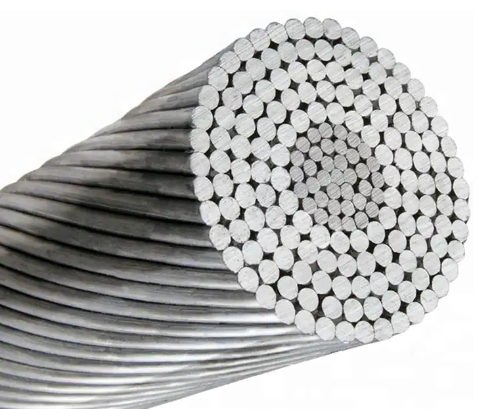

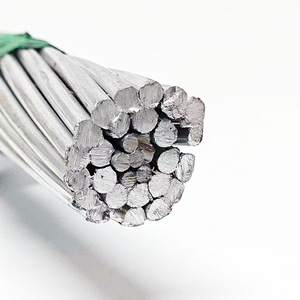

1. Anatomy of ACSR: Aluminum Conductor Core: The core of ACSR is made of high-purity aluminum, chosen for its excellent conductivity. This lightweight yet conductive material forms the primary path for the flow of electrical current.

Steel Reinforcement:

Stranded around the aluminum core is a layer of high-strength galvanized steel wires. This steel reinforcement not only enhances the mechanical strength of the conductor but also provides robust support against mechanical stresses.

2. Structural Design and Variants:

Stranding Configuration:

ACSR conductors come in various stranding configurations, with multiple aluminum and steel strands twisted together. The stranding pattern is carefully engineered to optimize both electrical conductivity and mechanical strength.

Variants for Specific Applications:

Different variants of ACSR are tailored for specific applications. Variations in the aluminum and steel content, as well as stranding designs, allow for customization based on the demands of the transmission environment.

3. Conductivity and Electrical Performance:

Optimized Electrical Conductivity:

The high conductivity of aluminum ensures efficient transmission of electrical energy, while the steel reinforcement provides structural integrity.

Temperature Rating:

ACSR is designed to withstand varying temperatures, maintaining its electrical performance even in extreme weather conditions.

4. Strength and Mechanical Resilience:

Load-Bearing Capabilities:

The steel component of ACSR contributes significantly to its load-bearing capabilities. This allows ACSR to span long distances between transmission towers without sagging excessively.

Resistance to Tension and Compression:

ACSR exhibits excellent resistance to both tension and compression forces, crucial for maintaining its structural integrity in the face of dynamic loads.

5. Applications Across Voltage Levels:

High Voltage Transmission:

ACSR finds widespread use in high voltage transmission lines, where its combination of high conductivity and mechanical strength is indispensable.

Distribution Networks:

While larger variants serve in transmission, smaller ACSR configurations are also employed in distribution networks, connecting substations to end-users.

6. ACSR in Environmental Conditions:

Corrosion Resistance:

The galvanized steel strands provide ACSR with robust corrosion resistance, making it suitable for installations in diverse environmental conditions, including coastal and industrial areas.

Ice Loading Considerations:

ACSR's structural design takes into account the potential for ice loading in colder climates, ensuring reliable performance even under such challenging circumstances.

7. Innovations and Advancements:

Composite Core Materials:

Ongoing research explores the use of advanced composite materials for the core of ACSR, aiming to enhance conductivity and reduce overall weight.

Smart Grid Integration:

ACSR is being integrated into smart grid systems, enabling real-time monitoring of its condition and performance. This facilitates proactive maintenance and contributes to the overall reliability of the power grid.

8. Environmental Impact and Sustainability:

Recyclability:

Both aluminum and steel components of ACSR are recyclable, aligning with sustainable practices in the power transmission industry.

Life Cycle Assessment:

Conducting a life cycle assessment of ACSR provides insights into its overall environmental impact, helping utilities make informed decisions about its use.

Standards

GB/T1179, IEC61089, ASTM B231, ASTM B399, BS215-1, BS3242, DIN48201, BS EN 50182 etc.

GB/T1179, IEC61089, ASTM B231, ASTM B399, BS215-1, BS3242, DIN48201, BS EN 50182 etc.