- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Fect

-

Voltage:

-

220/380 V

-

Dimension(L*W*H):

-

3650 x 2000(+1200) x 1800 mm

-

Weight:

-

8 kg

-

Core Components:

-

corrugated board die cutting press machine

-

Keyword:

-

cardboard flat bed die cutting machine

-

Max paper size:

-

820*620 mm

-

Min paper sizes:

-

340*280 mm

-

Max cutting size:

-

770*600 mm

-

Function:

-

die cutting ( hot stamping, stripping, embossing, heat cutting)

-

Application:

-

Corrugated Board, white paper cardboard

-

Precision:

-

0.1mm

-

Paper thickness:

-

Corrugated Board<4mm; white cardboard 0.1-2 mm

-

Cutting speed:

-

7000 times/h

-

Item name:

-

China corrugated die cutting press machine for die cutting cardboard

Quick Details

-

Type:

-

Die-cutting Machine

-

Production Capacity:

-

70000 times/min

-

Max. workable width:

-

620 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Fect

-

Voltage:

-

220/380 V

-

Dimension(L*W*H):

-

3650 x 2000(+1200) x 1800 mm

-

Weight:

-

8 kg

-

Core Components:

-

corrugated board die cutting press machine

-

Keyword:

-

cardboard flat bed die cutting machine

-

Max paper size:

-

820*620 mm

-

Min paper sizes:

-

340*280 mm

-

Max cutting size:

-

770*600 mm

-

Function:

-

die cutting ( hot stamping, stripping, embossing, heat cutting)

-

Application:

-

Corrugated Board, white paper cardboard

-

Precision:

-

0.1mm

-

Paper thickness:

-

Corrugated Board<4mm; white cardboard 0.1-2 mm

-

Cutting speed:

-

7000 times/h

-

Item name:

-

China corrugated die cutting press machine for die cutting cardboard

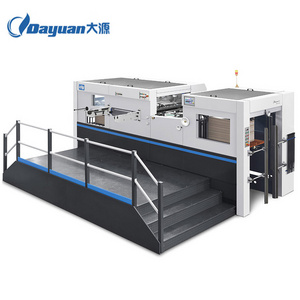

China corrugated die cutting press machine for die cutting cardboard

- Die cutting

- Hot stamping

- Hot cutting

- Embossing

China corrugated die cutting press machine for die cutting cardboard is a key equipment for printing finishing such as die cut, crease and embossing etc.

♦

Application

♦

PF-800 China corrugated die cutting press machine for die cutting cardboard is specially designed for die cutting and creasing the paperboard, corrugated board, PP or PVC plastic sheet, etc.

♦

Technical Paramters

♦

|

Model |

PF-800 |

PF-920 |

PF-1080 |

|

Max. Paper Size |

820*620mm |

920*650mm |

1080*780mm |

|

Min. Paper Size |

340*280mm |

360*290mm 200*150mm(optional) |

400*330mm |

|

Max. Die Cutting Size |

770*500mm |

900*620mm |

1075*770mm |

|

Die cutting precision |

≤±0.1mm |

≤±0.125mm |

≤±0.1mm |

|

Max. Work Speed |

7000 sheets/h |

4800 sheets/h |

7000 sheets/h |

|

Pre-stacking height |

1100mm |

1250mm |

1550mm |

|

Collection stack height |

980mm |

1000mm |

1400mm |

|

Main motor power |

7.5kw |

11kw |

11kw |

|

Total Power |

12.75kw |

18kw |

17.8kw |

|

Weight |

8000kg |

10000kg |

17000kg |

|

Overall Dimension [L x W + (platform) x H] |

3650*2000(+1200)*1800 mm |

4200*3600(+1200)*2030 mm |

6800*3780(+1200)*2050 mm |

|

Max. die cutting pressure |

200t |

150t |

300t |

|

Max Thickness of Paper |

Corrugated paper≤4mm Cardboard 0.12-2mm |

Corrugated paper≤4mm Cardboard 0.12-2mm |

Corrugated paper≤4mm Cardboard 0.1-2mm |

|

Min. gripper size |

7mm |

7mm |

7mm |

♦

Features

♦

1. Complete design, accurate installation, high stability, high security, low noise.

2. Adopt worm, worm gear, crankshaft transmission, high cutting pressure, and high durability

3. High precision intermittent mechanism, high cutting precision, runningsteadily.

4. AdoptEuropean feeder, suction adjustable, steadily, precise, good paperapplicability.

5. Non-stop feeding, pre-stacking and collection device can shorten theauxiliary time, improve the efficiency.

6. Automatic pressure adjustment system, pressure digital display.

7. Human-friendly designed die frame and baseplate, makes installation,adjustment convenient.

8. Pneumatic die locking device, die frame fixed more steadily, accurately, timesaving.

9. Front lay, side lay, feeding device fine tuning device, paper positioning moreaccurate.

10. Double sheet, crooked sheet, empty sheet optoelectronic detecting deviceensure the paper in the right position, reduce waste.

11. Electronic control module design, adopt imported electronic components,ensure the accuracy and reliability.

12. Touch screen man-machine interface, real-time monitor the runningsituation,makes machine adjustment, trouble shooting more convenient.

13.Cycling cooling oil supply system ensure the movement parts getadequatelylubricated to ensure the durability.

14. Adopt fixed quantity at fixed timing oil supply system, ensure the movementparts get adequately lubricated to let better durability.

♦

Details

♦

Unique drive gears are adopted such as high-precision indexing mechanism, pneumatic closed up, pneumatic clutch, overload protection, manual compression relief etc., to ensure stable and high speed running of the machine.

This China corrugated die cutting press machine for die cutting cardboard is equipped with practical and reliable mechanisms such as pre-stack device, secondary delivery mechanisms, manual sampling, etc. which ensure the excellent performance of the machine.

Electrical components and driving elements of internationally known brands to ensure die cutting precision and reliability of running.

Also man-machine interface is able to monitor machine running status, troubleshooting and indicating relevant help information which fully actualizes man-machine communication.

|

PF-800Q |

PF-800T |

PF-800TQ |

|

|

|

Lead edge feeding automatic flatbed die cutting machine

| Package detail |

Woodencase in 20 feet container

|

| Package size | 1050x530x255cm |

| Gross weight | 8T |