- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

neweek

-

Voltage:

-

380v/50hz

-

Dimension(L*W*H):

-

1000*450*850MM

-

Motor Power (Kw):

-

15

-

Weight (KG):

-

400 KG

-

Keywords:

-

Wood Burning Pellet Making Wood Pellet Machine Line

-

Capacity:

-

200-300kg/h

-

Dia.Grinding disc:

-

250mm

-

pellet size:

-

4-12mm Diameter

-

Spare parts:

-

flat die+ rollers

-

Material Moisture:

-

15%-20%

-

Raw material:

-

Sawdust\straw\rice Husk\wood Waste

-

Material of Die and Roller:

-

20CrMnTi

-

Application:

-

Make Biomass Pellets

Quick Details

-

Pellet Diameter (mm):

-

3 - 10

-

Output (kg/h):

-

100 - 1000 kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

neweek

-

Voltage:

-

380v/50hz

-

Dimension(L*W*H):

-

1000*450*850MM

-

Motor Power (Kw):

-

15

-

Weight (KG):

-

400 KG

-

Keywords:

-

Wood Burning Pellet Making Wood Pellet Machine Line

-

Capacity:

-

200-300kg/h

-

Dia.Grinding disc:

-

250mm

-

pellet size:

-

4-12mm Diameter

-

Spare parts:

-

flat die+ rollers

-

Material Moisture:

-

15%-20%

-

Raw material:

-

Sawdust\straw\rice Husk\wood Waste

-

Material of Die and Roller:

-

20CrMnTi

-

Application:

-

Make Biomass Pellets

Products Description

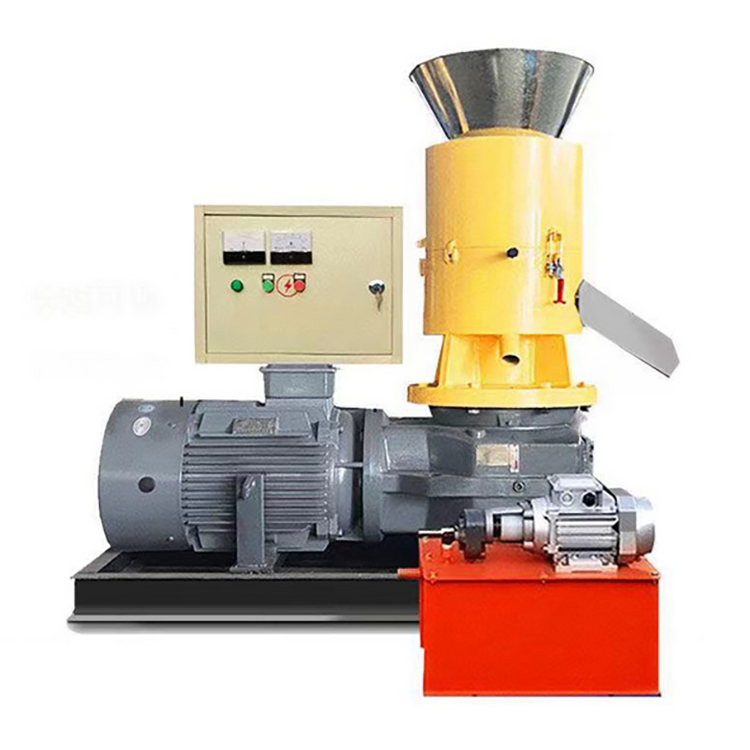

NEWEEK Granulating Cheap Charcoal Pellet Machine Wood Burning Pellet Making Wood Pellet Machine Line

Bioenergy granulator, also known as biomass solid fuel briquetting machine, is a kind of equipment that, under the action of a certain temperature and pressure, compresses all kinds of agricultural and forestry biomass with dispersed cells and no certain shape into rod, block or granular briquetting fuel after collection, drying, crushing and other pretreatment. The mainstream structure is divided into flat mode and ring mode. Its effect is to improve the transportation and storage capacity of biomass materials, improve the combustion performance and utilization efficiency, and reduce the generation of harmful substances in late combustion.

Product Paramenters

|

Model

|

Power

|

Capacity

|

Dia.Grinding disc

|

Weight

|

|

NWK-200

|

11kw

|

150-200kg/h

|

200mm

|

300kg

|

|

NWK-250

|

15kw

|

200-300kg/h

|

250mm

|

400kg

|

|

NWK-300

|

22kw

|

150-350kg/h

|

300mm

|

700kg

|

|

NWK-350

|

30kw

|

350-450kg/h

|

350mm

|

800kg

|

|

NWK-400

|

37kw

|

400-550kg/h

|

400mm

|

1000kg

|

|

NWK-450

|

45kw

|

600-700kg/h

|

450mm

|

1500kg

|

|

NWK-550

|

55kw

|

800-1000kg/h

|

550mm

|

1600kg

|

|

NWK-600

|

75kw

|

1000-1200kg/h

|

600mm

|

2500kg

|

Details Images

Main performance and characteristics:

1. Feed materials vertically and directly.

2. The mold is stationary, the pressing wheel rotates, the material is centrifugal, and the surrounding area is uniform.

3. The mold is double-layer and can be used up and down to reduce cost and save energy.

4. Annular mold, vertical structure and granulation room are used for heat dissipation and cooling.

5. Independent discharging device ensures the forming rate of particles, reasonable design and low consumption.

6. The main load-bearing elements are made of high alloy wear-resistant materials, and the service life of wearing parts is

twice that of similar products.

7. Working 24 hours, fully automatic lubrication.

1. Feed materials vertically and directly.

2. The mold is stationary, the pressing wheel rotates, the material is centrifugal, and the surrounding area is uniform.

3. The mold is double-layer and can be used up and down to reduce cost and save energy.

4. Annular mold, vertical structure and granulation room are used for heat dissipation and cooling.

5. Independent discharging device ensures the forming rate of particles, reasonable design and low consumption.

6. The main load-bearing elements are made of high alloy wear-resistant materials, and the service life of wearing parts is

twice that of similar products.

7. Working 24 hours, fully automatic lubrication.

Wood pellet mill can press biomass pellet and fertilizer granules from biomass waste or fertilizer waste, raw materials such as biomass from sawdust, rice husk, agricultural stalk, straw, peanut shell, sun flower, lucerne ,paper ect fertilizer waste such as animal manure, plant waste, chemical products and so on.

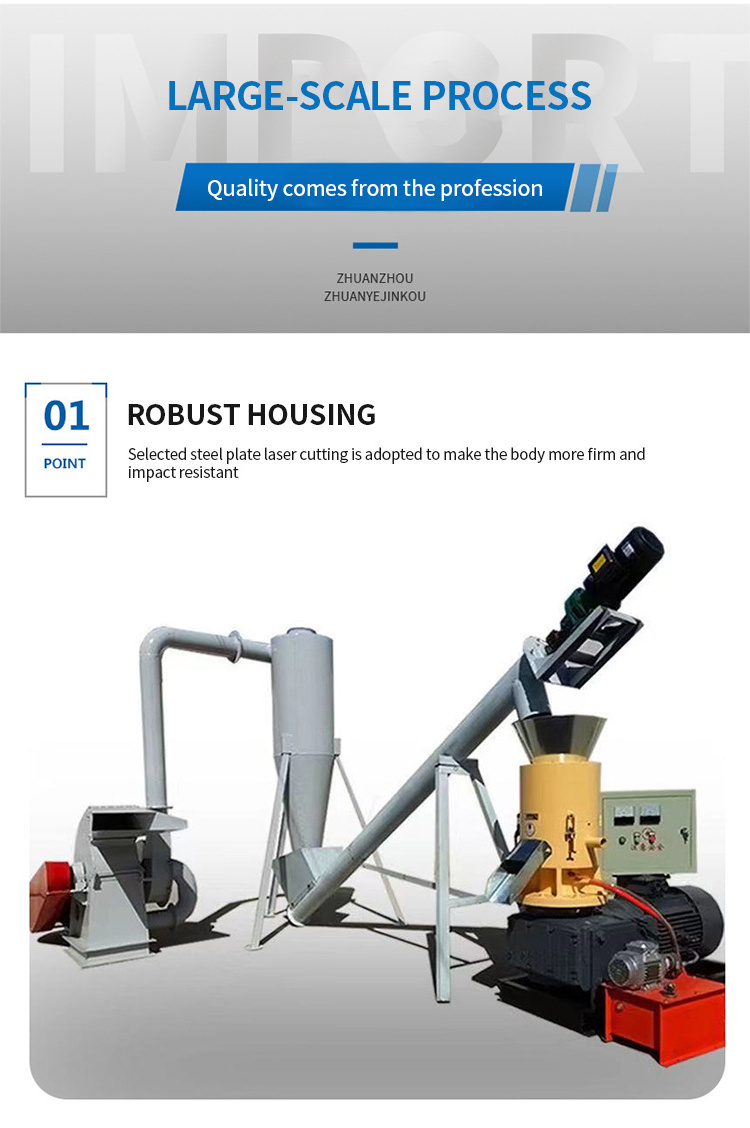

Robust housing:Selected steel plate laser cutting is adopted to make the body more firm and impact resistant

Variable speed reducer:The innovative design of motor and reducer is integrated to reduce transmission consumption, improve efficiency and reduce energy consumption.

Stable performance:Manufactured by a large factory, low energy consumption, stable performance and convenient maintenance

Simple operation:The product has a single structure, simple operation and convenient use.

Hot Searches