- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99.8%

-

Voltage:

-

220V/50Hz customized

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Younger

-

Dimension(L*W*H):

-

1400*800*1500mm

-

Weight:

-

350 KG

-

Name:

-

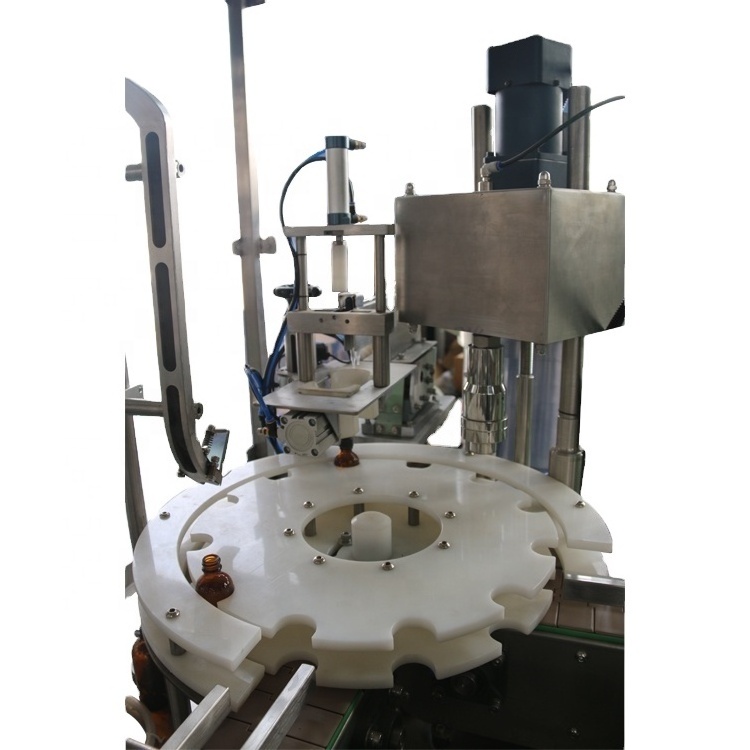

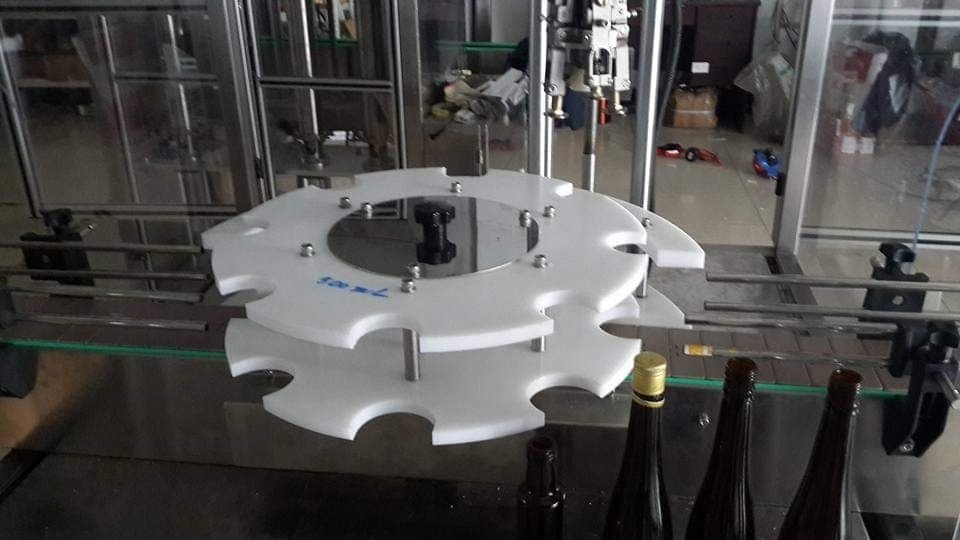

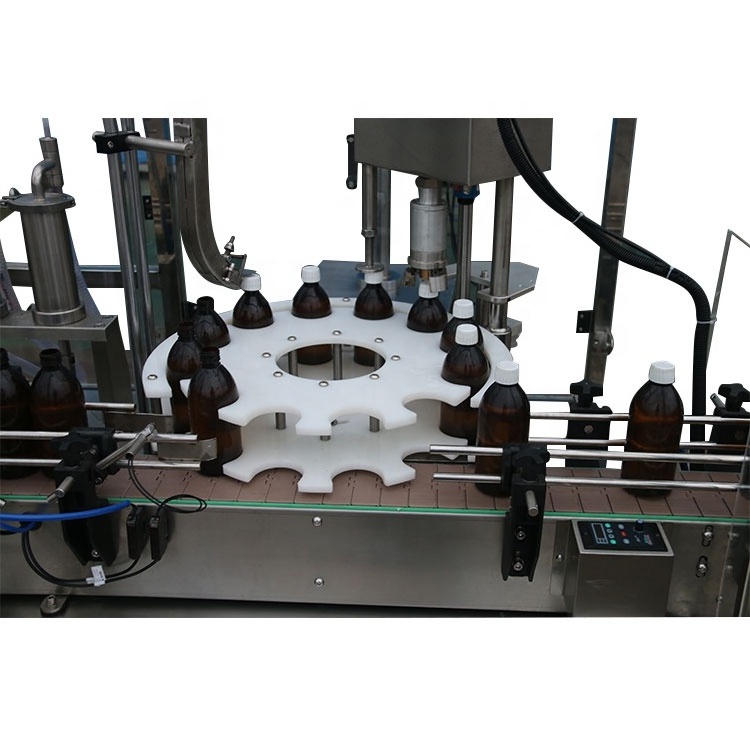

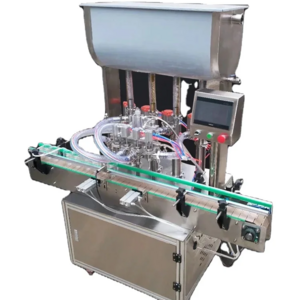

Automatic bottle clamping type cap closing machine capping machine

-

Function:

-

capping and sealing for bottle jar

-

Capacity:

-

2000-5000b/h

-

Bottle type:

-

PET Plastic/glass Bottle

-

Model:

-

YGM-F

-

Control:

-

JSCC motor, PLC+ Touch Screen

-

Speed adjustment:

-

Frequency control

-

Bottle size:

-

H:50~150mm D: 30~100mm

-

Cap diameter:

-

38-70mm

-

After Warranty Service:

-

Online video technical support

Quick Details

-

Machinery Capacity:

-

4000BPH, 2000BPH

-

Packaging Material:

-

Plastic, Glass

-

Filling Material:

-

Other

-

Filling Accuracy:

-

99.8%

-

Voltage:

-

220V/50Hz customized

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Younger

-

Dimension(L*W*H):

-

1400*800*1500mm

-

Weight:

-

350 KG

-

Name:

-

Automatic bottle clamping type cap closing machine capping machine

-

Function:

-

capping and sealing for bottle jar

-

Capacity:

-

2000-5000b/h

-

Bottle type:

-

PET Plastic/glass Bottle

-

Model:

-

YGM-F

-

Control:

-

JSCC motor, PLC+ Touch Screen

-

Speed adjustment:

-

Frequency control

-

Bottle size:

-

H:50~150mm D: 30~100mm

-

Cap diameter:

-

38-70mm

-

After Warranty Service:

-

Online video technical support

Automatic bottle clamping type cap closing machine capping machine

YG-C model screw capping machine

|

1 |

Speed |

2000-5000 b/h |

|

2 |

Cap diamter |

38-70mm |

| 3 |

Bottle size |

D:3 0-100mm , H: 5 0-150mm |

|

4 |

Error |

±0.5%( 200- 5 000ml) |

|

5 |

Voltage |

~220V , 50Hz (can be customized) |

|

6 |

Power |

1.2 Kw |

|

7 |

Speed adjustment |

frequency control |

|

8 |

Weight |

350 kg |

|

9 |

Dimension :1400mm( L )×800mm( W )×1500mm( H ) |

|

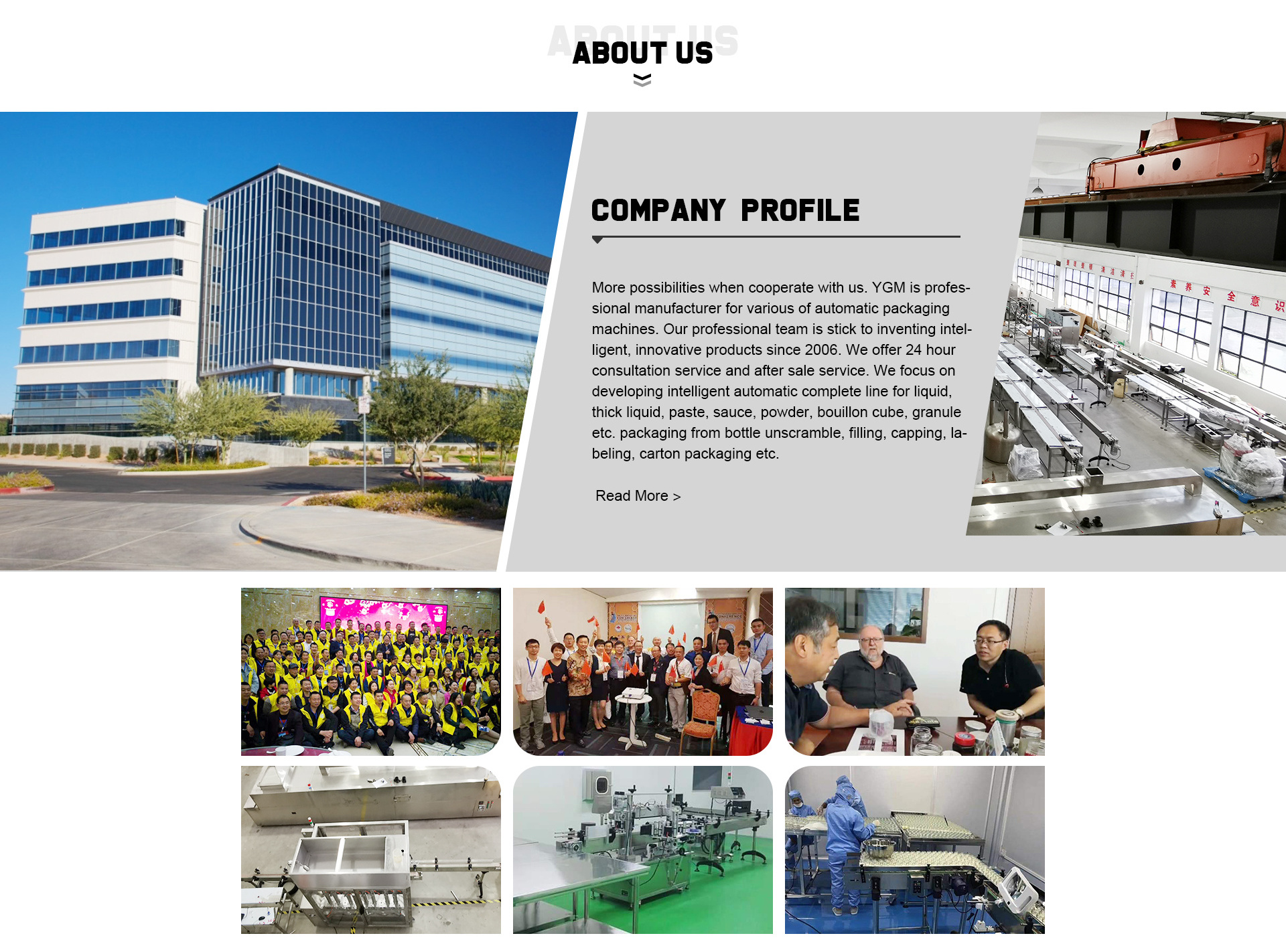

Description:

YG-C model capping machine is widely used in food, medicine, daily chemical, pesticide and other fields. It screws cap for plastic bottles, glass bottles, ceramic bottles, etc. It’s ideal for capping the lids. Which automatic completes bottle feeding, cap placing on bottles, unscrambler caps etc. The machine can be used independently, also can be combined with automatic bottle unscrambler, filling machine, aluminum foil sealing machine, labeling machine, inkjet printer and other ancillary equipment for an automatic packaging production line.

Advantages:

1. Adopt the screw-type capping, simple structure avoid slipping and pulling of the caps

2. Each major mechanism adopts JSCC variable frequency speed regulating motor. The mechanism parameters can be modified directly on the touch screen

3. The spacing and height of the action mechanism can be adjusted quickly, suitable for different kinds of bottles and caps

4. The main components made of stainless steel and aluminum-magnesium alloy, easy to clean and meet the sanitary standard.

5. The capping wheel is made of silicone rubber

6. The host power box is equipped with a touch screen to make the operation of the device more convenient and reliable.