- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

10000

Quick Details

-

Place of Origin:

-

Shandong, China

-

Marketing Type:

-

New Product 2022

-

Power (kW):

-

180

-

Weight (KG):

-

10000

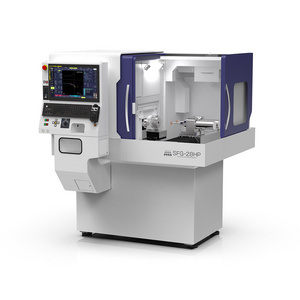

High-Speed Turbine blade Grinding machine

1. Mechanical structure:

1.1 The overall layout is a mobile cross-mop plate with excellent performance, and the main motion includes the rotary motion of the horizontal grinding wheel spindle,

The left and right longitudinal movement of the bench (X axis), the front and rear transverse motion of the mop (Z axis), the upper and down of the grinding body is v ertical lift movement (Y-axis).

1.2 The machine tool has good anti-vibration characteristics, precise motion characteristics, good structural rigidity and small thermal deformation characteristics;

The moving parts of the machine tool have good rigidity and high feed sensitivity. The X, Y and Z axes use "servo motor + ball wire rod" o f pure mechanical way.

1.3 X axis adopts double V sliding guide rail and achieves high precision through manual shoveling.

1.4 Y and Z axis pre - tighten precision linear roller guide rail, with high rigidity, precision positioning characteristics.

1.5 The three axis is driven by AC servo motor + ball wire rod, and the minimum blade capacity of the three axis is 0.001mm.

1.6 The lubrication system of the machine tool adopts the fixed-point quantitative oil supply mode, the lubricating oil tank belt pressure and liquid level detection, and the system alarm prompts refueling to ensure that the guide rail and wire of the machine tool do not lose oil.

1.7 The machine tool adopts full cover + moving door protection structure, which is convenient for the knife and has good waterproof effect.

2. Special grinding software:

2.1 Special man-machine picture grinding software, which can automatically grind, automatically trim, easy to learn and learn, reduce the skill requirements; rough grinding, semi-fine grinding, fine grinding and optical grinding can be provided to ensure the consistency of roughness and dimensional accuracy of workpiece grinding.

| Delivery time | 90-120 days |