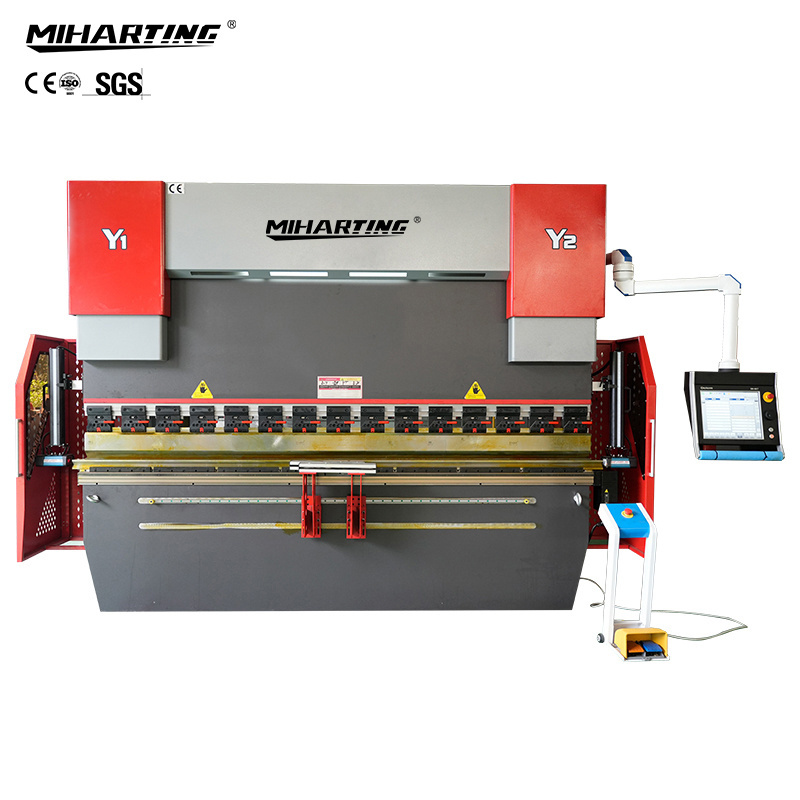

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Miharting

-

Weight (KG):

-

5800

-

Product name:

-

Sheet metal press brake

-

Keyword:

-

Brake Press Machine

-

Application:

-

Stainless Plate Bending

-

Name:

-

Hydraulic Bending Machine

-

Material:

-

Sheet Metal/carbon steel

-

throat depth:

-

400mm for 400t/4000 bending machine

-

power for Press brake:

-

30kw

-

Function:

-

Metal bender

-

Usage:

-

sheet metal bending

Quick Details

-

Bending Thickness(mm):

-

1.2 - 10 mm

-

Bending Length(mm):

-

4000 mm

-

Marketing Type:

-

New Product 2022

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Miharting

-

Weight (KG):

-

5800

-

Product name:

-

Sheet metal press brake

-

Keyword:

-

Brake Press Machine

-

Application:

-

Stainless Plate Bending

-

Name:

-

Hydraulic Bending Machine

-

Material:

-

Sheet Metal/carbon steel

-

throat depth:

-

400mm for 400t/4000 bending machine

-

power for Press brake:

-

30kw

-

Function:

-

Metal bender

-

Usage:

-

sheet metal bending

Product Introdution

1.Overall Welded And Processed Structure, The Frame Is Analyzed Using Ansys Finite Element Analysis Software To Ensure The

Reliability Of The Machine And The Precision Of The Machine.

2. Electric Hydraulic Proportional Servo Synchronization, Ensuring Repeated Accuracy.

3.The Standard 4+1 Axes, Imported Ball Screw And Linear Guide Rail Ensure The Speed And Accuracy Of The Backagauge, And More Multi-Axes Backagauge Mechanism Can Be Used According To Customer Requirements.

4.The Hydraulic System Adopts The Integrated Control System Imported From Germany, Which Reduces The Installation Of

Pipelines,Ensures The Stability Of The Machine, And The Appearance Is Simple And Beautiful.

5.C-Type Plates Are Installed On Both Sides Of The Machine Frame, And The High-Precision Grating Ruler Is Mounted On The C-Type Plate So As To Avoid The Influence Of Deformation Of The Fuselage On The Bending Accuracy During Bending.

6.Automatic Mechanical Crowing Mechanism Eliminate The Influence Of Slider Deformation On Workpiece Quality.

7.Cnc Controller Automatically Adjusts The Compensation Amount, And The Operation Is Convenient And Accurate.

8.Special Cnc Controller Normally Uses Holland Delem, Italy Esa, Swiss Cybelec.

Reliability Of The Machine And The Precision Of The Machine.

2. Electric Hydraulic Proportional Servo Synchronization, Ensuring Repeated Accuracy.

3.The Standard 4+1 Axes, Imported Ball Screw And Linear Guide Rail Ensure The Speed And Accuracy Of The Backagauge, And More Multi-Axes Backagauge Mechanism Can Be Used According To Customer Requirements.

4.The Hydraulic System Adopts The Integrated Control System Imported From Germany, Which Reduces The Installation Of

Pipelines,Ensures The Stability Of The Machine, And The Appearance Is Simple And Beautiful.

5.C-Type Plates Are Installed On Both Sides Of The Machine Frame, And The High-Precision Grating Ruler Is Mounted On The C-Type Plate So As To Avoid The Influence Of Deformation Of The Fuselage On The Bending Accuracy During Bending.

6.Automatic Mechanical Crowing Mechanism Eliminate The Influence Of Slider Deformation On Workpiece Quality.

7.Cnc Controller Automatically Adjusts The Compensation Amount, And The Operation Is Convenient And Accurate.

8.Special Cnc Controller Normally Uses Holland Delem, Italy Esa, Swiss Cybelec.

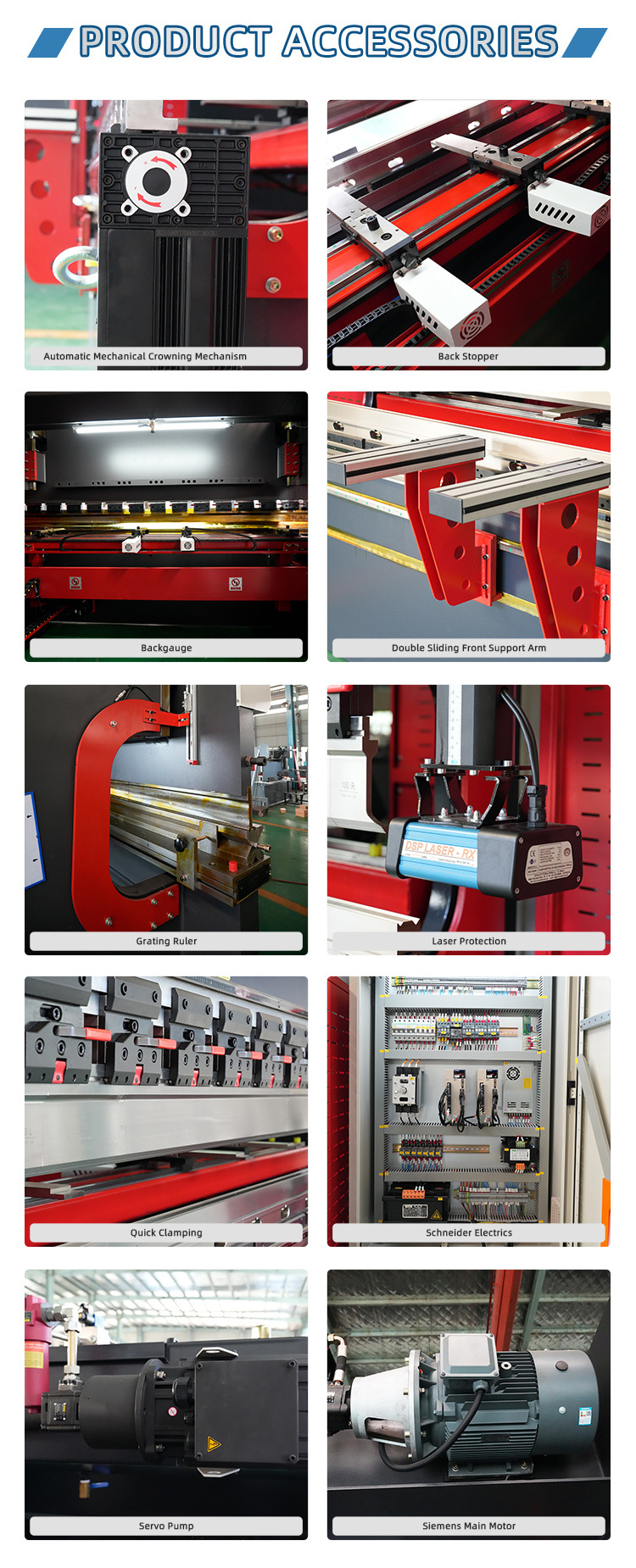

Standard Configuration

1.Automatic Mechanical Crowning Mechanism

2.Siemens Main Motor Germany Brand/Sunny Gear Pump USA Brand/Rexroth Valve Germany Brand

3.High Precision Quick Release Clamping

4.The High-Precision Grating Ruler Is Mounted On The C- Type Plate

5.Double Sliding Front Support Arm Installed On The Linear Guide, Movable Easy

6.The Standard X And R Axes Backgauge

7.SVP one-way Servo Pump Control Technology ( OPTIONAL)

* Change oil pump motor to servo motor, real-time control over motor speed, reduces idle work, achieves the energy saving, high

efficiency and stability

* SVP is the hydraulic bending control technology of energy-saving type, with best price/performance ratio

8.The Stopper Move Left And Right On Two Linear Guide

9.Laser Protection Device

Imported Laser Safe laser protection device,a world-renowned brand,is fully in line with the EU CE standard.

2.Siemens Main Motor Germany Brand/Sunny Gear Pump USA Brand/Rexroth Valve Germany Brand

3.High Precision Quick Release Clamping

4.The High-Precision Grating Ruler Is Mounted On The C- Type Plate

5.Double Sliding Front Support Arm Installed On The Linear Guide, Movable Easy

6.The Standard X And R Axes Backgauge

7.SVP one-way Servo Pump Control Technology ( OPTIONAL)

* Change oil pump motor to servo motor, real-time control over motor speed, reduces idle work, achieves the energy saving, high

efficiency and stability

* SVP is the hydraulic bending control technology of energy-saving type, with best price/performance ratio

8.The Stopper Move Left And Right On Two Linear Guide

9.Laser Protection Device

Imported Laser Safe laser protection device,a world-renowned brand,is fully in line with the EU CE standard.

Specification

|

Item

|

Unit

|

6325

|

10032

|

10040

|

12532

|

12540

|

16032

|

16040

|

20032

|

|

Capacity

|

KN

|

630

|

1000

|

1000

|

1250

|

1250

|

1600

|

1600

|

2000

|

|

Table Length

|

mm

|

2500

|

3200

|

4000

|

3200

|

4000

|

3200

|

4000

|

3200

|

|

Between Columns

|

mm

|

2100

|

2600

|

3100

|

2600

|

3100

|

2600

|

3100

|

2600

|

|

Daylight Opening

|

mm

|

420

|

460

|

460

|

460

|

460

|

460

|

460

|

460

|

|

Ram Stroke

|

mm

|

150

|

200

|

200

|

200

|

200

|

200

|

200

|

200

|

|

Throat Depth

|

mm

|

320

|

400

|

400

|

400

|

400

|

400

|

400

|

400

|

|

Approach Speed

|

mm/s

|

180

|

180

|

180

|

180

|

180

|

160

|

160

|

150

|

|

Working Speed

|

mm/s

|

12

|

10

|

10

|

10

|

10

|

9

|

9

|

9

|

|

Return Speed

|

mm/s

|

170

|

160

|

160

|

160

|

150

|

150

|

140

|

140

|

|

Main Motor Power

|

kw

|

5.5

|

7.5

|

7.5

|

7.5

|

7.5

|

11

|

11

|

15

|

|

X axes stroke

|

mm

|

500

|

500

|

500

|

500

|

500

|

500

|

500

|

500

|

|

X axes speed

|

mm/s

|

300

|

300

|

300

|

300

|

300

|

300

|

300

|

300

|

|

R axes stroke

|

mm

|

200

|

200

|

200

|

200

|

200

|

200

|

200

|

200

|

Our campany

Hot Searches