- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

0Cr23Al5

-

Shape:

-

Wire

-

Material:

-

Ferro Chrome Aluminium

-

Chemical Composition:

-

Cr20.5%-23.5%

-

Product name:

-

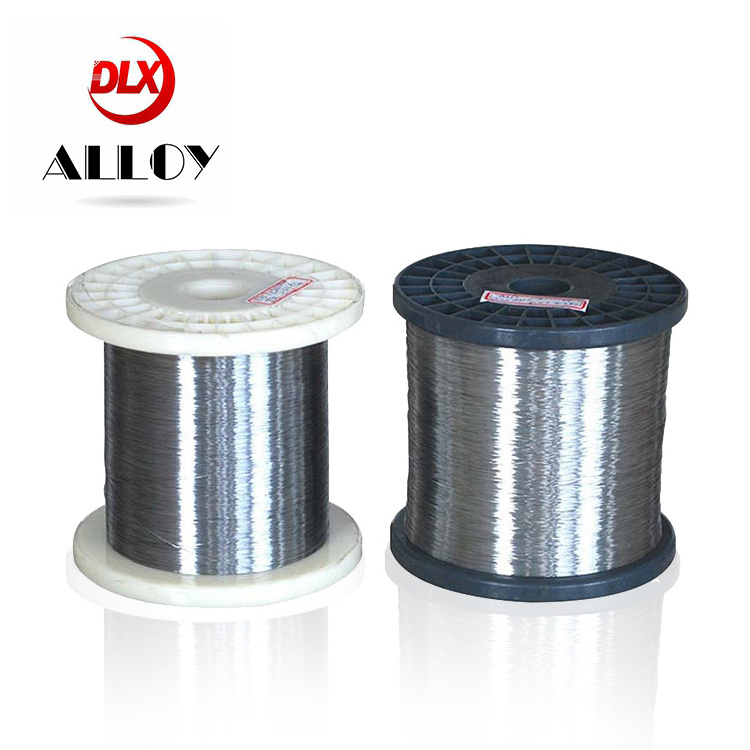

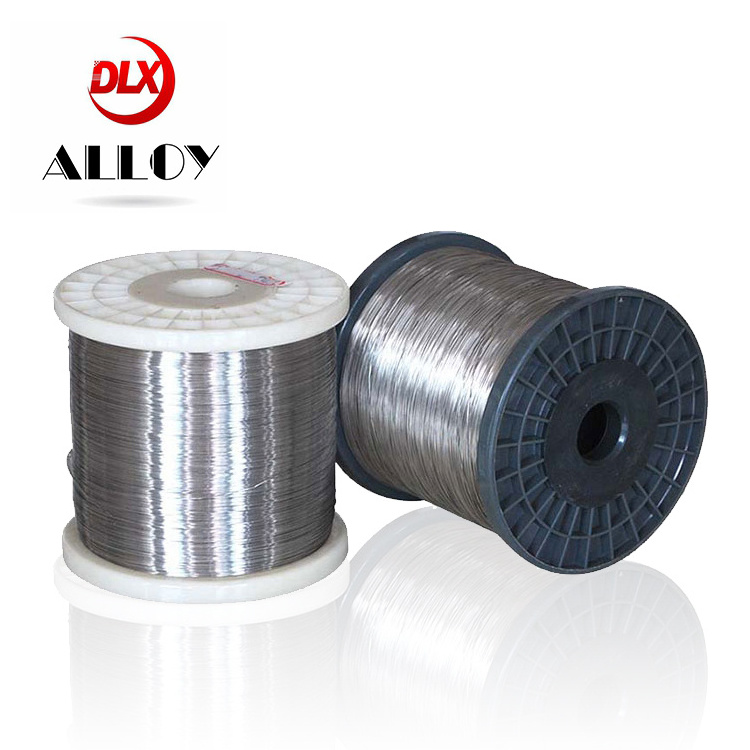

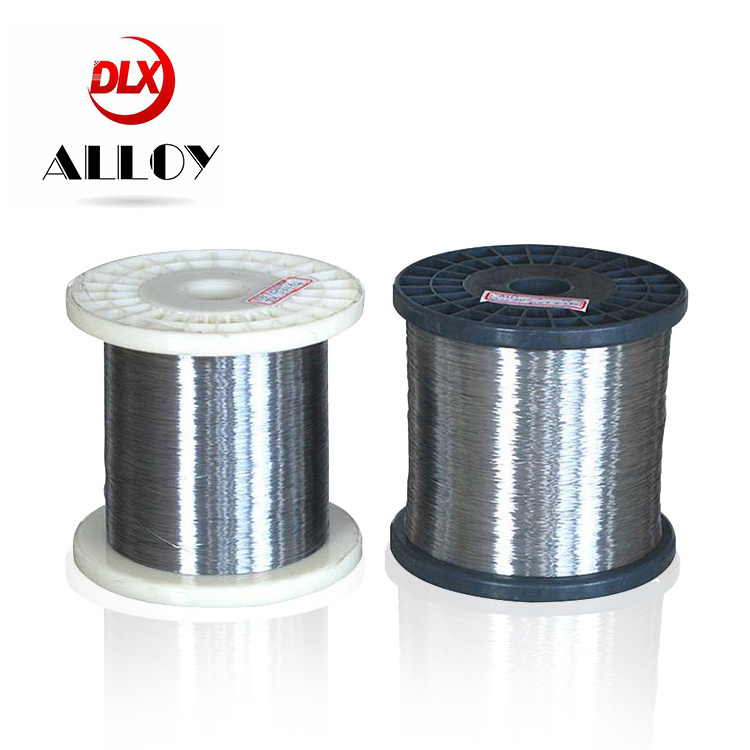

FeCrAl Alloy Wire

-

Conductor type:

-

Solid

-

Certificate:

-

ISO

-

Condition:

-

Bright, Annealed, Soft

-

Usage:

-

furnace, oven, heating elements

-

Surface treatment:

-

hydrogen annealing

-

Size:

-

0.05-7.5mm

Quick Details

-

Application:

-

furnace, oven

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

DLX

-

Model Number:

-

0Cr23Al5

-

Shape:

-

Wire

-

Material:

-

Ferro Chrome Aluminium

-

Chemical Composition:

-

Cr20.5%-23.5%

-

Product name:

-

FeCrAl Alloy Wire

-

Conductor type:

-

Solid

-

Certificate:

-

ISO

-

Condition:

-

Bright, Annealed, Soft

-

Usage:

-

furnace, oven, heating elements

-

Surface treatment:

-

hydrogen annealing

-

Size:

-

0.05-7.5mm

furnace fecral resistance heating wire

Fe-Cr-Al Alloy

Longer high temperature service life

Superior oxidation resistance

Higher resistance

High quality Low Price FeCrAl Alloy Wire

Fe-Cr-Al alloy has the characteristic of high resistivity,low temperature resistance coefficient,high operating temperature,good anti-oxidation and anti-corrosion under high temperature.

It is widely used in industrial furnace, household appliances, industry furnace, metallurgy, machinery, aircraft, automotive, military and other industries producing heating elements and resistance elements.

nichrome heating alloy includes pure nickel, NiCr alloy, Fe-Cr-Al alloy and copper nickel alloy.

FeCrAl resistance wire grade:

0

Cr25Al5,

1Cr13Al4, 0

Cr23Al5,

0

Cr27Al7Mo2, 0Cr21Al6Nb, 0

Cr21Al4,

0Cr21Al6.

In the form of wire, ribbon and strip, one kind of material Fe-Cr-Al alloy.

Wire: 0.018mm-10mm

Rod: 8mm-50mm

Ribbon: 0.05*0.2mm-2.0*6.0mm

Strip: 0.5*5.0mm-5.0*250mm

| Alloy Nomenclature Performance | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| Chemical Compostion (%) | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 20.5-23.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.3 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

| Re | opportune | opportune | opportune | opportune | opportune | opportune | opportune | |

| Fe | Rest | Rest | Rest | Rest | Rest | Rest | Rest | |

| -- | -- | -- | -- | -- | Nb0.5 | Mo1.8-2.2 | ||

| Max. continuous service temp. of element(%) | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

| Resistivity at 20℃(μΩ*m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

| Density(g/cm3) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

| Thermal conductivity(KJ/m*h*℃) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | -- | |

| Coefficient of lines expansion(α*10-6/℃) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

| Melting point approx.(℃) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

| Tensile strength(N/mm2) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

| Elongation at rupture(%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

| Variation of area(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

| Repeat Bending frequency(F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

| Hardness(H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| continuous service time(Hours/℃) | -- | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥50/1350 | ≥50/1350 | |

| Micrographic structure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

| Magnetic properties | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

Other product series :

FeCrAl Alloy: OCr15Al5,1Cr13Al4, 0Cr21Al4, 0Cr21Al6, 0Cr25Al5, 0Cr21Al6Nb,0Cr27Al7Mo2. Go to Review

NiCr Alloy: Cr20Ni80,Cr30Ni70,Cr20Ni35,Cr20Ni30,Cr15Ni60. Go to Review

CuNi Alloy: NC003 ,NC010,NC012,NC015,NC020,NC025,NC030,NC040,NC050,Constantan,6J8/11/12/13/. Go to Review

Welding wire: ERNiCrMo-3/4/13, ERNiCrFe-3 /7,ERNiCr-3/7,ERNiCu-7,ERNi-1, ER70S-6. Go to Review

Thermocouple alloy: K,J,E,T,N, S,R,B,KX,JX,EX,TX,NX. Go to Review

Inconel alloy: Inconel 600,601,617,X-750,625,690,718,825. Go to Review

Incoloy alloy: Incoloy 800,800H,800HT,825,925. Go to Review

Hastelloy alloy: HC-276,C-22,C-4,HB,B/2/3,X,N. Go to Review

Monel Alloy: Monel 400,K500. Go to Review

High-temperature alloy : A-286,Nimonic80A/90,GH131,GH1140,GH36,GH2706,GH2901,GH3625,GH3536,GH4169. Go to Review

Precision alloy series: 1J33,3J01,3J9,4J29,4J32.4J33,Invar36,4J45.FeNi50. Go to Review

Thermal spray alloy: Inconel 625,Ni95Al5,Monel400,45CT,HC-276,K500,Cr20Ni80. Go to Review