- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

UAR

-

Liquid Flow Rate:

-

1.5 cbm/hr ~ 756 cbm/hr

-

Maximum Working Pressure:

-

2.75MPa

-

Weight:

-

5 KG

-

Dimension(L*W*H):

-

No more than 9m

-

Warranty:

-

1 year

-

Certification:

-

ce

-

Cooling capacity:

-

2.5~1000RT

-

Material:

-

Aluminum brass tube/ Nickel - Copper tube

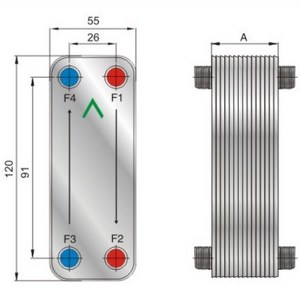

Quick Details

-

Structure:

-

Tube Heat Exchanger

-

Voltage:

-

220v/380v/customized

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

UAR

-

Liquid Flow Rate:

-

1.5 cbm/hr ~ 756 cbm/hr

-

Maximum Working Pressure:

-

2.75MPa

-

Weight:

-

5 KG

-

Dimension(L*W*H):

-

No more than 9m

-

Warranty:

-

1 year

-

Certification:

-

ce

-

Cooling capacity:

-

2.5~1000RT

-

Material:

-

Aluminum brass tube/ Nickel - Copper tube

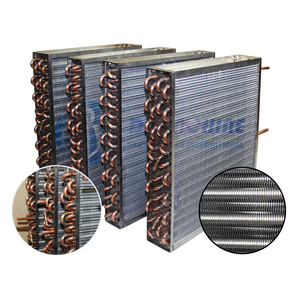

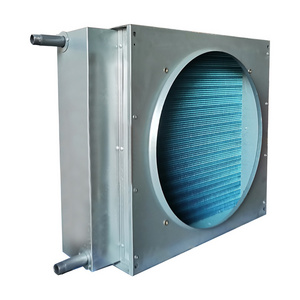

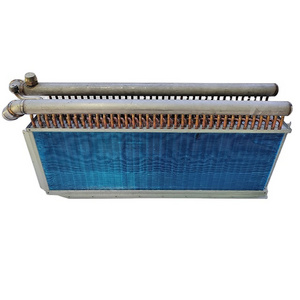

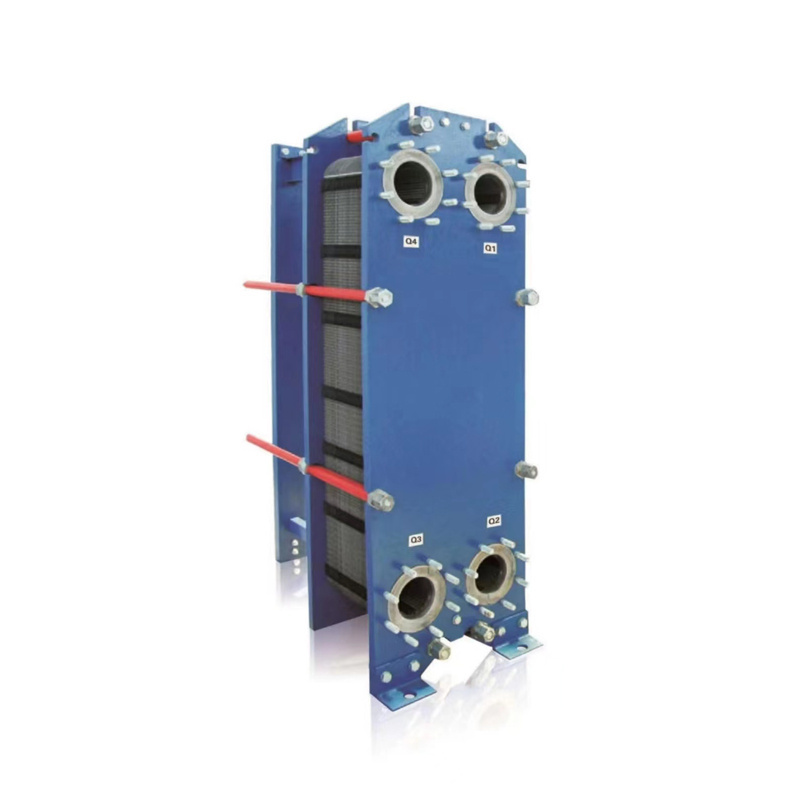

industrial titanium air to air shell and tube brazed plate water refrigeration equipment heat exchangers

Shell and tube heat exchanger manufacturer,

self-made from raw material metal sheet (Cutting, Rolling, Welding, X-ray, Exam Welding Leak, Outer Shell and Tube Sheet, Flange, Cover Ends)

, strict quality & cost control, national certified test center to ensure.

I) UAR Shell And Tube Heat Exchanger/ Condenser/ Evaporator Features

1. Internal & external enhanced groove, ensure high heat transfer efficiency;

2. Cooling capacity from 2.5RT~1000RT;

3. All self-made components, strict quality & cost control, inspected by our own lab and authorized third party before delivery;

4. 1 to 8 refrigerating circuits available, or as per special design;

5. Option for CE/ ASME certificate;

6. Stainless steel evaporator, titanium evaporator, flooded evaporator, spray falling film evaporator are available;

7. Knock down type heat exchanger and heat exchanger combination are available (option for condenser/ evaporator/ control box/ drier-filter/ oil sperator/ expansion valve assembly)

8. OEM business is welcome.

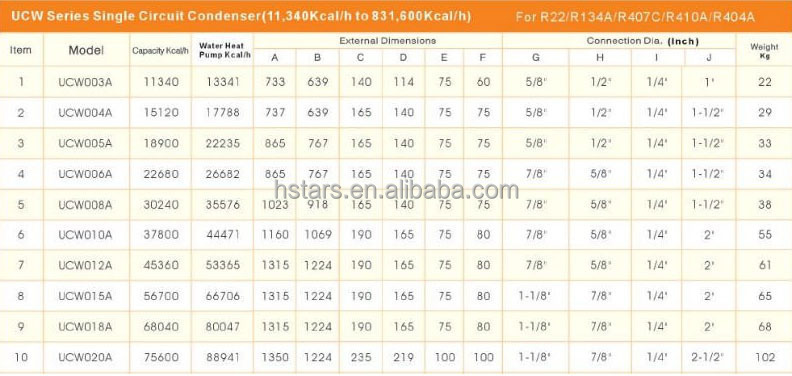

Condenser specification:

Evaporator specifications:

For more model and special requirements, please contact us for further information.

1)wooden case with assemble package

2) plateform with unassemble package

3) assemble package with EPE foma and bubble film

1,Wooden pallet base

2,With transparent package film well protect machine

3,For side go with buffer panel well protect machine during shipping period