- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

130x60x180

-

Weight (KG):

-

800

-

Power (kW):

-

1

-

Certification:

-

ISO

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

HAVEN

-

Voltage:

-

380V or customized

-

Dimension(L*W*H):

-

130x60x180

-

Weight (KG):

-

800

-

Power (kW):

-

1

-

Certification:

-

ISO

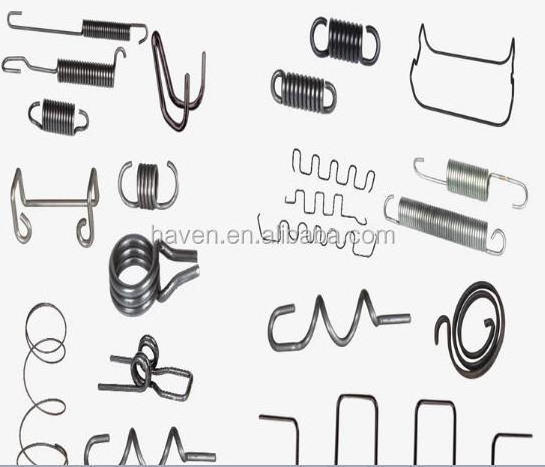

4 Axis Cnc stainless steel sofa car cushion wire spring coiling forming making machine

Mechanical features and functions:

1. C omputer control systems imported from Taiwan and imported servo motors;

2. T he computer is English interface, easy to operate, accurate positioning, the computer can control 4 servo motors, all motors can be operated synchronously or separately;

3. W ith precision detection and tracking equipment, if there are unqualified products can automatically stop;

4. According to the working condition on the fluorescent screen, the outer diameter angle of the product can be corrected at any time;

5. Mechanical automatic parts are automatically lubricated for oil supply design to ensure long-term operation of the equipment;

6. W hen the wireless, disconnected, entangled line automatic shutdown design and automatic acceleration of the wire frame, making production easier and more effective;

7. Suitable for the production of double torsion springs, straight springs, pagoda springs, tension springs, rectangular springs, wire forming, steel vortex springs, springs and various fancy springs, complex and difficult shaped springs (computer spring machines).

Main specification:

|

Model |

CNC-8422 |

CNC-8435 |

CNC-8445 |

CNC-8450 |

|

Max steel wire . (mm) |

Dia0. 3 -Dia2.5 |

Dia1.0-Dia3.5 |

Dia1.5-Dia4.5 |

Dia2.0-Dia5.0 |

|

Total power(kw) |

6.9 |

11.2 |

13.2 |

17 |

|

Number of Axis |

4 |

4 |

4 |

4 |

|

N umber of feeding roller |

3 pairs |

3 pairs |

3 pairs |

3 pairs |

|

Servo motor(kw) W ire feeding Core Spinner Camshaft |

2.7 0.75 0.75 2.7 |

4.5 1.0 1.2 4.5 |

5.5 1.0 1.2 5.5 |

7.0 5.5 5.5 7.0 |

|

Machine size(cm) |

130x60x180 |

170x98x210 |

170x100x210 |

190x120x220 |

|

Machine weight(kg) |

800 |

1900 |

1950 |

2550 |

Our Machine

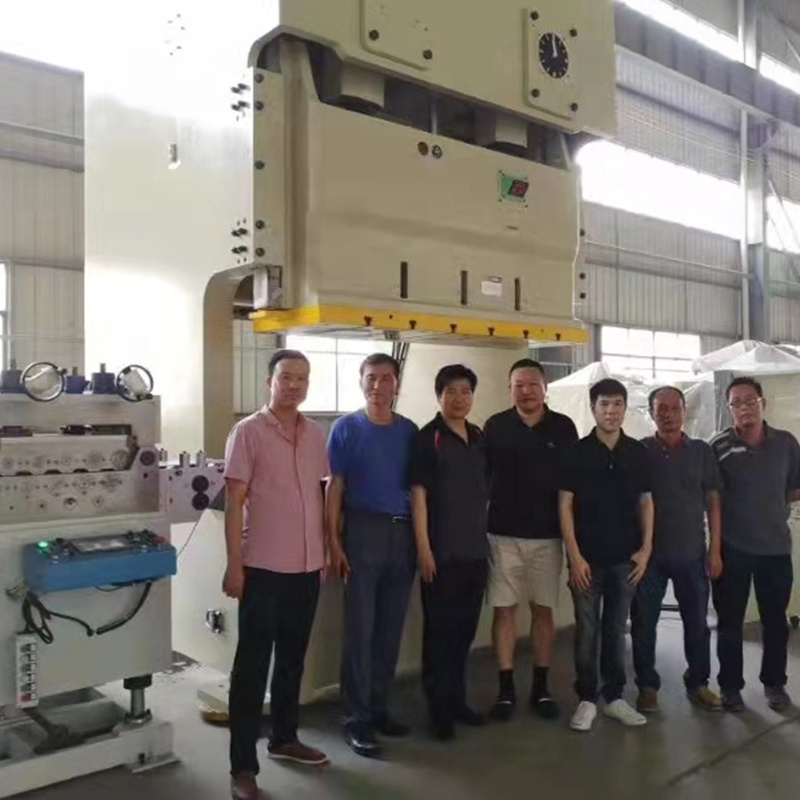

Our Workshop

The machine will be customized the machine for you accroding to drawings or the samples,please feel free to contact with us.