- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Weight:

-

1600 KG

-

Product name:

-

Oil Refinery Machine

-

Raw material:

-

Soybean

-

Function:

-

Making Edible Oil

-

After-sales Service Provided:

-

Online Support

-

Capacity:

-

300~500kg/h

-

Feature:

-

High Efficiency Low Cost

-

Advantage:

-

Energy Saving Low Residual

-

Used for:

-

Oil Making Expeller

-

Keyword:

-

Mini Oil Expeller

-

Material:

-

Stainess Steel

Quick Details

-

Production Capacity:

-

2t-15t/day

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ocean lucky

-

Voltage:

-

380V

-

Weight:

-

1600 KG

-

Product name:

-

Oil Refinery Machine

-

Raw material:

-

Soybean

-

Function:

-

Making Edible Oil

-

After-sales Service Provided:

-

Online Support

-

Capacity:

-

300~500kg/h

-

Feature:

-

High Efficiency Low Cost

-

Advantage:

-

Energy Saving Low Residual

-

Used for:

-

Oil Making Expeller

-

Keyword:

-

Mini Oil Expeller

-

Material:

-

Stainess Steel

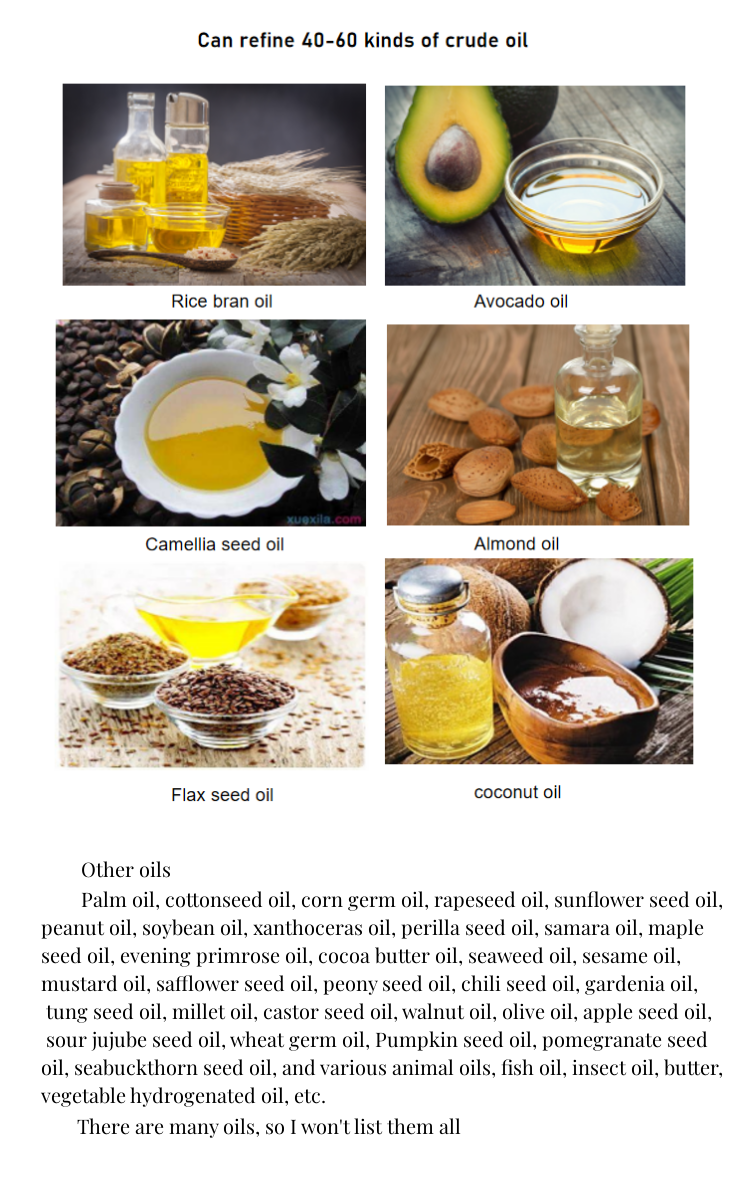

The edible oil refining machine is a small refining equipment specially used for refining edible oil and crude oil, which can also be called edible oil refining equipment. It is composed of refining tanks, bleaching tanks, filters, oil pumps, and electric motor control systems. It can remove impurities in the edible oil and crude oil through processes such as crude oil degumming, deacidification, drying, and decolorization, reaching advanced edible standards, allowing the edible oil to have a longer storage life, better color, and odor More green and healthy.

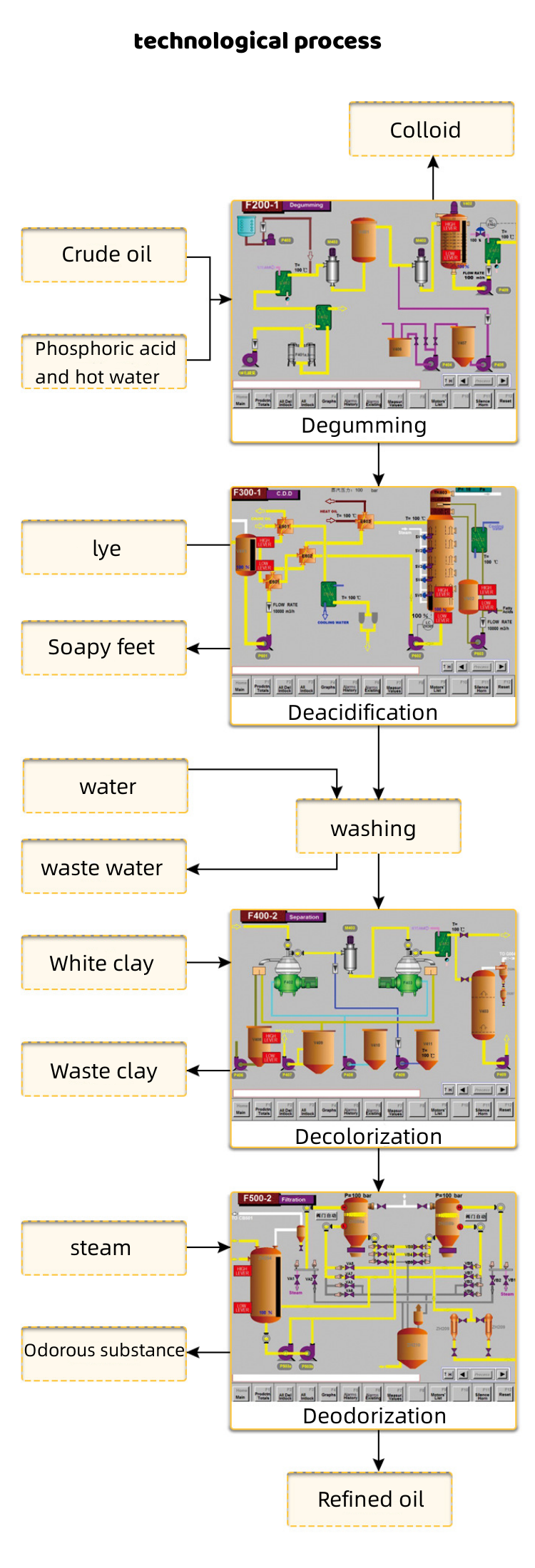

1. Hydration degumming: Hydration degumming is a degumming method that uses the hydrophilic properties of colloidal impurities such as phospholipids to add a certain amount of water or electrolyte dilute solution to the crude oil under stirring, allowing the colloidal impurities in the crude oil to absorb water and expand, agglomerate, and separate to remove. During the hydration degumming process, the substances that can be condensed and precipitated are mainly phospholipids, in addition to proteins, mucus, and trace metal ions that bind to phospholipids.

2.Alkali refining and deacidification: Various unrefined crude oils contain a certain amount of free fatty acids. The process of removing free fatty acids from oils is called deacidification. The methods of deacidification include alkali refining, distillation, solvent extraction, and esterification. The most widely used methods in industrial production are alkali refining and steam distillation (i.e. physical refining)

3. Oil decolorization: Oil adsorption decolorization refers to the use of certain substances that have a strong selective adsorption effect on pigments (such as bleached earth, activated clay, activated carbon, etc.) to adsorb pigments and other impurities in oil under certain conditions, thereby achieving the purpose of decolorization. The oil treated with adsorbent not only achieves the goal of improving the oil color and removing colloid, but also effectively removes some trace metal ions and some substances that can cause hydrogenation catalyst poisoning in the oil, thereby providing good conditions for further refining (hydrogenation and deodorization) of the oil.

4. Oil deodorization: Oil deodorization is a process that utilizes the difference between the volatilization of odorous substances in oil and triglycerides, and uses steam distillation to deodorize odorous substances under high temperature and high vacuum conditions. The principle of water vapor distillation (also known as stripping) for deodorization is that water vapor passes through grease containing odor components, contacts the vapor liquid surface, and is saturated by the volatile odor components and escapes at a ratio of their partial pressure, thereby achieving the purpose of deodorizing the odor components.

Effect after refining

After being processed by a refining machine, the oil has a transparent color, no precipitation after long-term storage, no foaming after cooking, and no oil smoke. It meets the national edible oil standards, and can be directly filled and sold. It is suitable for processing with supplied materials and small-scale oil processing plants.

Product parameters

Product parameters

| Model | ZY-112 | ZY-113 | ZY-115 |

| Heating Power | 3*2 | 6*3 | 9*3 |

| Air pump power |

1.1Kw |

1.1Kw | 1.1Kw |

| Capacity | 1t/day | 2t-5t/day | |

| Mixing tanker | 1unit | 2unit | 3unit |

| Voltage | 380V 3 phase | 380V 3 phase | 380V 3 phase |

| Weight | 500kg | 800kg | 1600kg |

| Size | 3100*850*2500mm | 4500*900*2500mm | 6000*2000*2500mm |

Operating methods of edible oil refining equipment

1.Before rapeseed oil is sent to the crude oil pump and enters the refining tank, it is necessary to check whether the pipeline valves are normal. After each tank of rapeseed oil is delivered, the oil inlet valve should be immediately closed. The crude rapeseed oil to be refined in the oil tank must first have foam on the oil surface to make the oil surface smooth, and stand for a proper time so that there is no foam in the oil. Adjust the crude oil temperature to 25-35 ℃

2.Preparation of alkali liquor Weigh out a specified amount of alkali liquor (it must be identified first), mix with appropriate amount of water, start the alkali pump, and circulate the alkali liquor to completely dissolve it. Reduce the alkali liquor temperature to 25-30 ℃, measure the alkali liquor wave temperature with a Baume meter, and adjust it to 10-12 °.

3. When the crude oil surface is smooth and the temperature stabilizes at 25-35 ℃, start the agitator to start mixing. First, slowly rotate (20 r/min) for stirring for 1 min, then quickly rotate (40 r/min). At the same time, open the valve of the alkali tank and add the alkali liquor. The time for adding lye is generally about 15min. After the lye is discharged, continue to quickly rotate and stir until the oil and soap particles are clearly separated. The stirring time is about 3-3.5h. When the oil and soap feet are clearly separated, change to slow stirring, open the heating steam valve (vapor pressure 1.4kgf/m*2), raise the temperature of the oil to 60 ℃ (the oil temperature should be maintained at 1 ℃/min, and the high temperature should not exceed 65 ℃), immediately stop stirring, and close the steam valve to allow it to cool and precipitate by itself (sedimentation time is about 8 hours). After checking that the pipeline of the oil delivery valve is normal, pump the oil into the water washing tank. When the pump reaches the interface between the oil and the precipitated soap feet, be careful not to pump the soap feet out while simultaneously pumping them out.

4.Water washing heats up the oil pumped into the washing tank, while starting the mixer to add 75 to 80 ℃ hot water to maintain the oil temperature at 80 to 85 ℃ (the temperature should not exceed 85 ℃). When the water has been added (the amount of water added is 15% - 20% of the oil amount, and the time for adding water is 38 to 40 minutes), stop heating and continue stirring for 15 minutes, that is, stop stirring and precipitate for 2 hours (once). Open the drain valve at the bottom of the water washing tank to drain about 3/4 of the washing water (before draining the washing water, first lift the remaining oil in the pipeline into the oil water separation tank to recover it). Then close the drain valve, open the valve leading to the oil water separation tank, and slowly add the remaining oil water mixture. During the second water washing, put all the viscous substances in the oil-water intermediate layer into the separation tank until the oil is seen, and then close the valve. Oil-water separation must be controlled by a dedicated person. When separating in the separation tank, the heating coil in the tank must be opened to raise the temperature (not exceeding 80 ℃). After separation, the water should be drained and the residual oil recovered.

Follow the above method to continue washing the oil machine with water until the washing water is completely clear. The sedimentation time for the second washing is 1.5 hours.

5.Before dehydration and transportation, first check whether the relevant pipeline valves are normal, and then pump the water washing bin into the vacuum dehydration tank. At the same time, open the steam valve, start the vacuum pump and agitator, adjust the cooling water of the condenser, and start the circulating oil pump to accelerate the circulation of oil in the vacuum dehydration tank. The vacuum degree of the vacuum dehydration tank is maintained above 0.0867MPa. The dehydration time is about 3h, calculated from the delivery of oil from the dehydration tank, and the dehydrated oil should be sampled and inspected by the quality inspector. If insufficient dehydration is found, dehydration must continue. The dehydration temperature is maintained at about 70 ℃. After dehydration, stop the vacuum pump, open the air valve, and slowly add air. Check whether the pipeline valve is normal, and then the transfer oil is cooled to 25-30 ℃ through the cooling pipe and flows into the sedimentation tank for pressure filtration.

6.Check whether the pipeline valve of the filter press is normal. Check that the oil temperature is below 30 ℃. After the oil is filtered, stop the oil filter pump and close the valve. Gently open the filter plate to allow the internal oil to flow into the oil pan, and then filter the filter residue on the cloth. Check the usage of the filter cloth and prepare for replacement or washing. The residual oil from the filter cloth shall be separated and recovered by a centrifuge.

After-sale Services:

1.Manules / Videos of machine installation, adjusting, setting, maintenance are available for you.

2. If any problems happend and you can not find out the solutions, Telecom or Online face to face communication available 24 hours.

3. ocean lucky engineers & technician are available send to your countries for services if you agree pay the expenditure.

4. The machine will have One year guranty for machine, two years guaranty for electrical part. During the warranty year if any of the parts broken not by man-made. We will free charge to replace the new one to you. The warranty will begin after the machine send out we received the B/L.

5. ocean lucky has an independent team for after-sale service. Any emergency please call the saleman or our after-sale's manager.