- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

New Product 2023

-

Wire size:

-

2 ~ 8 mm ( Hard wire max to 6mm )

-

Servo motor:

-

6 Axis

-

Wire feeding motor:

-

7.5KW

-

Optioanal:

-

Customize

-

Feeding Rollers:

-

6pcs x 120 x 25mm

-

Wire Decoiler:

-

Automatic, max 1000kgs

-

Wire Feeding Accurate:

-

Within 0.08mm at 100mm length

-

Advantage:

-

Multi Functions / Widely Usage.

-

Input voltage:

-

AC, 380V, 3 phase

-

After-sales Service Provided:

-

Online support, Spare parts

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Guang Jin CNC

-

Weight (KG):

-

5530

-

Marketing Type:

-

New Product 2023

-

Wire size:

-

2 ~ 8 mm ( Hard wire max to 6mm )

-

Servo motor:

-

6 Axis

-

Wire feeding motor:

-

7.5KW

-

Optioanal:

-

Customize

-

Feeding Rollers:

-

6pcs x 120 x 25mm

-

Wire Decoiler:

-

Automatic, max 1000kgs

-

Wire Feeding Accurate:

-

Within 0.08mm at 100mm length

-

Advantage:

-

Multi Functions / Widely Usage.

-

Input voltage:

-

AC, 380V, 3 phase

-

After-sales Service Provided:

-

Online support, Spare parts

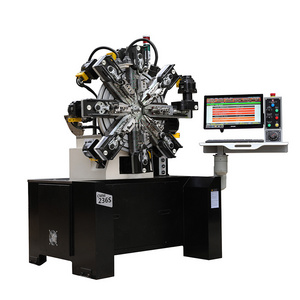

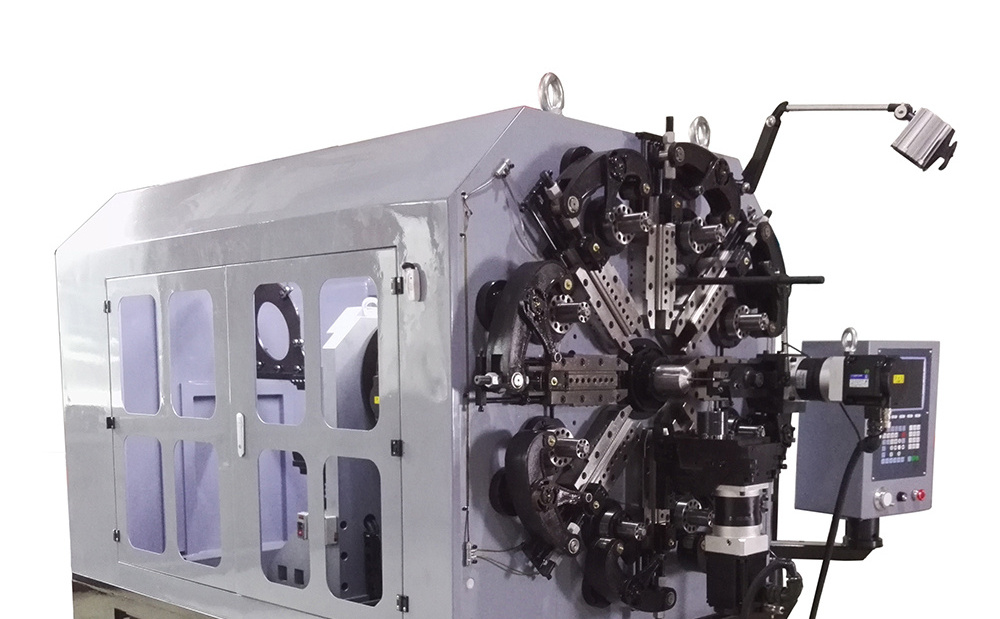

6 Axis 8mm CNC Industrial Spring Bending Machine Heavy Duty Spring Making Machinery Bed Sheet Hanger Maker

Model: GJ-60TR

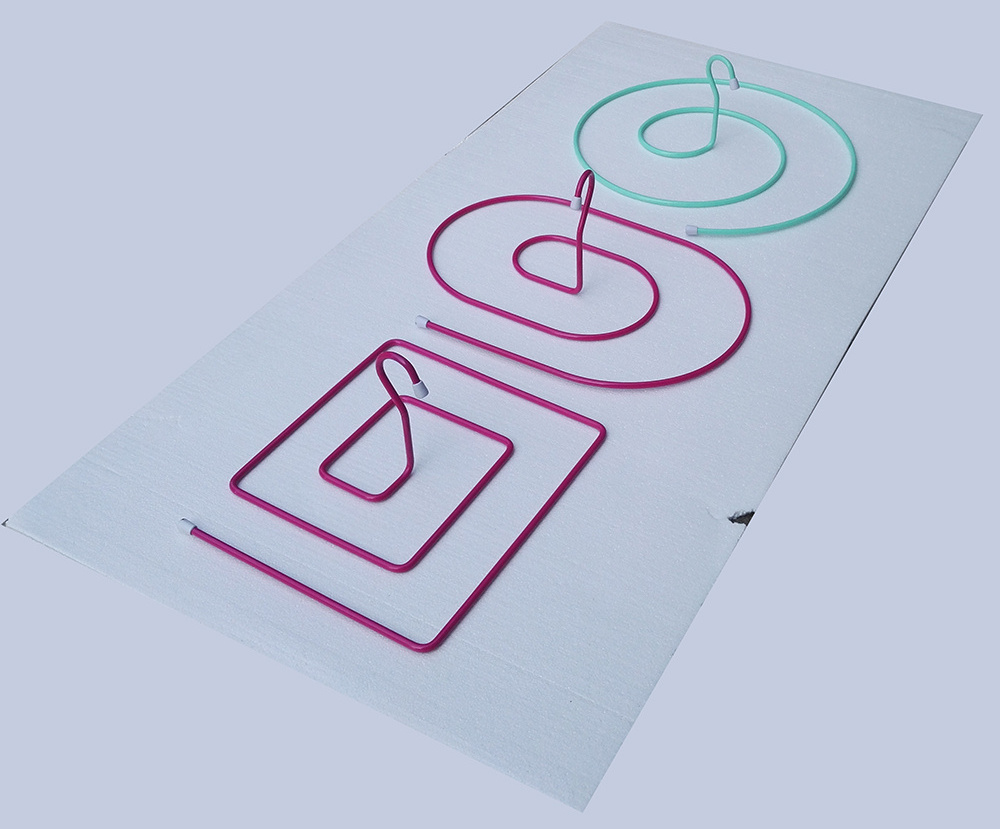

8mm sprial bed sheet hanger bending machine

quilt cover hook forming machine

Compression spring machine, CNC torsion spring machine, Spring making machine,Spring bending machine, Spring winding machine, Industrial spring forming machine, Car copper wire coiler, Car energy copper inductor making machinery

Specification Sheet:

6 Axis 7mm Wire Rotary S pring Forming M achin e

Model: GJ-60TR

|

Producing: vary types springs, wire forming / wire bending crafts, customized shapes |

|

|

Feeding Wire Size |

Φ3 - 7 mm hard wire |

|

Number of Axis |

6 axis (servo motors) |

|

Input / Power Supply |

380V, AC, 3 phase / Customized. |

|

Total Power / Work Consumption |

25.5KW / 6.5KW |

|

Control System |

Arcuchi, En / Cn, or customized 3 rd Lag. |

|

Program Saved |

Max 100 products. |

|

Wire Feeding Precision |

±0.04mm @ 100 mm |

|

Avg Producing Speed |

12 ~18 pcs per minute. |

|

Optional |

7 TH axis as Servo Scissor |

|

Wire Feeding Roller |

3 Pairs x (120 x 25 mm ) |

|

Wire Decoiler |

Max load: 800kg, Heavy duty. |

|

Full set machine space occupy |

WDH: 245x650x240cm |

|

Eexport Package |

2 CTN / 5530kgs/ 18.3CBM |

Sample testing Training

our machine series

Q: Are you manufacturer?

A: Yes, we are factory in making and selling vary type of spring machines to clients world wide with our own brand and trademark.

We have the direct export permit, with own Bank Accounts for: Euro / USD / RMB.

Q: What is your acceptable price term and payment term ?

A: We are flexible on them to meet with clients vary of conditions.

Most as FOB Shenzhen port, CIF Worldwide Main Port,

T/T as the mostly way, or pay by client

’

s China Partners.

Q: Why choose you? What is your difference from other Chinese supplier?

A 1 : We have specialized in this area for over 18 years.

A2: We will try react your demands within 12 minutes during 08:00 ~ 22:00

A3: I ’ m willing to find a professional solution for you with both efforts.

A4: Particular, if needed, we can provide 3 rd Language Manual: as Spanish, Portuguese, Russian

Q: What is the lead time?

A: For most of our machine models, it ’ s within 12 days.

Then sampling task some 2-4 days.

Q: Is the machine tested before shipment?

A: Mostly, it goes a 72 hours warm-up firstly, next to sampling verified, thirdly to go dispatch.

Q: How is the machine packed?

A: Over-Round protective film wrapped , then export non-solid wooden carton packed .

Q: What should I do if there is a problem during machine in using ?

A: 1. Take pictures of the screen, or record video of screen. Then send to our sales.

2. Arrange a online video talking.

3. Telling us the servo ’ s signal light, then get to know what kind of errors.

4. Take next actions as vary type of efforts.

Q: How can I get in contact with you?

Main Contact: Ms. Jenny Yang

Mobile / Wechat/W A : 86 - 13423161776 .

Skype: Jennyyang2006