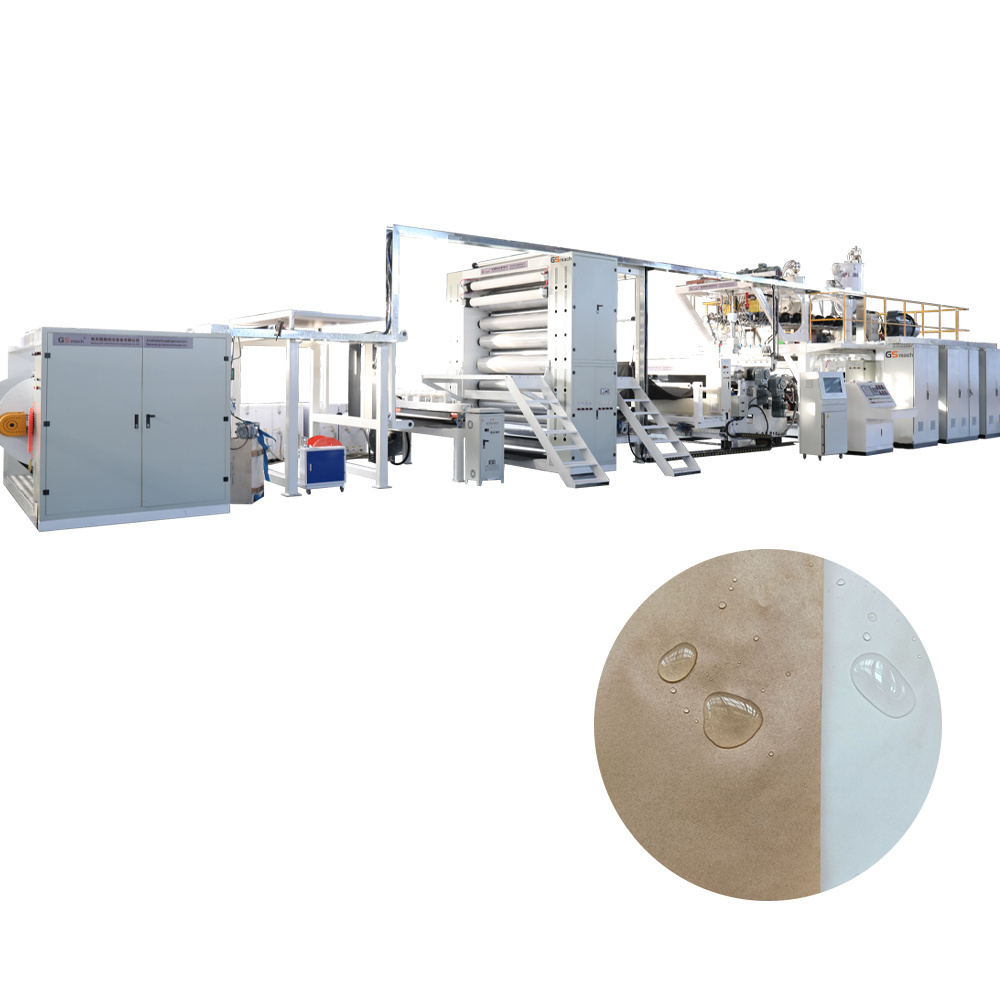

GS-mach Eco-riendly Biodegradable Stone Paper Making Machine for notebooks wallpaper wrapping paper magazines

Machine Presentation

Stone Paper machine

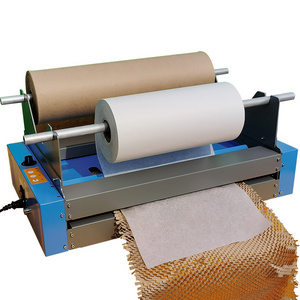

Principle:

Stone paper is limestone mineral resources as the main raw material (calcium carbonate content 70-80%), polymer as auxiliary material (content 20-30%), stone paper production equipment using composite flow/calendering production process: batching, blending, extrusion to produce masterbatch, and then through extrusion, calendering, stretching, cooling, surface treatment, coating, slitter winding is the base paper.

Equipment advantages:

Stone paper production process is simple, high yield, low energy consumption; Do not use plant fiber, do not cut down trees, can save a lot of wood, protect the natural ecology; Do not need to add strong acid, strong alkali, bleach and other chemical raw materials, do not discharge waste water, waste residue and toxic and harmful gases, belong to green products.

Equipment Parameter

Constitute

: extrusion part----casting part----corona part----winding part----electric control part and other five parts.

Among them, the mold part and the extrusion part can be freely combined according to the requirements of users, so as to meet the different needs of the market to the maximum extent.

|

Type

|

Power(kw)

|

Wdith(mm)

|

Thickness

|

Q(T/Y)

|

|

GS-LY1600

|

800

|

1400-1600

|

80-450

|

7000

|

Machine Composition

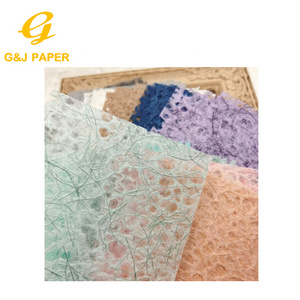

Application

Stone paper refers to a new material between paper and plastic, which can replace some of the traditional functional paper, professional paper, and most of the traditional plastic packaging. It has the characteristics of low cost and controllable degradation, which can save a lot of costs for users and will not produce pollution.

1, it can be used in disposable consumables, such as: garbage bags, food bags, shopping bags, lunch boxes, raincoats, dust cover and other places.

2, can also be used on self-paper, such as: printing paper, writing paper, printing paper, cigarette paper, newspapers and other places.

3, can also be used in the construction of decoration, generally common is wallpaper.

4, for the industrial field also has a certain involvement, such as: cement bags, rice bags, clothing bags, etc.

5, some paper used in special cases can also be used to stone paper, such as: field, mine operation paper.

Factory Introduction

Hot Searches