- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

2000 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BEST MACHINE

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1.36X0.6X1.55 m

-

Hollow part volume:

-

2L

-

Clamping Force (kN):

-

100

-

Power (kW):

-

16

-

Weight (KG):

-

950 KG

-

Warranty:

-

1 Y

-

product name:

-

Semi-auto blow moulding machine for PET bottle

-

Maximum voume of products:

-

2L

-

theoretical output:

-

(0.5L) 1200-1400pcs/hour

-

blow pressure:

-

<3.5mpa

-

shift mold stroke:

-

140-170mm

-

die thickness range:

-

120-220mm

-

maximum stretch length:

-

360 mm

-

temperature control section:

-

8 section 4 group

-

cooling fan:

-

2 pcs

-

mould:

-

1 out 2

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Neck Diameter(mm):

-

100 mm

-

Max.Bottle Diameter(mm):

-

180 mm

-

Max.Bottle Height(mm):

-

300 mm

-

Bottle Volume(ml):

-

2000 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BEST MACHINE

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1.36X0.6X1.55 m

-

Hollow part volume:

-

2L

-

Clamping Force (kN):

-

100

-

Power (kW):

-

16

-

Weight (KG):

-

950 KG

-

Warranty:

-

1 Y

-

product name:

-

Semi-auto blow moulding machine for PET bottle

-

Maximum voume of products:

-

2L

-

theoretical output:

-

(0.5L) 1200-1400pcs/hour

-

blow pressure:

-

<3.5mpa

-

shift mold stroke:

-

140-170mm

-

die thickness range:

-

120-220mm

-

maximum stretch length:

-

360 mm

-

temperature control section:

-

8 section 4 group

-

cooling fan:

-

2 pcs

-

mould:

-

1 out 2

-

Marketing Type:

-

Ordinary Product

Main characteristics for Semi-auto blow moulding machine for PET bottle

1. The hyperbolic arm is arranged. The four pull rod is arranged. The clamping speed is quick. The clamping force is strong, and the closing mode is tight and fine.

2. Using the chain transfer mode system is simple and fast.

3. The only use of the overall casting frame, weight, not easy to shake.

4. Using the rigid guide rail to move the template and the former template fixed structure, the production of 100% not out of the bottle, greatly enhanced the safety and reliability of the whole machine and running smoothly.

5. Double start work and safety device, to prevent injury.

6. Advanced electrical control system design to ensure accurate and reliable execution of components.

7. Air circuit design is advanced, with a buffer device, the moving parts of the work is smooth, no impact, low noise.

8. Sealing, stretching the design of the cylinder body, left and right cylinder each into a group, not interfere with each other.

9. Isolated gas control system, to prevent the waste gas emissions pollution workshop.

10. Delivery of special bottle blank and one-way bottle fetching function, which is convenient, quick, put, improve productivity.

11. The bottle blowing machine adopts photoelectric protection device, which makes the operation more safe and reliable.

|

Model |

Unit |

BST- 2 L- 2 |

|

Bottle T ype S pecification |

||

|

Cavity |

cavity |

2 |

|

Max.volume |

L |

2 |

|

Bottle mouth maximum overall diameter |

mm |

1 0 0 |

|

Bottle biggest diameter |

mm |

18 0 |

|

Bottle maximum height |

mm |

3 0 0 |

|

Blow Molding Part |

||

|

Clamping Force |

KN |

1 0 0 |

|

Opening Stroke |

mm |

27 0 |

|

Maximum Mould Size |

mm |

390*3 45 |

|

Mould Thickness |

/ |

Adjustable |

|

Space Between Mould |

/ |

Adjustable |

|

Max. Stretch Stroke |

mm |

4 00 |

|

Working Pressure |

MPa |

0.8-1.0 |

|

Running Air Consumption |

Ltr/min |

20 0 |

|

Blowing Air Pressure |

MPa |

1.2-2.8 |

|

Blowing Air Consumption |

Ltr/min |

300 |

|

Output |

Pcs/hr |

8 00 |

|

Machine Size |

m |

1. 4 6 x 0. 58 x 1. 8 |

|

Machine Weight |

kg |

65 0 |

|

Oven |

||

|

Oven Weight |

kg |

300 |

|

Temperature Class |

class |

8 |

|

Heating Time |

s |

90-200 |

|

Voltage |

V |

220 |

|

Frequency |

Hz |

50/60 |

|

Total Power |

KW |

16 |

|

Oven Size |

m |

1. 3 5 x 0. 5 5 x 1. 1 5 |

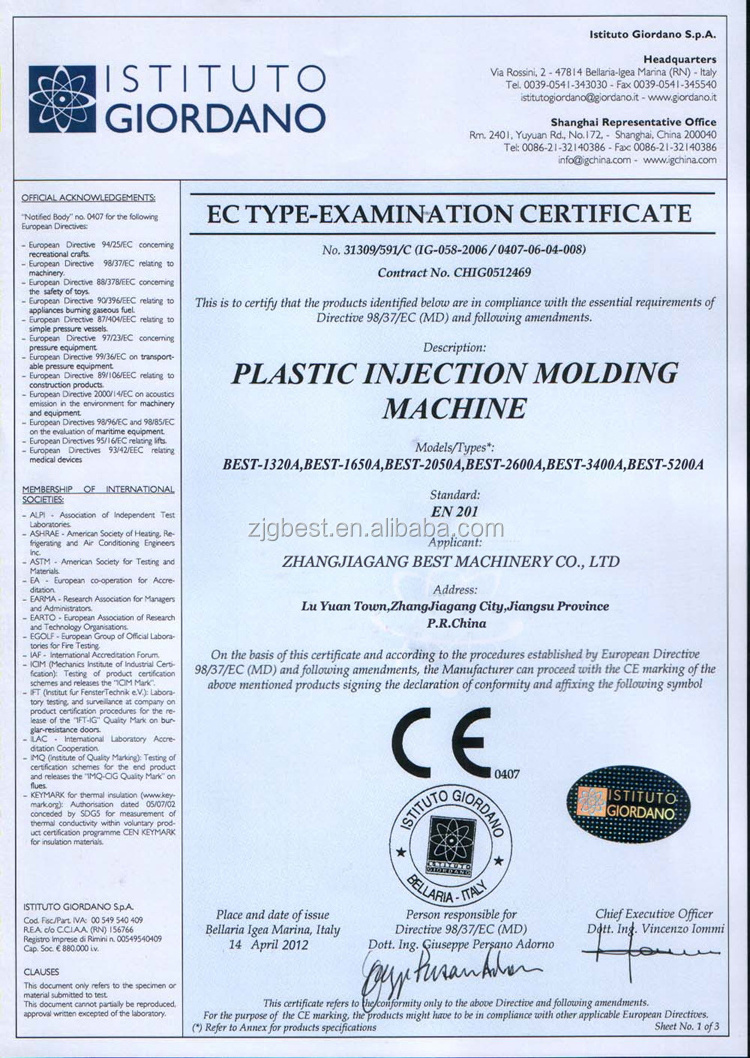

We have a professional and experience QC team, make sure good quality of every component of machine.

All of machines are assembly by our 10 years experienced workers.

Each injection molding machine with automatically working test at least 72 hours before shipment.

Each machine with one year free spare part.

We take care of our machine packing and loading.

Injection machine with anti-rust process, make sure no rust due to ocean shipment.

Each package would be fixed stable inside container, make sure no damage or crash during whole shipment.

We should take photos of loading, and send to you for reference.