- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

THD

-

Model Number:

-

GM103

-

Voltage:

-

220-240V/110-127V

-

Frequency:

-

50-60HZ

-

Arcing distance:

-

≥6mm

-

Duration of ignition:

-

10s

-

Duration of rekindling:

-

10s

-

Discharge energy:

-

≥4J

-

Discharge cycle:

-

≤400ms

-

Width:

-

≥12μs

-

Deferent high pressure:

-

≥15KV

-

Product name:

-

Oven parts electric pulse igniter for Gas oven

Quick Details

-

Material:

-

Plastic

-

Feature:

-

Sustainable

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

THD

-

Model Number:

-

GM103

-

Voltage:

-

220-240V/110-127V

-

Frequency:

-

50-60HZ

-

Arcing distance:

-

≥6mm

-

Duration of ignition:

-

10s

-

Duration of rekindling:

-

10s

-

Discharge energy:

-

≥4J

-

Discharge cycle:

-

≤400ms

-

Width:

-

≥12μs

-

Deferent high pressure:

-

≥15KV

-

Product name:

-

Oven parts electric pulse igniter for Gas oven

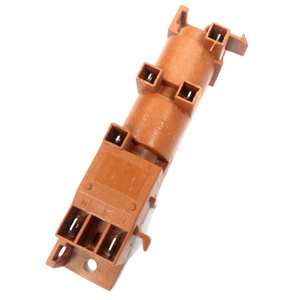

Product Name:

Oven parts electric pulse igniter for Gas oven GM103

Product Purpose

This product is mainly used for the ignition and control of industrial equipment with the energy of liquefied petroleum gas, natural gas and coal gas.

It is widely used in all kinds of gas burner, gas heater, gas stove, gas cooker, gas oven, gas furnace .

Features of pulse igniter:

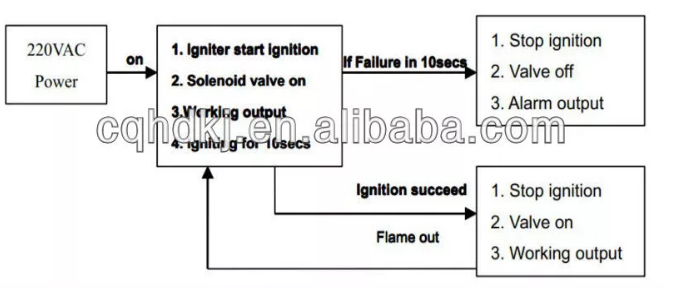

- Electric ignition or switching control ignition

- Ignition again automatically if fire went out accidentally.

- Automatic monitoring or photoelectric control. If the fire went out, it can give warning automatically.

- If it failed to ignite the gas or the fire went out accidentally, it can cut off the gas supply immediately.

- Technology of Single-chip and digital microcomputer

Working process

Technical Parameter of Oven parts electric pulse igniter for Gas oven GM103

|

No |

Items |

Quotas |

Remarks |

|

1 |

Rated operational voltage |

VAC |

|

|

2 |

Discharge frequency |

5 0HZ |

|

|

3 |

Arcing distance |

≥6mm |

|

|

4 |

Duration of ignition |

10s |

It can be adjusted according to your requirements |

|

5 |

Duration of rekindling |

10s |

|

|

6 |

Discharge energy |

≥4J |

|

|

7 |

Discharge cycle |

≤400ms |

|

|

8 |

Width |

≥12μs |

|

|

9 |

Deferent high pressure |

≥15KV |

|

Detail picture for Industrial oven ignition parts electric pulse igniter GM103

Application of Oven parts electric pulse igniter for Gas oven

Installation Precaution

1.Please refer to the ignition wiring method and the matters needing attention.

2.The power supply anode and negative must connect correctly, if not the result is: (1) as normal operation, but it will release high-voltage every few seconds and lead to ignition coil burned and shortened life span; (2) don’t be ignited, feedback to the alarm,and then the high-tension coil will be immediately burned.

3.The ground wire must be grounded. If not: (1) high-voltage ignition is weak; (2) high-voltage can lead to ignition coil burning.

4.High-voltage ignition wire and inductive wire can’t not fix mutual. If not, the induction IC and ignition coil will be burned.

5.Avoid large current in working place (e.g. spot welder, spot welding, high frequency, electrical equipment, and large current equipment ), as instantaneous current high or low and countercurrent will influence the ignition work.

6.High-voltage and inductive cable are not too long(the factory length id the best) as it will influnce the ignition and inductive work so that reduce the lifetime of ignition. Special note: the high-voltage and inductive cables can’t use ordinary wire.

7.Ignition needle part notice: (1) high-voltage ignition needle shall not touch the ground, that will affect ignition’s life; (2) Inductive needle which touch the ground would influnce inductive needle’s effect, also even destroy ignition.

8.Ignition needle high-pressure arcs distance is offen 3-5mm,not too wide to ignite and induct.

9.Power supply short circuit can also cause ignition short circuit.