- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V

-

Power:

-

1.5kw, 1.5kw

-

Weight:

-

60 KG

-

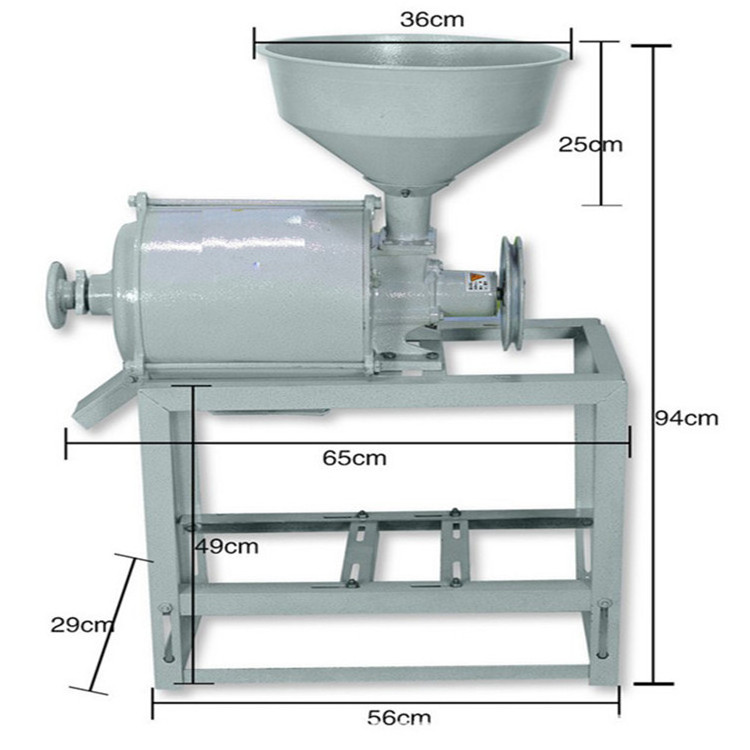

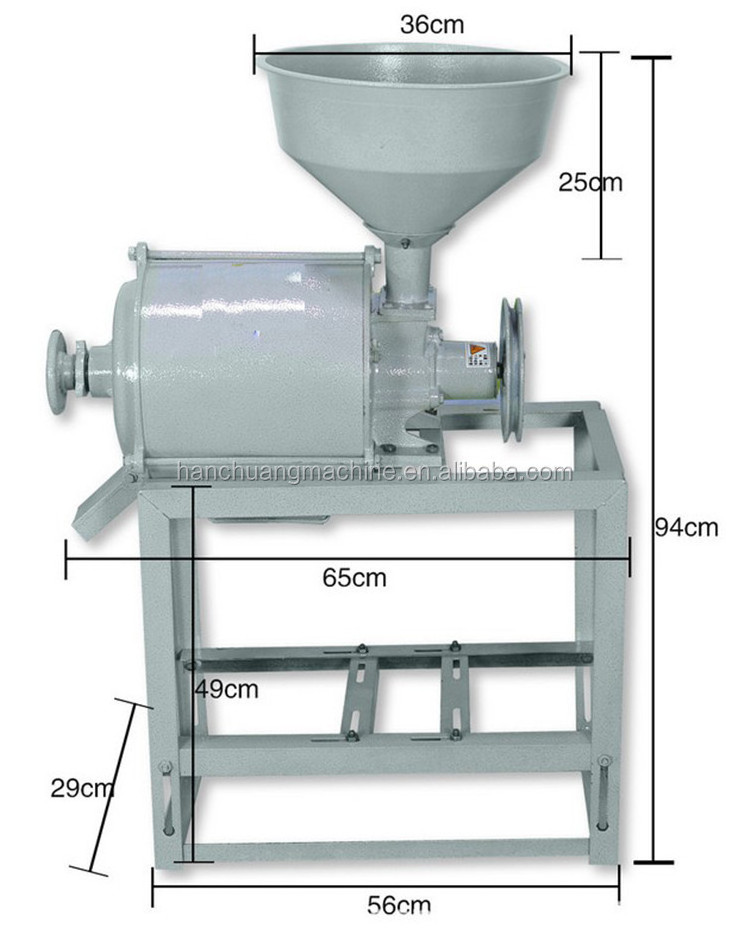

Dimension(L*W*H):

-

56*29*94cm

-

After-sales Service Provided:

-

Overseas third-party support available

-

Name:

-

Wheat flour mill machine

-

Raw material:

-

Wheat/maize

-

Usage:

-

wheat flour mill

-

Capacity:

-

30kg/h

-

Quality:

-

very best

-

Application:

-

home or small store

-

Feature:

-

Easy Operation

-

weight:

-

60kg

Quick Details

-

Place of Origin:

-

henan

-

Brand Name:

-

hanchuang

-

Production Capacity:

-

30kg/h

-

Voltage:

-

220V

-

Power:

-

1.5kw, 1.5kw

-

Weight:

-

60 KG

-

Dimension(L*W*H):

-

56*29*94cm

-

After-sales Service Provided:

-

Overseas third-party support available

-

Name:

-

Wheat flour mill machine

-

Raw material:

-

Wheat/maize

-

Usage:

-

wheat flour mill

-

Capacity:

-

30kg/h

-

Quality:

-

very best

-

Application:

-

home or small store

-

Feature:

-

Easy Operation

-

weight:

-

60kg

Maize flour milling machine/maize roller mill/wheat

flour mill price 0086-18737189043

Introduce of wheat flour mill machine

Machine structure: consists of a feed, a conical mill and a separation system. Working principle: the mating surface of the lower end of the inner and outer grinding head of the grinding machine is conical. Two centripetal ball bearings are used as the two main support points above the grinding head, and the cylinder at the lower end of the inner and outer grinding heads is used as the rotating auxiliary support. Point and adjust the clearance between the inner and outer grinding heads by the axial movement of the inner grinding head. The ground grain falls directly from the grinding head gap to the bottom of the rug, and the flour and the bran (seed skin) are separated by a brush with adjustable clearance and a bottom.

Parameters of maize flour mill machine

|

Model |

HC-180 |

|

Power |

1.5KW |

|

Motor speed |

2800r/min |

|

Capacity |

100 mesh 30 kg/h (wheat) |

|

Rotor speed |

1300r/min |

|

Rotor diameter |

180mm |

|

Weight |

55kg |

|

Package size |

56*29*94cm |

Machine pictures:

Packaging & Shipping

1. Testing Machine before package

2. Package : Inside plastic bag, outside wooden case.

3. Shipping: By sea, By air.

By sea: if customer not urgently the machine, we advice by sea, even though by sea took time is long, but by sea reduce much money about the freight, and it is good for customer if the machine is heavy and big size.

By air: it is faster than by sea, but its freight is higher much than by sea, so this kind of type always suggest for light, small size and urgently demand machine.

Pre-sale service

1.Related machines’s technical parameter will be supplied to customer.

2.According to customer’s factory size, factory layout can be provided in advance.

3. According to customer’s material cost, general formulation can be prepared well.

4.Special machine can be supplied as customer’s request.

5.Professional Advice about Market, machines, processing , materials, packing can be supplied

6. Suggesting professional ship agent or helping book ship as customer request.

After sale service :

1.Allocation chart as the buyer’s request will be supplied.

2.Operation manual will be supplied after shipment.

3.One year warrantee, life time maintenance with cost price.

4.Free easy broken spare parts will be sent with container .

5.First installation can be done by engineer.

6.Training workers in customer’s factory.