1.

More environmentally friendly

--Compared with traditional manual spraying save 25%~50% paint use

2.

Higher work efficiency

-- more products can be sprayed in the same time

3.

High-quality spray effect

--Coating&painting effect are more better than hand spray painting

4.

Full automatic machine

-- 10s to set up the coating of a plane. Say goodbye to complex control!

5.

Human Health friendly

-- Spraying booth without additional dust and paint emissions protect the health of our employees

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HAOSHENG

-

Voltage:

-

220V/380V

-

Power:

-

customize

-

Dimension(L*W*H):

-

customize

-

Weight (KG):

-

550

-

Coating method:

-

Liquid Coating, Spray Painting

-

Coating Substrate:

-

Glass, Metal, Plastic, Rubber, Ceramics, Wood, Acrylic etc.

-

Installation Method:

-

On spray paint line or in water curtain spray paint booth.

-

Product name:

-

plastic components spray painting liquid coating production line

-

Kinds of coating:

-

Liquid Coating

-

Control System:

-

PLC+Touch Screen Automatic

-

Install location:

-

Spraying Room

-

Spraying method:

-

Robot Automatic Spray

-

Coating color:

-

Multi Color

-

Advantage:

-

High Production Efficiency

Quick Details

-

Machine Type:

-

Liquid spray painting, Spray Booths, Painting Equipment, Plc Controller Programmable Logic Controller, Pre-treatment Equipment, Coating Equipment

-

Marketing Type:

-

Hot Product 2023

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HAOSHENG

-

Voltage:

-

220V/380V

-

Power:

-

customize

-

Dimension(L*W*H):

-

customize

-

Weight (KG):

-

550

-

Coating method:

-

Liquid Coating, Spray Painting

-

Coating Substrate:

-

Glass, Metal, Plastic, Rubber, Ceramics, Wood, Acrylic etc.

-

Installation Method:

-

On spray paint line or in water curtain spray paint booth.

-

Product name:

-

plastic components spray painting liquid coating production line

-

Kinds of coating:

-

Liquid Coating

-

Control System:

-

PLC+Touch Screen Automatic

-

Install location:

-

Spraying Room

-

Spraying method:

-

Robot Automatic Spray

-

Coating color:

-

Multi Color

-

Advantage:

-

High Production Efficiency

Product Description

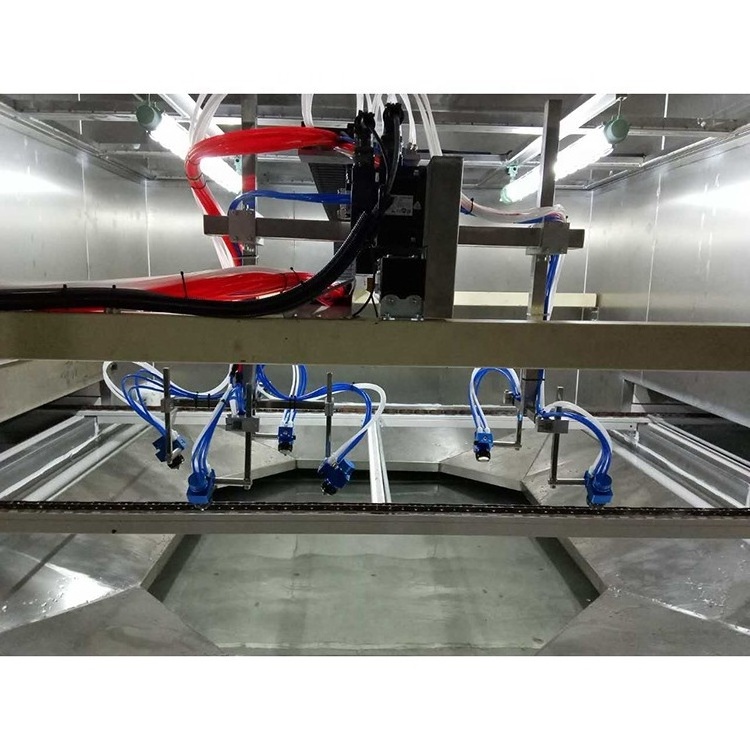

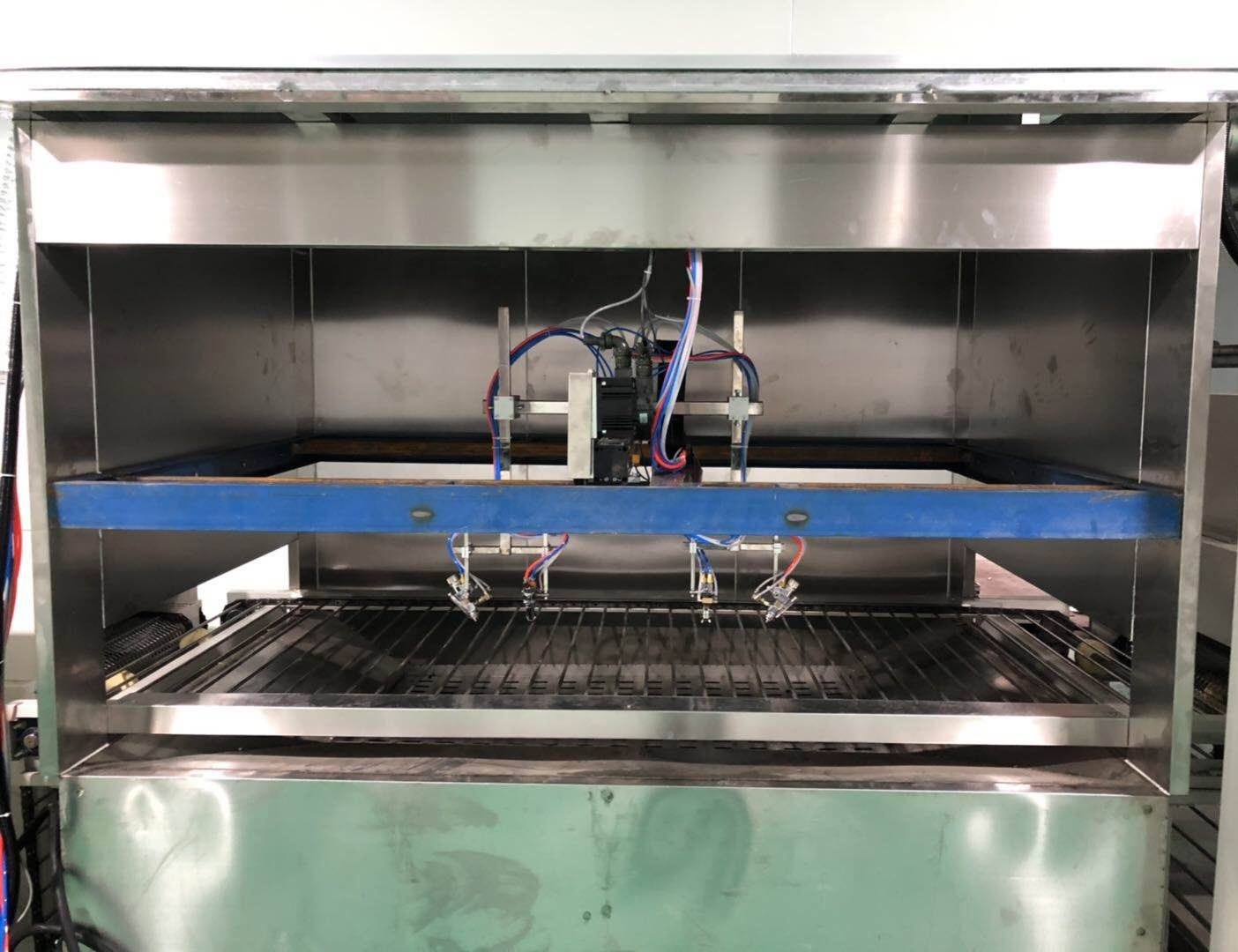

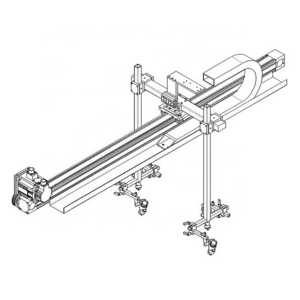

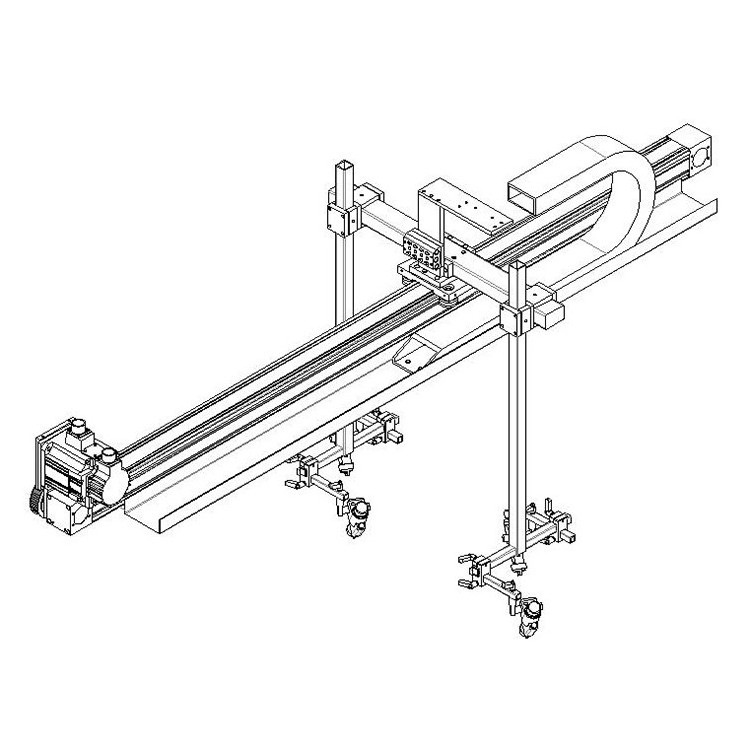

Technical Characteristics of HAOSHENG Spraying Reciprocator

6.

Accurate spray painting

, long normal running time, low paint consumption, 24 hours of uninterrupted work, and high reliability.

7. The spraying speed is fast and the spraying is uniform . The spray gun level and the front and rear angle positions can be adjusted according to the changes of the workpiece. The spraying size control is flexible.

7. The spraying speed is fast and the spraying is uniform . The spray gun level and the front and rear angle positions can be adjusted according to the changes of the workpiece. The spraying size control is flexible.

8.

Explosion-proof

, environmental

protection, high safety performance, simple operation and easy to learn.

9. Long life and easy maintenance .

protection, high safety performance, simple operation and easy to learn.

9. Long life and easy maintenance .

Applications

Plane workpiece, eg. power panel, switch panel, buttons, tempered glass touch panel, silicone buttons, keycap, acrylic panel etc.

Our Advantages

Comparison Between

Machine Painting and Manual Painting

Widely Range of Applications

Painting Scene

Our Service

Provide customized spraying solutions

Customers can provide specific information for products that need to be sprayed. We will

design spraying solutions for customers according to customers demands.

Installation and training

Customers can arrange employees to come to our company for training and learning. Once the complete coating line start building, we will assign related technician come to onsite to proceed with installation and training until trial production completed. Also, we are pleasure to share information of maintain and technology if necessary.

After-sales service

The main parts of coating system warranty is 1 year.Other parts damaged by people or consumable spare parts are out of warranty. We are offering full life maintain service and 24 hours online service. The overseas project install charge or occurring related

fee should be bear by customer.

design spraying solutions for customers according to customers demands.

Installation and training

Customers can arrange employees to come to our company for training and learning. Once the complete coating line start building, we will assign related technician come to onsite to proceed with installation and training until trial production completed. Also, we are pleasure to share information of maintain and technology if necessary.

After-sales service

The main parts of coating system warranty is 1 year.Other parts damaged by people or consumable spare parts are out of warranty. We are offering full life maintain service and 24 hours online service. The overseas project install charge or occurring related

fee should be bear by customer.

Hot Searches