- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

USEON

-

Voltage:

-

110V,220V,380V,460V

-

Power:

-

40KW

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

2000

-

Product name:

-

3LPE External Coating Line

-

Feature:

-

bear stripping, acid, alkali and ultraviolet radiation

-

Advantage:

-

high efficiency, energy saving and environment friendly

-

Usage:

-

oil, gas and water transportation

Quick Details

-

Machine Type:

-

3LPE steel pipe coating line, Coating Equipment

-

Marketing Type:

-

Hot Product

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

USEON

-

Voltage:

-

110V,220V,380V,460V

-

Power:

-

40KW

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

2000

-

Product name:

-

3LPE External Coating Line

-

Feature:

-

bear stripping, acid, alkali and ultraviolet radiation

-

Advantage:

-

high efficiency, energy saving and environment friendly

-

Usage:

-

oil, gas and water transportation

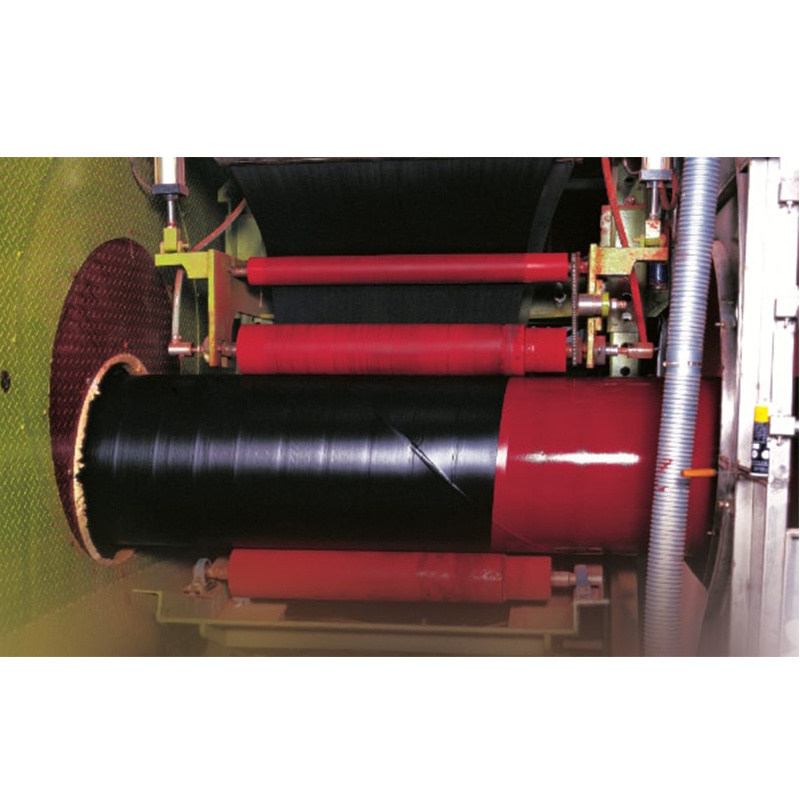

Products Description

The 3PE coating line for steel pipeline is a whole set of equipment which is the most advanced coating of the buried steel pipeline. This equipment represents the most advanced coating process being popular in the whole world.

By combining the FBE coating technology popular in North America and the PE/PP technology popular in Europe, this production line can coat pipes with single-layer FBE coat, double-layer FBE coat, double-layer PE coat, 3PE coat, 3PP coat and also is capable for coating concrete balancer pipe.

The pipes coated by this equipment have been broadly applied in oil, gas and water transportation . Such pipes have been applied for sub-oceanic pipeline. Supported by reasonable process control, such coated pipes boast high capability to bear stripping,acid, alkali and ultraviolet radiation . The pipes treated by 3PE coating process, boasting excellent performance, have beenhonored as “Permanent Anticorrosive System” in this industry.

This production line, equipped with many special equipment/devices and supported by several kinds of environment protection equipment/devices, can ensure the advantages including high efficiency, energy saving and environment friendly for coating production.

By combining the FBE coating technology popular in North America and the PE/PP technology popular in Europe, this production line can coat pipes with single-layer FBE coat, double-layer FBE coat, double-layer PE coat, 3PE coat, 3PP coat and also is capable for coating concrete balancer pipe.

The pipes coated by this equipment have been broadly applied in oil, gas and water transportation . Such pipes have been applied for sub-oceanic pipeline. Supported by reasonable process control, such coated pipes boast high capability to bear stripping,acid, alkali and ultraviolet radiation . The pipes treated by 3PE coating process, boasting excellent performance, have beenhonored as “Permanent Anticorrosive System” in this industry.

This production line, equipped with many special equipment/devices and supported by several kinds of environment protection equipment/devices, can ensure the advantages including high efficiency, energy saving and environment friendly for coating production.

|

Product Name

|

3LPE External Coating Line

|

|

Feature

|

Boast high capability to bear stripping, acid, alkali and ultraviolet radiation

|

|

Advantage

|

High efficiency, energy saving and environment friendly

|

|

Usage

|

This equipment have been broadly applied in oil, gas and water transportation

|

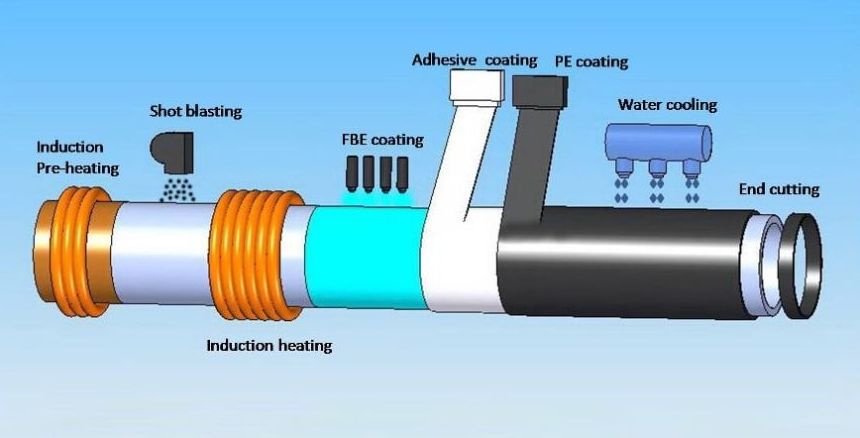

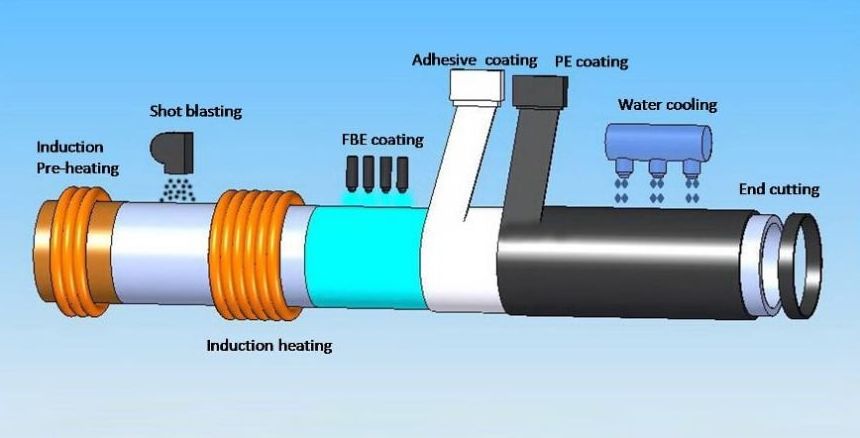

Flow chart of coating process

1) Inbound Rack and Conveyor

The pipe will be loaded by this unit. It consisted of inbound rack and convey system. All actions are driven by hydraulic system.The Main rack made of thick wall rectangle structure steel tube is to ensure convey stable and to meet the max heavy-load requirement of heavy pipe. Catch and release pipe is controlled by PLC automatically.

2) Induction Preheating

This unit is to heat up the pipe for better shot blast performance. The induction unit is middle frequency induction heater. The surface of pipe would be 50-60℃.

3) Shot Blast

Shot blast unit is to remove the dust, oil and moisture one the surface of the pipe. By this way, the coating performance would be better and longer lifetime.

4) Epoxy Coating

Special design of corona hi-voltage electrostatic powder spraying gun can meet the requirements of high temperature. Hi-voltage electrostatic generator can provide 100kV(DC) power. This ensures the high speed and high efficiency. Spraying gun made in Japan.Modular design is good for maintenance. Spraying room made of stainless steel, light inside. Powder recycling uses cyclone and cartridge. Material of cartridge is polyester fiber and micro holes aluminum foil composite material. This can eliminate electrostatic,can be washed by water.

5) Adhesive and PE coating

The adhesive will flow out from the hanger die to coat on the epoxy layer. It is could enhance the strength between PE layer andepoxy layer.

PE and adhesive layers would be laminated online.

PE and adhesive layers would be laminated online.

6) Water Cooling

After coating of adhesive and PE layers, the pipe will entry to the cooling room to cool down the coated pipe. The water is

circling.

The convey system can tilt automatically to empty the water inside during the cooling step. Also the catch pipe and release pipe action are automatically.

circling.

The convey system can tilt automatically to empty the water inside during the cooling step. Also the catch pipe and release pipe action are automatically.

7) Checking Platform

Now the pipe is ready for checking. This platform is for quality check and transfer the qualified pipe and unqualified pipe to

different zones.

different zones.

Recommend Products

Company Strength

Established in 2006, Useon has been focusing on polymer extrusion equipment and process technology. Our professional and aspiring team has made a number of milestones in designing machines for plastic processing.We are committed to providing advanced polymer extrusion equipment and total solutions for our customers. As the most qualified Chinese partner in polymer extrusion equipment,Useon continues to serve many Fortune 500 international group's. Assisting by educating our clients and averting potential troubles through our experience we can help in many facets.We can be reached via email, telephone, and fax. We are bilingual,easily accessible and readily available. Always glad to help you in your endeavors.

Certifications & Exhibition

Product packaging

FAQ

Q1:

Why choose us?

A1:15 years experience of machinery.

Q1: How long is the warranty?

A1:We can offer one-year warranty for the whole machine.

Q1: Is your product can be assured ?

A1:We can offer one-year warranty for the whole machine.

Q1: What makes you different with others?

A1:We have global branch offices, we can offer local service.

Q1: If we show you our layout of factory, can you help to design the whole process line?

A1:Yes, our professional engineers and technical employee can help you to arrange the layout and installation of

whole process line based on your requirement.

Q1: How long is the warranty?

A1:We can offer one-year warranty for the whole machine.

Q1: Is your product can be assured ?

A1:We can offer one-year warranty for the whole machine.

Q1: What makes you different with others?

A1:We have global branch offices, we can offer local service.

Q1: If we show you our layout of factory, can you help to design the whole process line?

A1:Yes, our professional engineers and technical employee can help you to arrange the layout and installation of

whole process line based on your requirement.

Hot Searches