- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customers Local Voltage

-

Power:

-

Multi Power

-

Dimension(L*W*H):

-

Customized Size

-

Weight (KG):

-

5200

-

Equipment Name:

-

Physical Vapor Deposition Machine (PVD) For Hard Tool Coating

-

Application:

-

Surface Treatment / Functional PVD hard coatings

-

Coating film:

-

TIN TIC CrN ZrN TICN

-

Coating color:

-

PVD coating colors

-

Coating Feature:

-

No chemical waste

-

Coating Technology:

-

Magnetron sputtering + arc deposition

-

Control System:

-

Touch Screen Programming

-

Chamber material:

-

SUS304 Stainless Steel

-

Raw material:

-

Chrome, titanium, silver, etc

Quick Details

-

Machine Type:

-

PVD vacuum coating machine - Arc deposition

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

Hongfeng VAC

-

Voltage:

-

Customers Local Voltage

-

Power:

-

Multi Power

-

Dimension(L*W*H):

-

Customized Size

-

Weight (KG):

-

5200

-

Equipment Name:

-

Physical Vapor Deposition Machine (PVD) For Hard Tool Coating

-

Application:

-

Surface Treatment / Functional PVD hard coatings

-

Coating film:

-

TIN TIC CrN ZrN TICN

-

Coating color:

-

PVD coating colors

-

Coating Feature:

-

No chemical waste

-

Coating Technology:

-

Magnetron sputtering + arc deposition

-

Control System:

-

Touch Screen Programming

-

Chamber material:

-

SUS304 Stainless Steel

-

Raw material:

-

Chrome, titanium, silver, etc

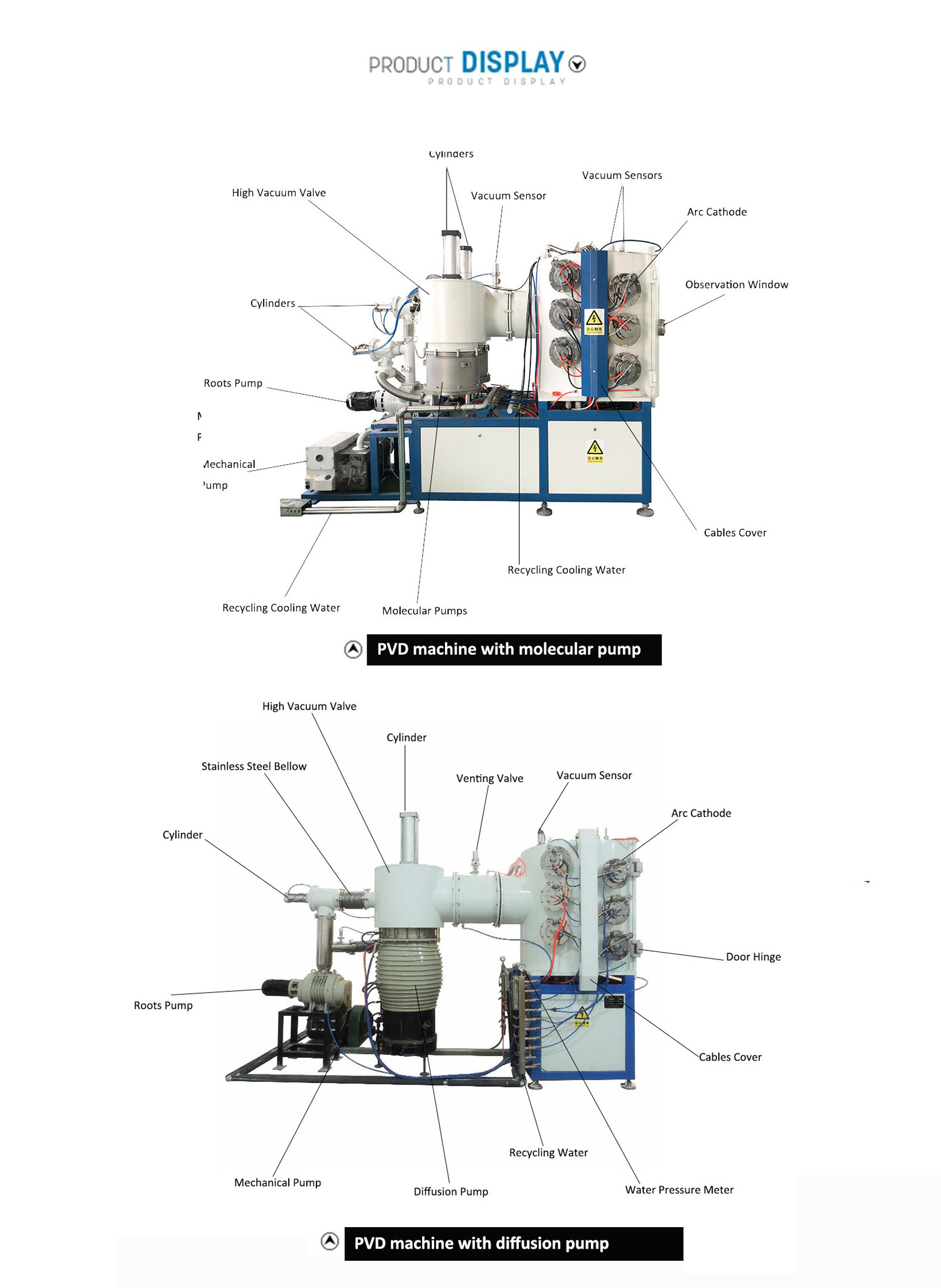

Physical Vapor Deposition Machine (PVD) For Hard Tool Coating

ARC Series

ARC series, based on the arc deposition technology, are the most suitable coating system for producing PVD hard coatings on metal tools, molds and dies, etc.

Features

:

- Chamber size: φ 600mm-φ1800mm(Can be customized)

- 3-point vacuum level measuring,2 -point temperature measuring

- High power ion source achieving uniformed, larger ion deposition distribution over a larger area at high ion current density.

- Different metal and alloy layers can be deposited by multi arc sources

- Auto-deposition control system for fully automated process.

- Center-driving or planetary substrate dome is selectable.

- Diffusion pump(or turbo molecular pumps) plus mechanical pumps for high vacuum pumping

Specifications

| Model | ARC series |

| Vacuum Chamber | SUS304, φ600mm-1200×600-1200mm (H) |

| Substrate Dome Size | Depends on the customer's needs |

| Substrate Dome Rotation Speed | 10 rpm to 50 rpm (Variable) |

| Arc Evaporation Source | From 2 to 16 sets |

| Vacuum System | Roughing Pump, Diffusion Pumps or Turbo Molecular Pump + Mechanical pumps |

Performance

| Ultimate Pressure | 5.0×10 -4 Pa or lower |

| Pump Down Rate | 25 minutes (Atm. to 5.0×10 -3 Pa) |

| Substrate Heater | 550℃ (max.) |

Utility

| Layout Dimensions | 5000mm (W)×6500mm (D)×3500mm (H) approx. |

| Power Requirements | 3-phase, 380V, 50/60Hz, 100-180kVA approx. |

| Cooling Water Flow Rate | 140/min. or greater |

| Compressed Air Pressure | 0.5MPa or higher |

| Gross Weight | 8500kg approx. |

Complete Process:

Hot Searches