- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Power:

-

5.5KW

-

Dimension(L*W*H):

-

2950*1320*1500mm

-

Weight:

-

3000 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

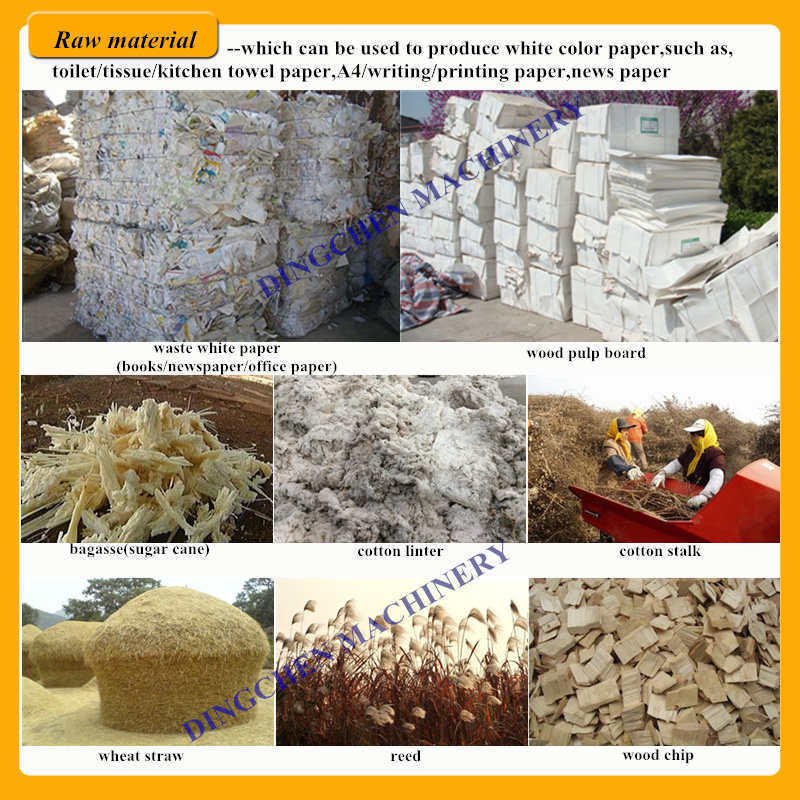

raw material:

-

waste paper or wood pulp

-

output paper:

-

kraft paper/corrugated paper/toilet paper/serviette paper

-

colour:

-

as you like

-

Type:

-

small toilet paper making machine

-

Model Number:

-

small toilet paper making machine

-

Certification:

-

iso9001

-

packing:

-

safrty packing

-

After Warranty Service:

-

Online support

Quick Details

-

Production Capacity:

-

0.8-1T/D

-

Place of Origin:

-

Henan, China, Henan China (Mainland)

-

Brand Name:

-

Dingchen

-

Voltage:

-

220V/380V

-

Power:

-

5.5KW

-

Dimension(L*W*H):

-

2950*1320*1500mm

-

Weight:

-

3000 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

raw material:

-

waste paper or wood pulp

-

output paper:

-

kraft paper/corrugated paper/toilet paper/serviette paper

-

colour:

-

as you like

-

Type:

-

small toilet paper making machine

-

Model Number:

-

small toilet paper making machine

-

Certification:

-

iso9001

-

packing:

-

safrty packing

-

After Warranty Service:

-

Online support

Small waste paper recycling machine 787mm fully automatic toilet paper machine

I. Application of Toilet Paper Machine:

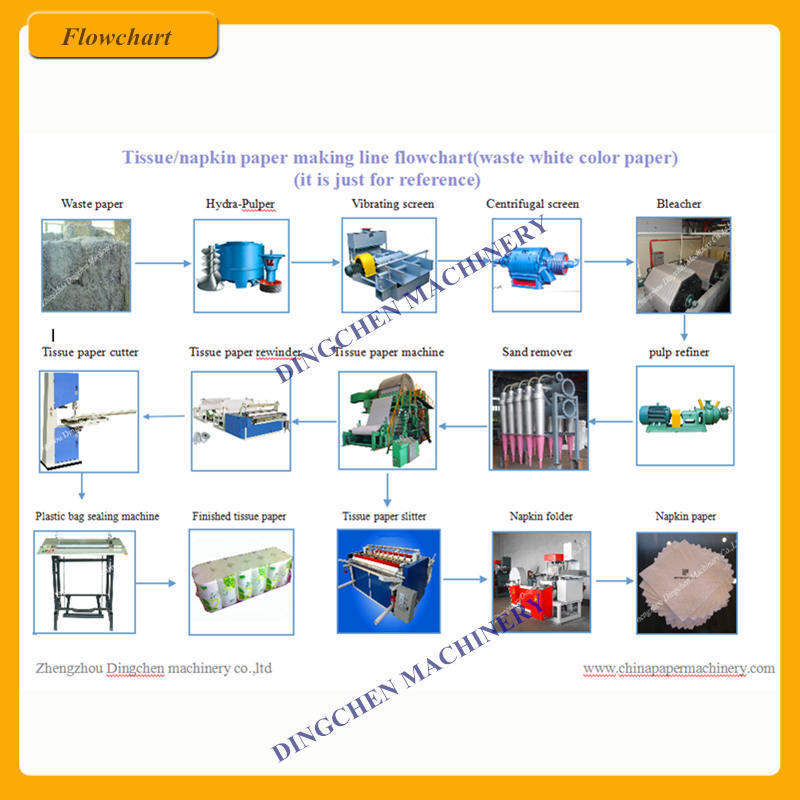

Using all kinds of waste paper as the raw material to make new pulp or using virgin pulp as raw material directly, and then produce best quality toilet or tissue paper, it can also to make napkin papers by further processing. This small model use lowest investment and small land to get fast profit.

II.Main Technical Parameters of 787mm Toilet Paper Machine

1.Paper type: medium and high-grade toilet paper,napkin and tissue paper

2.Raw materials: waste paper, wood pulp or wheat straw

3. Gram weight: 13--30g/ m2

4. Paper width: 787mm

5. Cylinder width: 1100mm

6. Design speed: 100m/min

7. Working speed: 60m/min

8.The rail gauge:1300mm

9.The capacity: 0.8-1T/D

10.Pressure type:pneumatic pressure

11.Drive model: frequency control and substep transmission

12.Machine design: square box, left or right position

13.Hanging pulp type: upside down

III.structure and characteristics of 787mm toilet paper machine:

1. cylinder section:Φ1000mm×1100mm stainless steel cylinder mould 1set, Φ260mm×1100mm couch roll 1set,coated by rubber,rubber shore hardness 38°C±2.

2.dryer section:Φ1250mm×1100mm cast iron alloy dyer can 1 set, Φ300mm×1100mm touch roll 1set,1group scraper knife. rubber shore hardness 90°C±2.Mechanical pressure device.

3.paper cutting section: 787mm slitting machine1set .

4.drive and control section: Alternating current , speed control , section drive

IV. Flow chart of 787mm toilet paper machine

Main equipments:

|

No. |

Equipment |

Quantity(set) |

|

1 |

1575mm tissue machine |

1 |

|

2 |

Dryer exhaust hood(double layer) |

1 |

|

3 |

Φ1000 axial-flow fan |

1 |

|

4 |

Sealing type pressure cylinder vat |

1 |

|

5 |

Model 15 roots vacuum pulp |

1 |

|

6 |

Suction box |

2 |

|

7 |

5m3 high consistency hydrapulper |

1 |

|

8 |

2m2 high frequency vibrating screen |

1 |

|

9 |

35m3 bleacher |

4 |

|

10 |

380 double-disc refining mill |

1 |

|

11 |

Φ700 impeller |

5 |

|

12 |

IS 750-100 desander pulp |

1 |

|

13 |

606 desander 5 pcs |

1 group |

|

14 |

Double-phase flow pump-100 |

6 |

|

15 |

Double-phase flow pump-150 |

4 |

|

16 |

1575 rewinding machine |

1 |

|

17 |

Paper cutter |

1 |

|

18 |

Air pump box |

1 |

|

19 |

Frequency conversion controller |

1 |

|

20 |

Whole station |

1 |

|

21 |

2T boiler |

1 |