- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Vinson

-

Dimension(L*W*H):

-

Cutomer's Request

-

Weight:

-

3 KG

-

Working Temperature Range:

-

30 - 850 ℃

-

Core Components:

-

immersion heater

-

Resistance wire:

-

Ni80Cr20, FeCrAl etc

-

Insulation:

-

High purity, compacted magnesium Oxide

-

Temperature resistance:

-

maximum 1000 centi degree

-

Diameter:

-

6mm, 6.5mm, 6mm, 10mm, 12mm(customized)

-

Length:

-

10mm to 6000mm(customized)

-

Wattage Density:

-

3-20w/c㎡

-

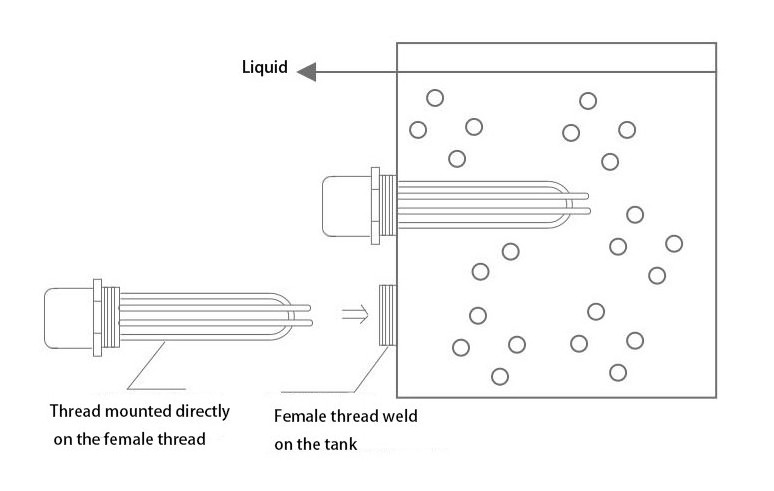

Screw Threads:

-

1", 1-1/4", 1-1/2", 2", 2-1/2"

-

Power tolerance:

-

-5%-0%

-

Application:

-

water or oil

Quick Details

-

Type:

-

Immersion Heater

-

Power Source:

-

Electric

-

Voltage:

-

12-480v(customized)

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Vinson

-

Dimension(L*W*H):

-

Cutomer's Request

-

Weight:

-

3 KG

-

Working Temperature Range:

-

30 - 850 ℃

-

Core Components:

-

immersion heater

-

Resistance wire:

-

Ni80Cr20, FeCrAl etc

-

Insulation:

-

High purity, compacted magnesium Oxide

-

Temperature resistance:

-

maximum 1000 centi degree

-

Diameter:

-

6mm, 6.5mm, 6mm, 10mm, 12mm(customized)

-

Length:

-

10mm to 6000mm(customized)

-

Wattage Density:

-

3-20w/c㎡

-

Screw Threads:

-

1", 1-1/4", 1-1/2", 2", 2-1/2"

-

Power tolerance:

-

-5%-0%

-

Application:

-

water or oil

220v 380v 3kw 6kw 9kw 12kw 15kw electric Water Heater Element DC immersion Tubular Heating Element with 1.5'' BSP/NPT

are welded or silver-brazed into a pipe or steel flange. Perfectly designed to be mounted in tanks and pressurized vessels, Vinson flange heaters are used for heating liquid mediums or other specific types of liquids, and for heating gases (water, oil, heat transfer fluid, and corrosive solutions).

|

Materials

|

Copper, steel, 316, 321, 347 stainless steel,

INCONEL and more |

|

Number Elements in Flanges

|

3, 6, 12,18, 27, 36 ,45 or more

|

|

Element Diameter

|

3, 6, 12,18, 27, 36 and 45

|

|

Immersion Lengths

|

up to 240 inches

|

Please consider the following factors in order to select the proper flange heater:

• Flange size and pressures

• Heating element watt density

• Length of your tank

• Sheath material (corrosive or non corrosive)

Temperature of the corrodent

Degree of aeration of exposed corrodent

Velocity of the corrodent

The following sections will help you select the best flange heater that will meet the requirements of your application.

|

APPLICATIONS

|

SHEATH MATERIAL

|

FLANGE MATERIAL

|

|

Clean water, Freeze protection, Hot water storage,Boiler and water heaters, Cooling towers,

Solutions not corrosive to copper |

Copper

|

Steel

|

|

Hot water , Steam boilers, Mildly corrosive solutions

(in rinse tanks, spray washers) |

Incoloy

|

Steel

|

|

Oils, Gases, Mildly corrosive liquids,Stagnant or heavy oils,

High temperature, low flow gas heating |

Steel

|

Steel

|

|

Process water, Soap and detergent solutions,Soluble cutting oils, Demineralized or deionized water

|

Stainless

|

Steel

|

|

Mildly corrosive solutions

|

Stainless

|

Stainless

|

|

Severe corrosive solutions, Demineralized water

|

Incoloy

|

Stainless

|

|

Light oil, Medium oil

|

Steel

|

Steel

|

|

Food equipment, Food equipment with cutout

|

Incoloy

|

Stainless

|

The key questions which need to be answered before selecting a tubular heating element are:

1.What wattage and voltage will be used?

2.What is the diameter and heated length required?

3.What's the heating medium? Water or Oil heating?

4.What is thread flange size?