- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V Or Customized

-

Dimension(L*W*H):

-

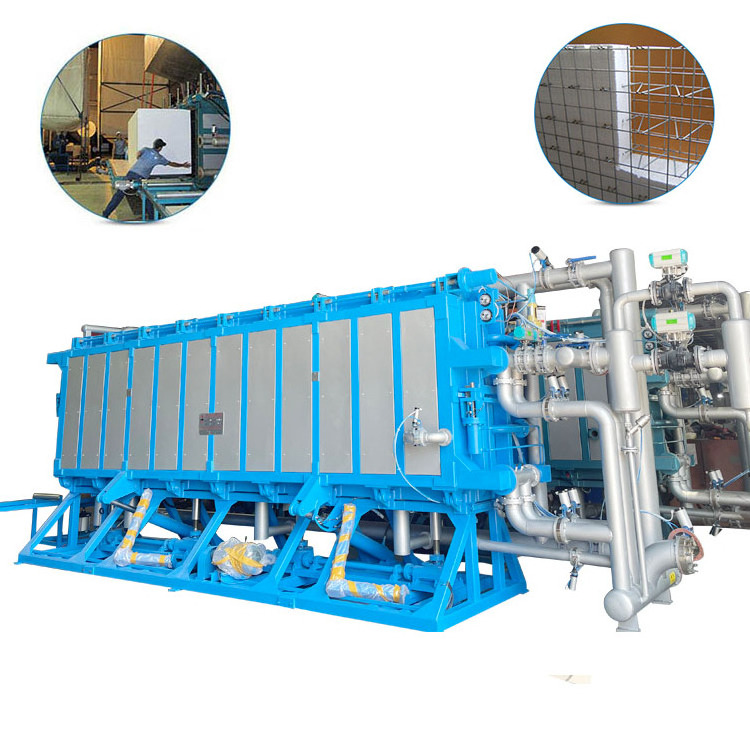

12600x4500x3100mm

-

Power (kW):

-

Depends

-

Weight (KG):

-

16000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

EPS block

-

Automatic:

-

Fully Automatic eps block moulding machine

-

Material:

-

Steel structure, stainless steel

-

EPS production line:

-

Automatic Eps Foam Production Line

-

Raw material:

-

expandable Polystyrene, Styrofoam, Thermocol

-

eps machine:

-

EPS Machine Eps Foam Boards Panel Blocks Pre-expander Machine

-

HS code:

-

84778000 foaming machine

-

Control System:

-

PLC+Touch Screen

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Milon

-

Machine Type:

-

EPS BLOCK Molding Mchine

-

Voltage:

-

380V Or Customized

-

Dimension(L*W*H):

-

12600x4500x3100mm

-

Power (kW):

-

Depends

-

Weight (KG):

-

16000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

EPS block

-

Automatic:

-

Fully Automatic eps block moulding machine

-

Material:

-

Steel structure, stainless steel

-

EPS production line:

-

Automatic Eps Foam Production Line

-

Raw material:

-

expandable Polystyrene, Styrofoam, Thermocol

-

eps machine:

-

EPS Machine Eps Foam Boards Panel Blocks Pre-expander Machine

-

HS code:

-

84778000 foaming machine

-

Control System:

-

PLC+Touch Screen

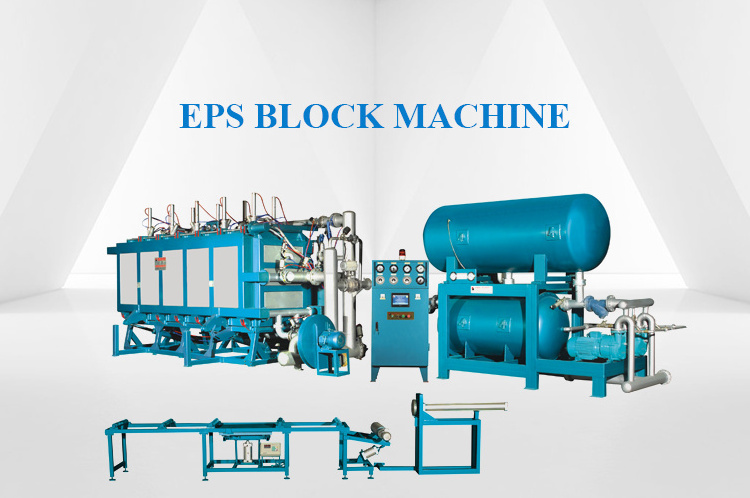

Energy saving EPS Machine Automatic Machine Eps Foam Boards Panel Blocks Pre-expander Machine Automatic Eps Foam Production Line

1. Apply PLC controller and touch screen control system.

2. Welded from high quality square profile steel and steel plate.

3. Apply unique and advanced EPS heat penetration process.

4. Advanced EPS heat penetration technique, reasonable pipeline system and unique design construction.

5. Most of the main components are of world-famous brands, with reliable performance, stable quality, long service life and low

maintenance cost.

6. Apply hydraulic pressure transmission, hydraulic ingot stripping, which makes steady running and tight locking.

7. High production efficiency. The production cycle of each plate is 2min.Automatic pneumatic charging shortening the production

time.

8. Apply high-efficient vacuum system and cooling device to improve moulding speed and reduce the moisture content. Vacuum

supported machine is high efficient for making high-density thick plate.

|

Welcome to learn us more, please to click:

Hangzhou Milon Machinery Co., Ltd.

|

|

|

|

|||