- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

2

-

Voltage:

-

110V/220V/240V/380V, 110V/220V/240V/380V

-

Power:

-

5.5 ~27.5KW, 5.5 - 27.5

-

Weight:

-

800 KG

-

Processing Types:

-

distillery, chemical

-

Product Name:

-

Mixing tank

-

Material:

-

SS304/SS316L

-

Capacity(L):

-

100L - 3000L

-

Weight(kgs):

-

80 - 800

-

Surface:

-

Mirror polishing, semi bright

-

Heating Method:

-

electric/steam/gas

-

Application:

-

distillery, chemical

Quick Details

-

Core Components:

-

Tank body

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

JUNTENG

-

Model Number:

-

2

-

Voltage:

-

110V/220V/240V/380V, 110V/220V/240V/380V

-

Power:

-

5.5 ~27.5KW, 5.5 - 27.5

-

Weight:

-

800 KG

-

Processing Types:

-

distillery, chemical

-

Product Name:

-

Mixing tank

-

Material:

-

SS304/SS316L

-

Capacity(L):

-

100L - 3000L

-

Weight(kgs):

-

80 - 800

-

Surface:

-

Mirror polishing, semi bright

-

Heating Method:

-

electric/steam/gas

-

Application:

-

distillery, chemical

Related Products

Product Parameter

|

Model

|

Working Volume

|

Working Volume

|

Diameter

|

Height

|

Motor Power

|

|

|

(L)

|

(Gallon)

|

(mm)

|

(mm)

|

(KW)

|

|

JT-MV100

|

100

|

26

|

500

|

730

|

0.37

|

|

JT-MV200

|

200

|

53

|

700

|

850

|

0.37

|

|

JT-MV300

|

300

|

79

|

800

|

980

|

0.55

|

|

JT-MV500

|

500

|

132

|

900

|

1100

|

0.55

|

|

JT-MV1000

|

1000

|

264

|

1000

|

1350

|

0.75

|

|

JT-MV2000

|

2000

|

528

|

1600

|

1800

|

1.5

|

|

JT-MV3000

|

3000

|

794

|

1600

|

2600

|

2.2

|

|

JT-MV4000

|

4000

|

1058

|

1600

|

2900

|

3

|

|

JT-MV5000

|

5000

|

1323

|

1800

|

3150

|

3

|

Product Display

Key Components

High Quality and Nicely Built

Mixing tank

for Your Trust and Honored Choice!

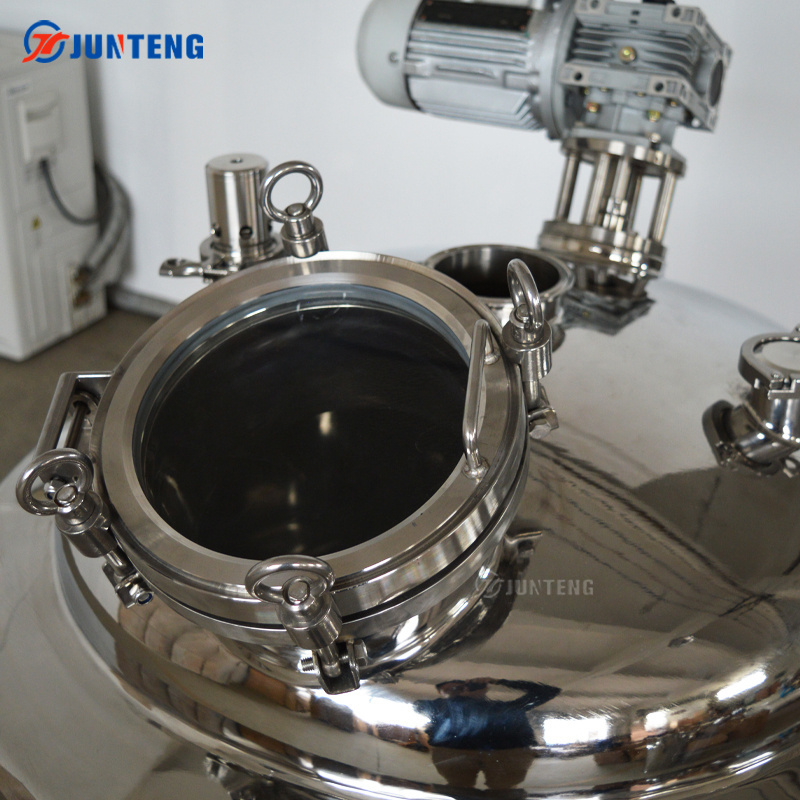

01, Glass Manhole

The high pressure sight glass manhole is a way for raw material loading and deep cleaning. The operator can see the mixing process inside the boiler clearly. So that all reactions changes inside the tank can be monitored closely and timely. This manole can be made in stainless steel with a sight glass union too per clients requirement.

But all these manles should bear high pressure in order to avoid any air leaks during the production process.

02, Ex-proof Electric Motor

The Ex-proof elctric motor is connected with a gear box to drive the mixing blade to stir the raw materials inside the tank. The raw materials can be liquid, paste or sometimes powder. The Ex-proof electric motor is very important for some specific industries, such as alcohol distillation and chemicals.

Actually, there are many different kinds of mixing blades, such as paddle mixer, anchor mixer, magnetic mixer, spiral ribbon mixer etc.. The customers can choose the most suitable one per the requirement of application.

The liquidmeter is usually required if you are going to proceed the liquid materials. You can check and closely monitor the latest liquid level of the material inside the tank during the production process. There are common sight glass liquidmeter, magnetic flap level gauge and so on.

05, Control Panel

The operator can control the raw material loading, heating, mixing and transfer easily by the control panel. The whole process can be done semi-automatic and fully automatic per clients requirement.

Production Process

Hot Searches