- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

145*155*197cm

-

Weight:

-

200 KG

-

Drilling Diameter:

-

100-240mm

-

Drilling Depth:

-

Max 120m

-

Product name:

-

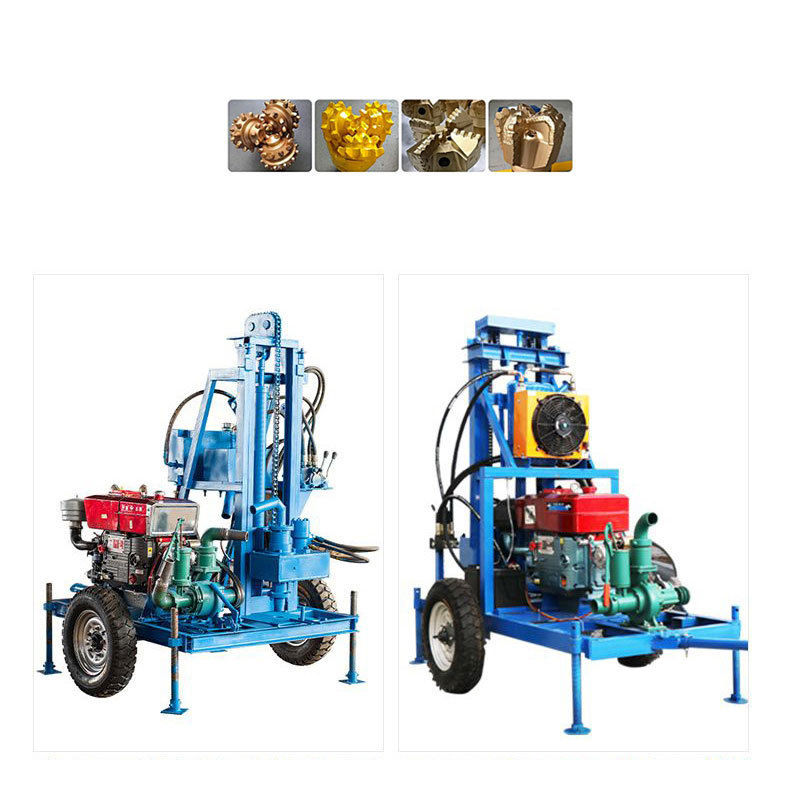

water drilling rig

-

Engine:

-

Electric Diesel

-

Keyword:

-

Drilliing Rig

-

Function:

-

Easy Operate Small Drilling Machine

-

Application:

-

Water Wells Rock Drill Rig

-

Drill pipe replacement method:

-

Automatic lever release, manual lever change

-

Drilling method:

-

Rotary cutting

-

Drilling diameter::

-

100mm-240mm

-

Lifting force:

-

1000KG

-

Drill pipe length:

-

1.5m

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Gondor

-

Voltage:

-

220V/380V/diesel

-

Dimension(L*W*H):

-

145*155*197cm

-

Weight:

-

200 KG

-

Drilling Diameter:

-

100-240mm

-

Drilling Depth:

-

Max 120m

-

Product name:

-

water drilling rig

-

Engine:

-

Electric Diesel

-

Keyword:

-

Drilliing Rig

-

Function:

-

Easy Operate Small Drilling Machine

-

Application:

-

Water Wells Rock Drill Rig

-

Drill pipe replacement method:

-

Automatic lever release, manual lever change

-

Drilling method:

-

Rotary cutting

-

Drilling diameter::

-

100mm-240mm

-

Lifting force:

-

1000KG

-

Drill pipe length:

-

1.5m

Product Description

Introduction:

Water well drilling rig is suitable for soil layers, quicksand layers and a small amount of rock layers. It is mainly used for

drilling civil draft wells, irrigation wells, ground source heat pump air conditioning wells, dewatering wells, small foundation piles, and sound measuring pipes.

Features:

1. Lightweight and compact.

2. Fast hole forming speed.

3. Low noise.

4. Mechanical automatic loading and unloading of drill pipe, easy to move.

5. The power output torque is large, the opening diameter can reach 50 cm, and the deep well can be drilled to 150 meters.

2. Fast hole forming speed.

3. Low noise.

4. Mechanical automatic loading and unloading of drill pipe, easy to move.

5. The power output torque is large, the opening diameter can reach 50 cm, and the deep well can be drilled to 150 meters.

Product Paramenters

|

Parameter:

|

|

|

Model

|

GD-240

|

|

Drill pipe diameter

|

51mm

|

|

Dimension

|

145*155*197cm

|

|

Drill pipe length

|

1.5m

|

|

Weight

|

200kg

|

|

Drill pipe replacement method

|

Automatic lever release, manual lever change

|

|

Drilling method

|

Rotary cutting

|

|

Drilling depth

|

120m

|

|

Drilling diameter

|

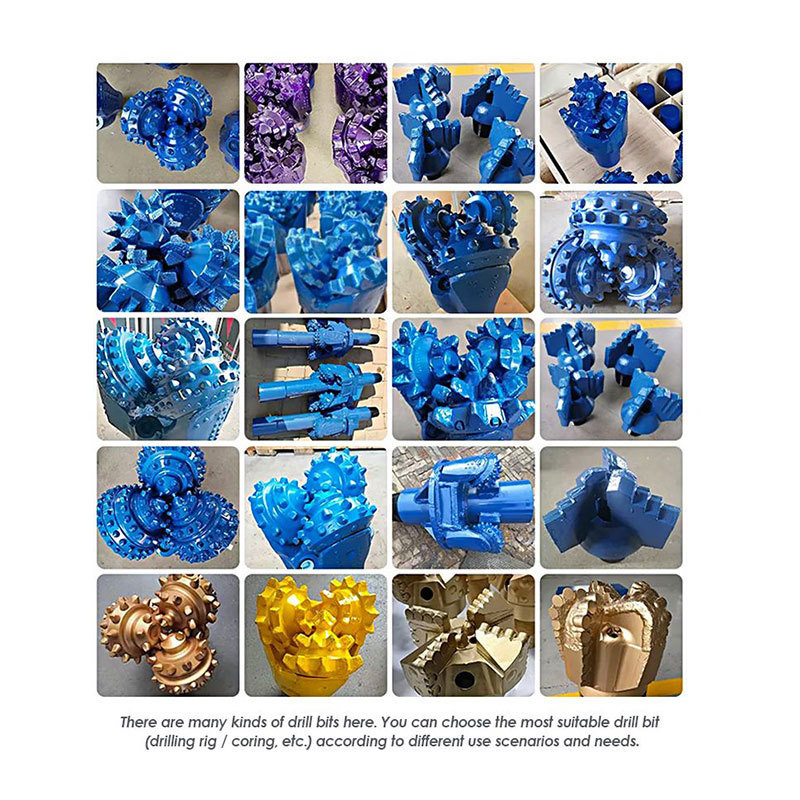

Φ100mm-Φ240mm

|

|

Lift height

|

The highest point of the machine is 2.5 meters

|

|

Lifting force

|

1000KG

|

Product Detail

Processing Procedure:

Connect the drill bit to the drill pipe tightly, the main controller raises the head with a hand-operated hoist, and the other person cooperates to connect the drill pipe with the drill bit. The hand-held drill pipe slowly puts the drill bit through the base hole and puts it into the drilling hole, straightens it vertically, starts the drilling rig and the water pump, and the drill pipe rotates and drives into the ground.

Note:

1. The drill bit rotates clockwise when drilling, and cannot be reversed, so as to avoid the disjoint sliding of the drill pipe.

2. After driving in the drill pipe, the cooperator closes the safety buckle, inserts the unloading rod card, the master controller turns on the reverse gear and rotates the drill pipe counterclockwise, the lifter head is separated from the drill pipe, lift the machine head, and the cooperator takes another drill pipe, Manually rotate the top wire to connect the machine head, the lower end joint is docked, the main control operator turns on the machine and rotates clockwise to tighten the drill pipe, open the insurance card, remove the unloading card, turn the machine clockwise, and continue to drill.

1. The drill bit rotates clockwise when drilling, and cannot be reversed, so as to avoid the disjoint sliding of the drill pipe.

2. After driving in the drill pipe, the cooperator closes the safety buckle, inserts the unloading rod card, the master controller turns on the reverse gear and rotates the drill pipe counterclockwise, the lifter head is separated from the drill pipe, lift the machine head, and the cooperator takes another drill pipe, Manually rotate the top wire to connect the machine head, the lower end joint is docked, the main control operator turns on the machine and rotates clockwise to tighten the drill pipe, open the insurance card, remove the unloading card, turn the machine clockwise, and continue to drill.

FAQ

Packaging & Shipping

Hot Searches